The newly developed optoNCDT 1420 laser triangulation sensors from sensor specialist Micro-Epsilon are in a class of their own. The Smart sensor concept with compact size and integrated web interface is unique worldwide. These sensors are considered to be attractive because of their exceptional price/performance ratio.

optoNCDT laser sensors based on the triangulation measuring principle perform non-contact displacement, position and distance measurements. These new compact optoNCDT 1420 triangulation sensors achieve high measurement accuracy even with measuring rates of up to 4 kHz.

The connection is made either through a 0.3 meter-length pigtail with M12 connector or through 3 meter-length cable with open ends. These sensors provide an intelligent surface regulation just like all triangulation sensors from Micro-Epsilon.

Stable results are ensured by the Auto Target Compensation (ATC), regardless of changing colors or brightness of the target. The high-performance optical system projects the small light spot sharply onto the measurement object which also allows detecting even the smallest components in a reliable manner.

The sensor can be integrated into plant or machine control systems using varied output signals. Installation is made easy as a separate controller is not needed. In addition to analog voltage and current outputs, a digital RS422 interface provides distance information from the sensor.

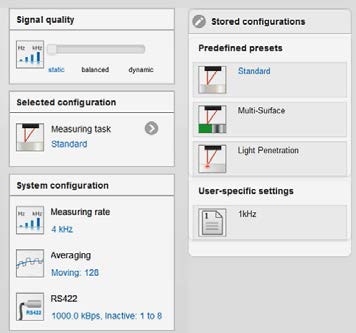

An intuitive web interface is used to operate all optoNCDT 1420 laser sensors. Fast sensor parameter set up is enabled by presets and a quality slider for the selection of the measurement task. Additionally, it is possible to store and export eight user-specific sensors settings in the setup management.

Loading these individual sensor settings allows fast parameter set up, e.g. for high volume applications. The signal peak selection, the video signal display and a freely adjustable signal averaging help to optimize the measurement task. Rapid commissioning for simple measurement tasks is enabled by the multifunction button.

- Ideal for serial and OEM applications

- Compact design with integrated controller

- Measuring rate up to 4 kHz

- Analog (U/I) and digital output

- Trigger input/teach-in zero-setting/mastering

- Configuration via web interface or Plug & Play

- Application-specific presets and individual setups

- Auto Target Compensation

The optoNCDT1420 offers a unique combination of performance, size, speed and application versatility in the range of compact triangulation sensors. The lightweight sensor with an integrated controller is designed for dynamic measurements and can also be integrated into restricted installation space.

The selectable connector type, i.e. pigtail or cable, together with compact size minimizes the sensor installation effort. The optoNCDT 1420, just like all triangulation sensors from Micro-Epsilon, provides an intelligent surface regulation.

This is how stable results, regardless of changing colors or brightness of the target, are ensured by the Auto Target Compensation (ATC). The small light spot is sharply projected by the high-performance optical system projects onto the measurement object, which enables even the smallest components to be detected in a reliable manner.

Highest Precision in a Minimum of Space

Compact size together with low weight opens up new fields of application. A wide range of output signals help integrate the sensor into plant or machine control systems. In addition to analog voltage and current outputs, a digital RS422 interface also provides distance information from the sensor.

The requirements for use in high volume and OEM applications are met by the optoNCDT 1420 due to the selectable setting and evaluation possibilities. A high measurement accuracy is achieved by the compact triangulation sensor even with measuring rates of up to 4 kHz.

Compact laser triangulation sensors

Unique Ease of Use, Individual Results

An intuitive web interface is used to operate all optoNCDT 1420 models. Presets for the selection of the measurement task allow rapid sensor parameter set up. Precise measurement results are easily achieved without any complex optimization through the use of Standard Changing surfaces and Material with penetration settings.

Additionally, up to eight user-specific sensors settings can be stored and exported in the setup management. This is how stored sensor settings can be effortlessly transferred to other sensors. An extended web interface providing several additional functions is offered by the optoNCDT. The signal peak selection, video signal display, and a freely adjustable signal averaging enable to optimize the measurement task.

The region of interest (ROI) function allows e.g. for interfering signals in the background to be filtered out. Therefore the remaining signal peak is optimally corrected.

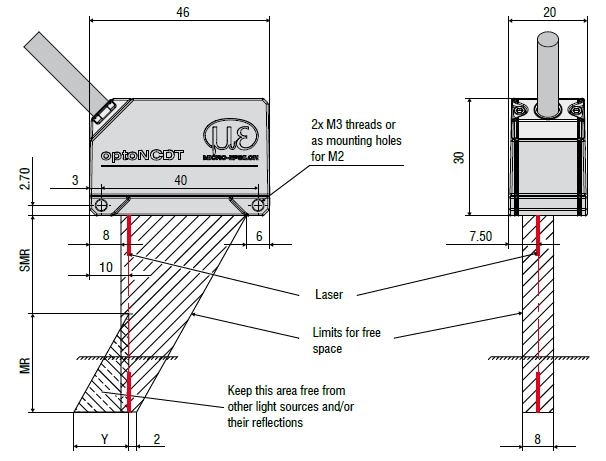

| MR |

SMR |

Y |

| 10 |

20 |

10 |

| 25 |

25 |

21 |

| 50 |

35 |

28 |

| 100 |

50 |

46 |

| 200 |

60 |

70 |

High Performance Sensors Made by Micro-Epsilon

Sensors and systems for displacement and position

Sensors and measurement devices for non-contact temperature measurement

2D/3D profile sensors (laser scanner)

Optical micrometers, fiber optic sensors and fiber optics

Color recognition sensors, LED analyzers and color online spectrometer

Measurement and inspection systems