Nov 28 2018

Scientists from the National Institute of Standards and Technology (NIST) have reported landmark test results that point toward the fact that a promising category of sensors can be used in high-radiation environments and to promote significant industrial, medical, and research applications.

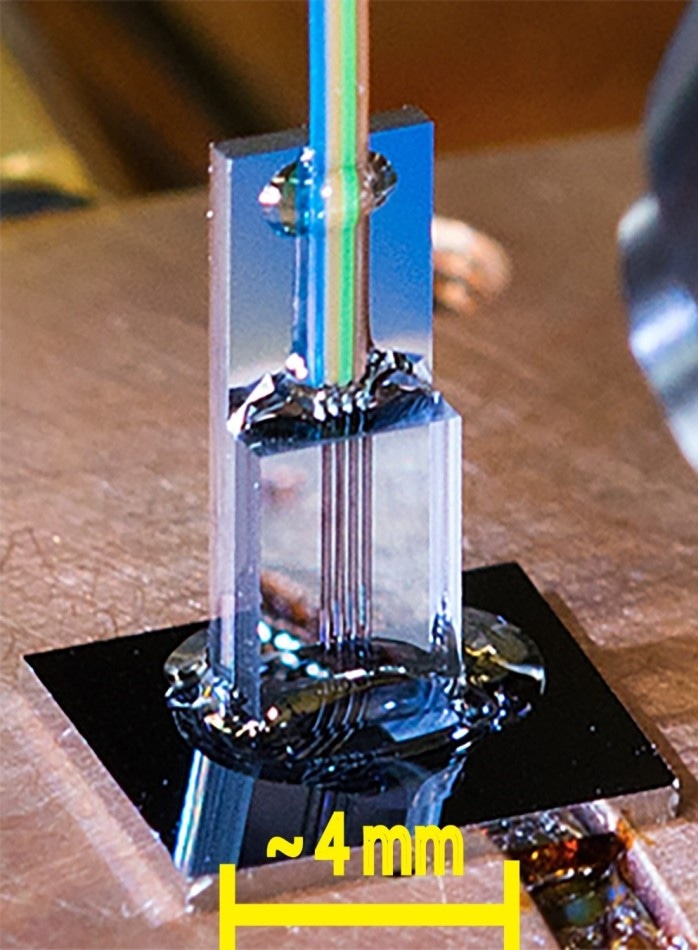

A NIST prototype photonic thermometer. (Image credit: J.L. Lee/NIST)

A NIST prototype photonic thermometer. (Image credit: J.L. Lee/NIST)

Photonic sensors transfer information using light rather than electric currents in wires. They have the potential to measure, transmit, and control streams of photons, usually through optical fibers, and are used to evaluate distance, pressure, magnetic fields, temperature, environmental conditions, and more.

They are appealing due to their low power consumption, small size, and tolerance of environmental variables like mechanical vibration. However, the common opinion has been that high radiation levels would alter the optical properties of silicon, resulting in inaccurate readings.

Therefore, NIST, a long-time pioneer in various areas of photonics research, developed a program to solve those riddles. The results of the test suggest that it would be possible to customize the sensors to measure radiation dose in both clinical radiotherapy and industrial applications. The results of its first round of testing have been reported in Nature Scientific Reports.

Particularly, the NIST results indicate that the sensors could be used for tracking levels of ionizing radiation (with energy sufficient enough to modify the structure of atoms) used in food irradiation to destroy microbes and in medical device sterilization—predicted to be a $7 billion annual market in the United States alone. The sensors could also find prospective applications in medical imaging and therapy, which when combined are estimated to total nearly $50 billion in annual value globally by 2022.

“When we looked at publications on the subject, different labs were getting dramatically different results,” stated project scientist Zeeshan Ahmed, who is part of NIST’s Photonic Dosimetry Project and leader of NIST’s cutting-edge Photonic Thermometry Project. “That was our main motivation for doing our experiment.”

Another motivation was the growing interest in deploying photonic sensors that can function accurately in very harsh environments, such as close to nuclear reactors, where radiation damage is a major concern.

Zeeshan Ahmed, Project Scientist, Photonic Dosimetry Project, NIST.

In addition, the space industry needs to know how these devices would function in high-radiation environments. Are they going to get damaged or not? What this study shows is that for a certain class of devices and radiation, the damage is negligible.

Ronald Tosh, Project Scientist, Photonic Dosimetry Project, NIST.

“We found that oxide-coated silicon photonic devices can withstand radiation exposure up to 1 million gray,” stated Photonic Dosimetry project leader Ryan Fitzgerald, using the SI unit for absorbed radiation. One gray stands for 1 Joule of energy absorbed by 1 kg of mass and corresponds to 10,000 chest X-rays. This is approximately the amount of radiation that would be received by a sensor at a nuclear power plant.

“It’s the upper limit of what our calibrations customers care about,” Fitzgerald said. “So the devices can be assumed to work reliably at industrial or medical radiation levels that are hundreds or thousands of times lower.” For instance, food irradiation ranges from a few hundred to a few thousand gray, and is usually monitored by its impact on pellets of alanine, an amino acid that alters its atomic properties upon exposure to ionizing radiation.

The NIST researchers determined the effects of radiation by exposing two types of silicon photonic sensors to hours of gamma radiation from cobalt-60, a radioactive isotope. In both kinds of sensors, small changes to their physical properties modified the wavelength of the light traveling through them. The devices can be used as highly sensitive strain gauges or thermometers by measuring those variations. This holds good in harsh environments such as nuclear reactors or space flight, only if they continue to function properly when exposed to ionizing radiation.

Our results show that these photonic devices are robust in even extreme radiation environments, which suggests they could be also used to measure radiation via its effects on physical properties of irradiated devices. That should come as good news for U.S. manufacturing, which is anxious to serve the large and growing market for precise delivery of radiation at very small length scales. Photonic sensors could then be developed to measure low-energy electron and X-ray beams used in medical device sterilization and food irradiation.

Ryan Fitzgerald, Project Leader, Photonic Dosimetry Project, NIST.

They will also be of great relevance to clinical medicine, where physicians make efforts to treat cancers and other conditions using the lowest effective levels of radiation targeted on the smallest dimensions to prevent healthy tissue from being affected, including proton, electron, and ion beams.

Achieving that goal requires radiation sensors with extremely high sensitivity and spatial resolution. “Eventually, we hope to develop chip-scale devices for industrial and medical applications that can determine absorbed dose gradients over distances in the range of micrometers and thus provide unprecedented detail in measurements,” said project scientist Nikolai Klimov, where 1 μm is one-millionth of a 1 m, and the width of a strand of human hair is about 100 μm.

The outcomes of the team’s study may have large implications for innovative medical therapies that use extremely narrow beams of protons or carbon ions and medical sterilization processes that employ low-energy electron beams. “Our sensors are naturally small and chip-scale,” stated Fitzgerald. “Current dosimeters are on the order of millimeters to centimeters, which can give erroneous readings for fields that vary over those dimensions.”

In the next stage of the study, the researchers will investigate arrays of sensors at the same time in identical conditions to check whether it is possible to resolve variations in dose over small distances.

Photonic sensors such as the one pictured here transmit information with light instead of electric currents. Recently, NIST scientists tested whether radiation hurts these sensors’ performance. In this setup, scientists put a photonic sensor under a powerful radiation-producing electron beam. The beam travels down a shaft and hits a shutter which can be closed to stop the beam or opened to allow the beam through. When the beam hits the chip, it glows. From the control room next door, physicists can manipulate the beam and monitor the data telling them how the chip is performing. Scientists hope to use these chips someday as sensors in areas with high levels of radiation, such as in space or near equipment used for medical imaging and cancer radiation therapy. (Video credit: Jennifer Lauren Lee/NIST; Music credit: “The Messenger” by Silent Partner)