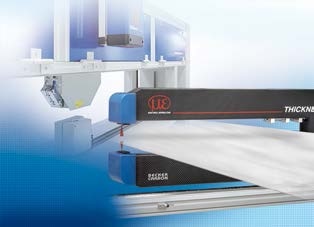

The thicknessSENSOR from Micro Epsilon for laser-optical thickness measurement opens up additional diverse application possibilities in terms of non-contact thickness measurement. The sensor functions with very high precision along with a compact design and ease of use. It measures without contact, which makes it wear-free.

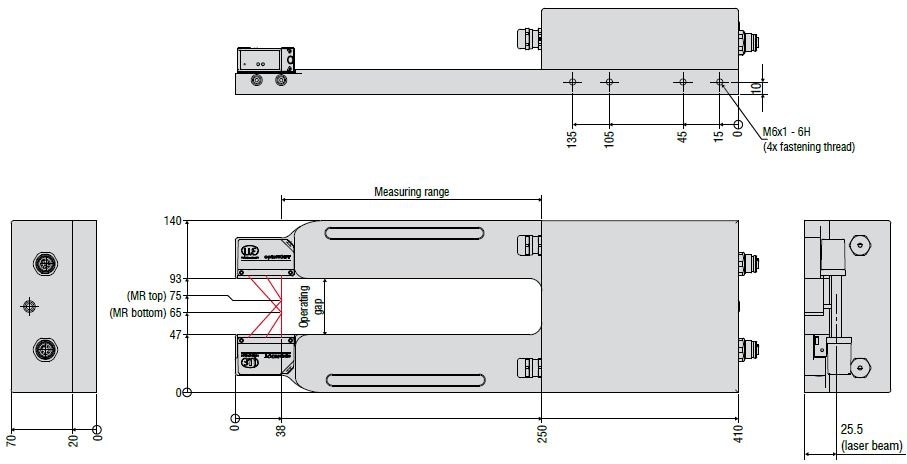

The fully assembled system allows easy integration without any requirement for complex sensor alignments. Due to its compact design, the system can also be easily implemented in a confined installation space. This new entry-level sensor class provides high precision thickness measurements followed by an unparalleled price/performance ratio.

The thicknessSENSOR is used for thickness measurement of plate and strip material such as films and metals. The thickness of the material is detected according to the difference principle. Two laser triangulation sensors are installed opposite to each other on a stable frame, and measure against the material surface without touching each other.

The evaluation unit is integrated into the frame, and calculates the thickness values and output these through different interfaces.

The intuitive web interface provides the thicknessSENSOR with unique ease of use, and allows the user to load individual presets for the respective measurement operation. The setup management feature is capable of storing and exporting up to eight user-specific sensor setting. The measurement operation can be enhanced with the help of signal peak selection, video signal display, and freely adjustable signal averaging.

The key features of the thicknessSENSOR are as follows

- Simple to integrate and operate

- Non-contact and wear-free measurement

- Instantly ready for use due to perfectly harmonized components

- Compact system

- Precise measurement results with high dynamic

The new thicknessSENSOR is used for precise thickness measurement of plate and strip material. This completely assembled system consists of a stable frame on which two laser triangulation sensors are fixed. These triangulation sensors detect the material thickness according to the difference principle.

The evaluation unit is incorporated into the frame, and calculates the thickness values and outputs these through different interfaces.

Compact Design and High Precision

The thicknessSENSOR enables turnkey thickness measurement coupled with an unparalleled price/performance ratio. With its extremely compact design, this system can also be fitted into a confined installation space.

The two sensors are well adjusted to each other in terms of their mounting conditions, providing high measurement accuracy. The sensors can be calibrated at any time with the help of a calibration target.

Unique Ease of Use

An intuitive web interface is used to operate the thicknessSENSOR. Using predefined presets, the settings for the measurement task can be chosen quickly. Different configuration and set up possibilities allow the user to easily adapt the sensor, for example to perform dynamic measurements.

The setup management is capable of storing and exporting up to eight user-specific sensor settings. The freely adjustable signal averaging and a signal peak selection allow the experienced user to enhance the measurement task.

FSO = Full scale output

High Performance Sensors Made by Micro-Epsilon

The following are the high performance sensors manufactured by Micro Epsilon:

Sensors and systems for displacement and position

Sensors and measurement devices for non-contact temperature measurement

2D/3D profile sensors (laser scanner)

Optical micrometers, fiber optic sensors and fiber optics

Color recognition sensors, LED analyzers and colour online spectrometer

Measurement and inspection systems

Laser triangulation - operating principle