The ORT 230/240 Transducer from Sensor Technology provides an ideal means for accurate dynamic measurement of static and rotary torque less than 100 Nm and for bandwidths up to 50 KHz.

The latest TorqSense ORT 230/240 torque sensors succeed the E200 ORT series, with all new electronics that have produced remarkable performance gains in frequency response, resolution, minimized sensor current consumption, and quicker digital data throughput.

Benefits

- Non-contact/brushless measurement

- Low inertia–High-speed capability as electronics are not fixed to the shaft

- High bandwidth

- 200% safe mechanical overload

- Independent electronics module

- Any full-scale torque can be defined within standard range: from 10 mNm to 100 Nm

- Excellent noise immunity

- Works both dynamically and statically—clockwise/anti-clockwise

- Lifetime warranty

TorqSense ORT 230 Series Transducers Offer:

- Fixed voltage or current analog outputs (one for torque and the other for power or speed) for interfacing with analog instrumentation

- Sensors to track shaft temperature for improved accuracy and compensation

- Basic “Sensor status” output pin

- BIT Self-diagnostics for the manufacturers to know that the transducer’s speed ratings, torque, and calibration due date have not been exceeded

Whereas, TorqSense ORT 240 Series Transducers Offer:

- Digital outputs, such as CAN bus, RS232, and USB, for interfacing with latest laptops and instrumentation

- Transducer configuration software to enable users to modify transducer variables

- Digital input for setting up transducer via PC

- 2 x user-selectable voltage or current analog outputs (one for torque and the other for power, speed, or peak torque) for interfacing with analog instrumentation

- BIT Self-diagnostics for informing users whether data is reliable and if the transducer’s speed ratings, torque, and calibration due date have not been exceeded

- Can link up to 10 transducers using USB

- Basic “Sensor status” output pin

- Sensors to track shaft temperature for improved accuracy and compensation

Technology

A widely developed measurement standard is used, where the intensity of light beams is measured using photovoltaic detectors, and the electrical output precisely indicates the applied torque conveyed by the shaft.

This technique enables a transducer to detect torque bi-directionally, have a rapid electrical and mechanical response, low inertia, and freedom from brushes or multifaceted electronics. The absence of brush gear enables a high-speed process with an uninterrupted rating of up to 30,000 RPM standard. Additional increases in RPM are available as an option based on the size of the shaft.

The torque shaft has low-compliance maximum-torsion deflection at full-scale deflection. The lamps supplying the light source are chosen to guarantee long life and high stability while the light intensity is automatically regulated inside the transducer body by a monitor cell.

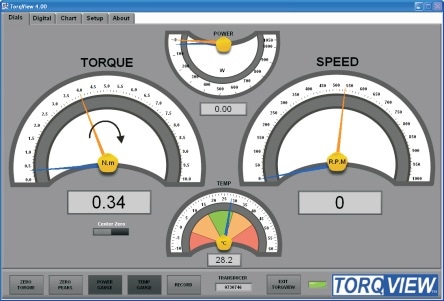

TorqView Software

TorqView is a user-friendly advanced torque monitoring software, available to help data recording and instrumentation displays that interface with Windows-based PCs. The features include three types of displays, text files matching Matlab and Excel, and Real-time chart plotting.

LabView VIs are obtainable for users to create their own process control applications. Users can use DLLs to write their own custom software.

Standard Specifications

| Model |

Torque Range * |

Maximum Speed

(RPM) |

Shaft

Type |

| Minimum |

Maximum |

| ORT230/240-C |

0 to 10 mNm (0 to 1 ozf.in) |

0 to 20 mNm (0 to 3 ozf.in) |

30000 |

Plain |

| ORT230/240-D |

0 to 25 mNm (0 to 3.5 ozf.in) |

0 to 100 mNm (0 to 10 ozf.in) |

30000 |

Plain |

| ORT230/240-E |

0 to 150 mNm (0 to 15 ozf.in) |

0 to 750 mNm (0 to 100 ozf.in) |

30000 |

Plain |

| ORT230/240-F |

0 to 800 mNm (0 to 7 lbf.in) |

0 to 1 Nm (0 to 10 lbf.in) |

30000 |

Flat |

| ORT230/240-G |

0 to 1.5 Nm (0 to 15 lbf.in) |

0 to 20 Nm (0 to 200 lbf.in) |

20000 |

Keyways |

| ORT230/240-H |

0 to 25 Nm (0 to 250 lbf.in) |

0 to 100 Nm (0 to 1000 lbf.in) |

15000 |

Keyways |

* Calibration is possible in any equivalent SI, FPS or MKS units, e.g. gf.cm, lbf.ft, cNm

Transducers may be specified to any torque range between the maximum and minimum for each model.

For example ORT241-C 15 mNm, or ORT231-G 10 Nm.

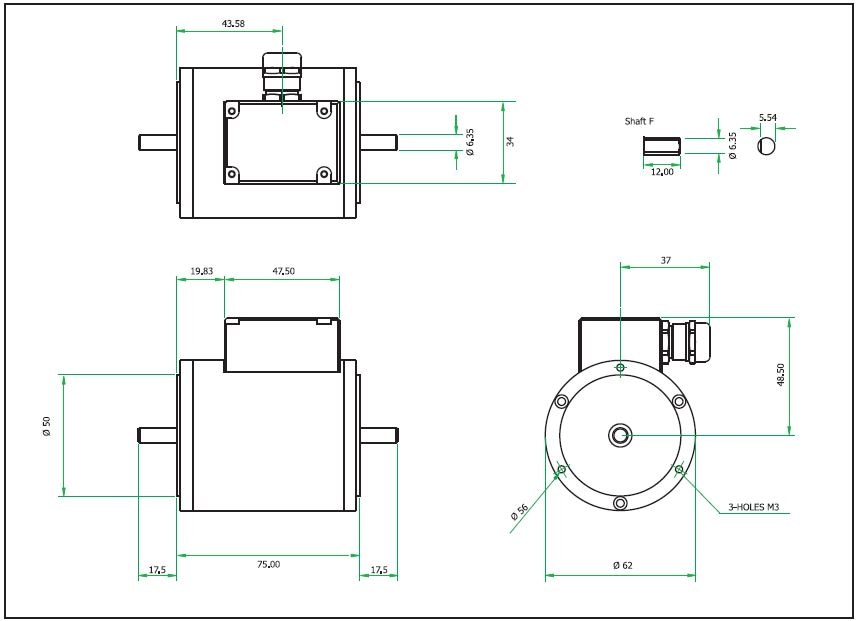

Dimensions—Shaft C, D, E, F (10 mNm to 1 Nm)

| Parameter |

Data |

Units |

| Mechanical Properties |

|

| Torque (Max) |

20 mNm (3 ozf.in) |

100 mNm (10 ozf.in) |

750 mNm (100 ozf.in) |

1 Nm (10 lbf.in) |

|

| Shaft code |

C |

D |

E |

F |

|

| Speed (Max) |

30000 |

30000 |

30000 |

30000 |

RPM |

| Shaft type |

Plain |

Plain |

Plain |

Flat |

|

| Max measurable load limit |

120 (of rated torque) |

% |

| Static safe load breakinq |

200 (of rated torque) |

% |

| Transducer weight, approx |

425 |

425 |

425 |

425 |

grams |

Data parameters measured at +20 °C