Dec 1 2016

Researchers from Bochum have developed a sensor that remains fully operational even when an avalanche rolls over it.

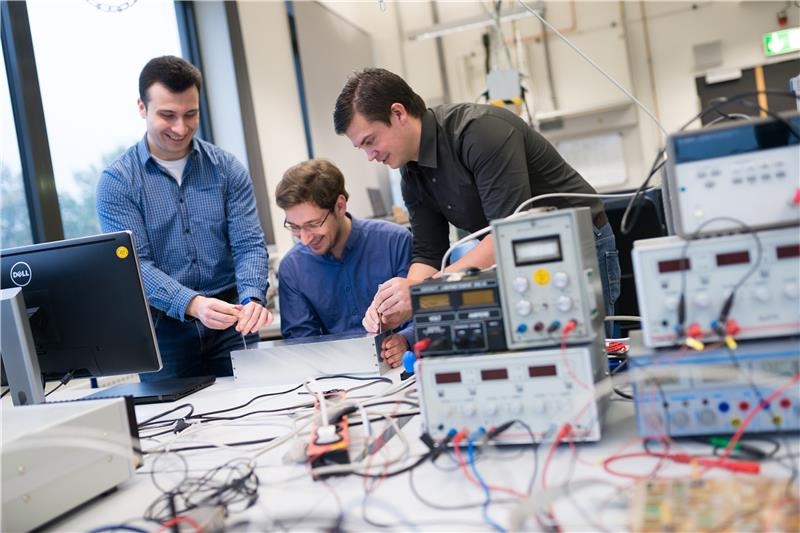

Together, they’ve built a sensor that measures the snow density in avalanches: Patrick Kwiatkowski, Henrik Deis and Christoph Baer (left to right) (Credit: RUB, Kramer)

Together, they’ve built a sensor that measures the snow density in avalanches: Patrick Kwiatkowski, Henrik Deis and Christoph Baer (left to right) (Credit: RUB, Kramer)

A new radar sensor grants insights into the processes inside snow avalanches. It was developed by a team of engineers at Ruhr-Universität Bochum (RUB) headed by Dr Christoph Baer and Timo Jaeschke, in collaboration with colleagues from Innsbruck and Davos. The measuring system has been installed at a test slope in the Swiss canton Valais, where the Swiss Institute for Snow and Avalanche Research intends to use it to perform measurements in winter 2016/17.

The gathered data are to be entered in simulations that will reconstruct the complete processes that happen inside of avalanches in detail. “We don’t know what exactly happens when an avalanche moves down a mountain, because avalanches have only ever been observed from the outside,” says Christoph Baer. The simulation results might contribute to an optimisation of devices offering protection from avalanches.

Measuring snow density

It is principally understood that avalanches are made up of several layers that behave like solids, liquids or dust-containing gases. The new sensor records variations in the snow density in the dust layer. The density affects, for example, the impact pressure of the avalanche that determines its destructive force. The avalanche processes can be correctly simulated in terms of fluid dynamics only if the snow density is known.

The system made in Bochum uses a radar to record how many snow particles are contained in the dust layer. The more snow the layer holds, the more slowly the radar wave propagates. Thus, researchers are able to draw conclusions about the snow density and record it in real time.

Sensor from aircraft-grade aluminium

The sensor consists of aircraft-grade aluminium, as it has to withstand the enormous force of avalanches while performing measurements. It is approximately one metre long and 30 centimetres thick and weighs 70 kilograms. An avalanche has an impact pressure of up to six bar. “That corresponds to a pressure of 3.5 tons – i.e. two cars – applied to a surface area of a sheet in DIN-A4 format,” illustrates Baer. “It rolls directly over our sensor. Making sure that the sensor remains attached to the test pole and supplies usable measurement results is a real challenge.”

The students Patrick Kwiatkowski and Henrik Deis built the sensor while working as graduate assistants at the Institute of Integrated Systems headed by Prof Dr Nils Pohl. At the same department, Timo Jaeschke researches into the deployed millimetre-wave radar system for his doctoral thesis. The principle underlying radar-based density measurement was developed by Christoph Baer for his doctoral thesis at the RUB Institute for Electronic Circuit Technology.

Waiting for the avalanche

Until the end of the year 2016, the team at the Swiss Institute for Snow and Avalanche Research expects the first snowfalls in the closed-off test area Vallée de la Sionne. Should no avalanche occur naturally, it will be triggered through a controlled detonation by the end of the winter.

Source: http://www.ruhr-uni-bochum.de/