The PA-22 PS is a compact programmable pressure switch and pressure transmitter. This transmitter provides continuous analog 0,5…4,5 V signal for process monitoring and switch functions to activate control relays or alarms at predetermined pressure levels. The PA-22PS offers two independent switches for HI/LO control functions. These solid state switches can be factory programmed to either NPN or PNP outputs and are not subject to wear.

The optional DV-22 PP programmer (external supply) allows the user to easily change settings. This programmer can also be linked to a laptop/PC for use with Keller’s “pressure switch console” software.

Figure 1. PA-22 PS Pressure Switch.

The following characteristics can be programmed either at the factory, or by the user via the DV-22 PP:

- Hysteresis / window function

- Normally open / normally closed

- Switching delay.

It is also possible to monitor and record pressure sequences on the PC for application diagnostic purposes using the DV-22 PP programmer unit and PC- software. The PA-22 PS provides a compact, sturdy design that is ideal for harsh environments.

Figure 2. DV-22 P Programming Unit (Optional).

The specifications are provided below:

| Pressure Ranges absolute |

4 bar to 400 bar |

| Overpressure |

1,5 x pressure range |

| Error Band (0…80 °C) * |

2 %FS |

| Operating Temperature |

-40…125 °C |

| Measuring Interval |

~ 1 ms |

| Switch Delay |

0…5 s (steps of 20 ms) |

| Supply |

8…40 VDC |

| Analog Output |

0,5…4,5 V, load resistance > 30 kΩ |

| Switch Outputs |

2 x PNP/NPN selectable, max. load: 0,5 A |

| Smallest Resolution of Switch Points |

1/820 FS (0,12 %FS) |

| Pressure Connection |

G 1/4” with HEX22 |

| Electrical Connection |

M12, 5 Pol |

| Protection |

IP 67 (with corresponding counter-plug) |

| Width x Height |

26 x 53 mm |

| Weight |

~ 60 g |

| Optional Accessories |

Programmer dV-22 PP to program the pressure switch. The programmer is connected to the PC via converter cable K-107 or K-104B. |

Connector Pin Assignment

Connector pin assignment M12 is done as follows:

Pin 1: +VCC (8…40 V DC)

Pin 2: Switch output 2

Pin 3: GND

Pin 4: Switch output 1

Pin 5: Analog output.

In case a meter is connected to the analog output, it must have an internal resistance of at least 30 kΩ. Even though the pressure switches are already configured at the factory, the configuration can be changed via the dV-22 PP programmer. Time delay can only be changed with a PC / laptop running the “Pressure Switch Console” software.

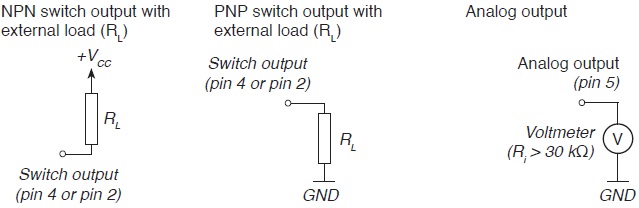

Connection Diagram

The connection diagram is shown below:

Figure 3. Pressure Switch PA-22 PS / PAA-22 PS.

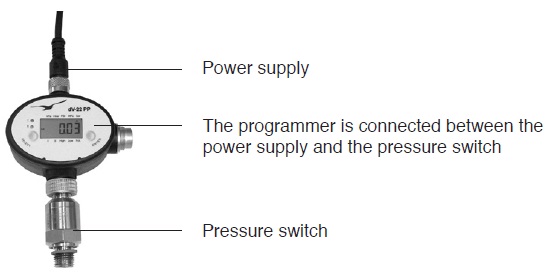

Programmer dV-22PP

It is possible to change the configuration of the pressure switch with the dV-22 PP programmer.

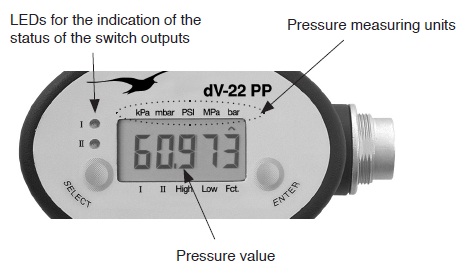

Figure 4. Programmer dV-22PP.

Programming / Pressure Switch Configuration

The connected pressure switch can be programmed either by keystroke with the programmer alone or with a PC / laptop connected to the programming device.

Programming with the programmer dV-22

The programmer requires a power supply. It is operated with the two keys.

Figure 5. Programming with the dV-22.

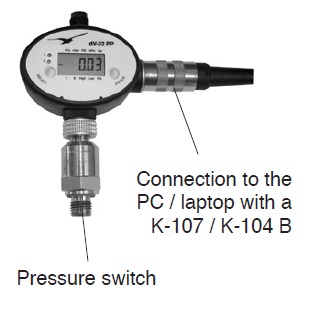

Programming with a PC / Laptop

In case an interface cable from KELLER (K-107 / K-104 B) is connected to the programmer, programming can be carried out with a PC / laptop using the “Pressure Switch Console” software. Here, the power supply for the programmer comes directly via the converter.

Figure 6. Software (Pressure Switch Console) for comfortable programming with a PC / laptop.

Connection to PC (Binder Plug)

The connector plug is used to communicate with a PC / laptop. The interface cable (K-107 / K-104B) can be connected here.

Pressure switch connection M12 socket

The pressure switch is connected to the M12 socket. If required, an M12 extension cable (5-pole) can be used between the programmer and the pressure switch.

Display

In the regular mode, the programmer displays the actual pressure value of the pressure switch (only for pressure switches having an analog output), and the status of the switch outputs with LED’s.

Menu Navigation

Navigation in the display menu is made with the two keys SELECT and ENTER.

Key Functions

SELECT: Navigate forwards within the menu.

ENTER: Select the menu item.

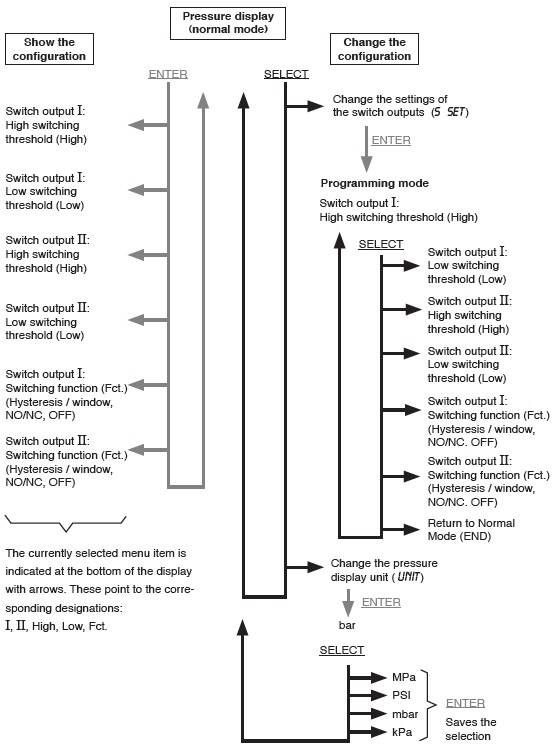

Menu Structure

Programming mode

The programming mode enables the switching thresholds and switching functions to be set.

Example: Changing the switching threshold.

The switching threshold to be changed is selected with SELECT. The selected menu item is indicated at the bottom of the display: I, II, Low, High, Fct. The arrows point to the corresponding designations. For example: if the arrows point to I and High --> the high switching threshold of switch output 1 can be changed.

By pressing ENTER or the flashing arrow, this value is then released. The value is decreased with SELECT and increased with ENTER. In case no button is pressed for about 5 seconds, the programming device saves the value displayed to the pressure switch (the arrows stop flashing).

Switching functions (Fct.)

Various functions can be configured for the switch outputs.

| Hysteresis (H): |

When the high switching threshold is high, the output closes. It only opens again when the value goes below the low switching threshold. Application example: 2-point controller. |

| Window (F): |

The switch output is closed between the low and high switching thresholds. Outside this range it is open. Application example: Alarm when the pressure is outside a defined range. |

| Normally Open (no): |

The switch contact is normally open. |

| Normally Closed (nc): |

The switch contact is normally closed (inverse of NO). |

| Off (OFF): |

The switch contact is always open. |

In order to change the corresponding switching function, press ENTER in the programming mode repeatedly until the required function is displayed. Press SELECT to go to the next menu item: this simultaneously saves the displayed switching function to the pressure switch.

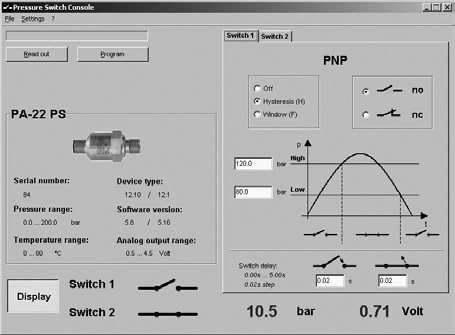

“Pressure Switch Console” Software

In case the programmer is connected to a PC / laptop via a interface cable (K-107 / K-104 B), the configuration of the pressure switch can easily be made with the “Pressure Switch Console” program.

Setting the serial port

The serial connection that is used to connect the programmer to the PC / laptop must be entered under Edit / Port. In case there are no COM numbers, the connection must be set with “Set COMPort“.

Selection of the pressure measuring unit

The pressure unit (bar, PSI or MPa), in which the program displays the pressure values, can be selected.

Read-out and program the pressure switch.

By pressing “Read out”, the data of the pressure switch connected to the programmer is recoded. The configurations (switching thresholds, switching functions, switching time delays) can now be changed for the switch outputs 1 and 2.

Press “Program” to load the changed values back to the pressure switch. Due to the low resolution of the pressure switch, the pressure values displayed may change slightly. The nearest possible value is set.

When programming is complete, the pressure switch can be disconnected and used: the configuration in the pressure switch remains stored.

Using the console, the actual pressure value of the pressure switch and the status of the switch outputs can be displayed. Press “Display” to show these values. However, the actual pressure value can only be displayed if the pressure switch has an analog output.

A pressure trend curve can be displayed and recorded graphically with the KELLER “Read30” software.

About Keller UK

KELLER is Europe's largest manufacturer of isolated piezoresistive pressure sensors and pressure transmitters. KELLER are a world leader in pressure sensing technology continually developing new materials and manufacturing processes, that is why this company remain successful.

This Company introduces a comprehensive range of products, from simple Pressure Capsules, to fully compensated digital pressure transmitters, also low- cost industrial pressure transmitters, digital pressure gauges, recording digital manometers. Modern advanced production techniques enable KELLER to offer competitive pricing for medium and high volume production orders. Customer engineered special products are easily accommodated.

KELLER supply Pressure Sensors to all industries and applications and are specialist in the following areas: Refrigeration, Oil & Gas 'down-hole', Water Depth, Hydraulics, Autoclave Sterilisers, Oceanology.

This information has been sourced, reviewed and adapted from materials provided by Keller UK.

For more information on this source, please visit Keller UK.