A recent article in Scientific Reports presents a new approach developed by Chinese researchers to address the limitations of conventional fault detection methods.

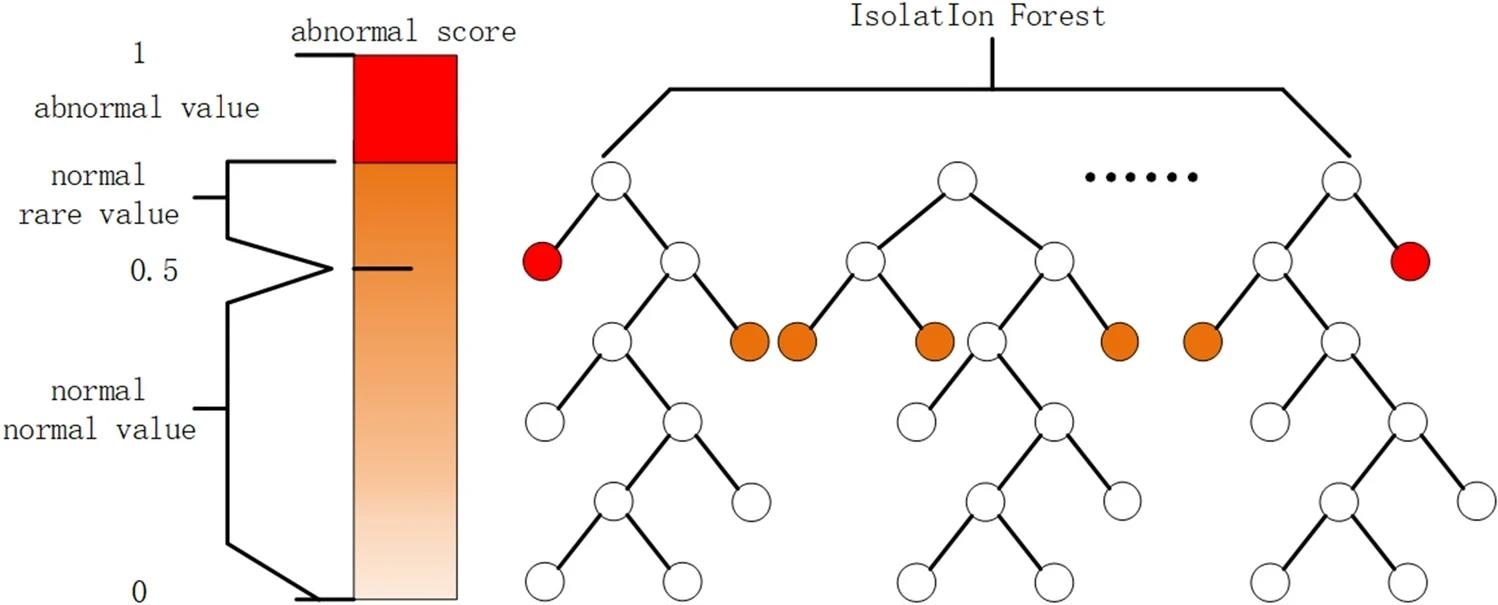

Schematic diagram of abnormal score allocation. Image Credit: https://www.nature.com/articles/s41598-024-60884-z

Schematic diagram of abnormal score allocation. Image Credit: https://www.nature.com/articles/s41598-024-60884-z

This research centers on applying the Incremental Majority Voting Isolation Forest (IMV-IForest) framework in conjunction with a distributed fiber optic sensing system. The goal is to improve the monitoring and early detection of roller faults in conveyor systems.

By leveraging optical signals and advanced anomaly detection algorithms, the research aims to address the limitations of existing methods and improve maintenance practices in industrial settings.

Background

Industrial conveyor systems are vital across multiple sectors, including mining, manufacturing, and logistics, as they ensure the efficient transport of materials and products. Rollers, key components within these systems, support and guide the conveyor belt. However, factors like extended use, environmental conditions, and operational stress can cause rollers to wear and develop faults. These issues can result in downtime, decreased productivity, and increased safety risks.

Traditional fault detection methods in conveyor rollers typically depend on manual inspections or rudimentary monitoring systems, which may fail to catch early signs of malfunctions or predict impending failures. Consequently, there is an increasing demand for advanced fault diagnosis techniques. Such methods would offer real-time monitoring, enable early detection of faults, and support predictive maintenance strategies, significantly enhancing system reliability and efficiency.

The Current Study

The detailed steps in the study methodology are laid out below:

Data Collection: Two months of data collection were conducted on a 600 m long belt conveyor in a mine to gather information on roller behavior. The data included optical signals from distributed fiber optic sensors installed along the conveyor system to monitor roller conditions.

IMV-IForest Framework: The IMV-IForest framework was developed to enhance fault diagnosis in conveyor rollers. This framework involves a continuous segmentation process during the training phase, where the dataset is subsampled and recursively segmented until isolation is achieved or the height limit of the iTree is reached.

Training Phase: During the training phase, the IMV-IForest framework focuses on building multiple iTrees using a subset of the dataset. Each iTree is constructed by randomly selecting a feature and a split point to partition the data. The process continues recursively until the isolation condition is met or the height limit is reached.

Testing Phase: In the testing phase, the anomaly detection process is carried out using the trained iTrees. An anomaly score is calculated based on the average path length of a data point in the iTrees. The anomaly score is compared to a predefined threshold to determine whether a data point is an anomaly or not. This process helps identify faulty rollers based on the variations detected in the optical signals.

Evaluation Metrics: To evaluate the performance of the IMV-IForest framework, metrics such as detection accuracy, false positive rate, and computational efficiency were considered. The framework was compared with traditional IForest and Extended Isolation Forest (E-iForest) methods to assess its effectiveness in fault diagnosis for conveyor rollers.

On-Site Monitoring: The proposed method's effectiveness was validated through on-site monitoring experiments on the belt conveyor system. The results obtained from the experiments were compared with manual testing to assess the accuracy and reliability of the IMV-IForest framework in detecting faulty rollers.

Statistical Analysis: The collected data was statistically analyzed to identify patterns and trends related to roller faults. The analysis included the distribution of anomaly scores, comparison of fault data with normal data, and determination of an anomaly score threshold for accurate fault detection.

Results and Discussion

The study successfully implemented the IMV-IForest framework for fault diagnosis in conveyor rollers based on a distributed fiber optic sensing system. The research demonstrated the effectiveness of the proposed method in detecting variations indicative of roller faults. The comparison with traditional IForest and E-iForest methods highlighted the superior performance of the IMV-IForest framework in terms of accuracy and computational efficiency.

The on-site monitoring experiments provided valuable insights into the practical application of the IMV-IForest framework, showcasing its ability to detect faulty rollers with high accuracy. By comparing the results of the automated fault diagnosis with manual testing, the study confirmed the reliability and effectiveness of the proposed method in enhancing roller monitoring technology. The analysis of anomaly scores, distribution patterns, and comparison results further supported the robustness of the IMV-IForest framework in identifying roller faults early and accurately.

Conclusion

The study's results underscore the importance of continuous innovation in fault diagnosis techniques for critical components like conveyor rollers. This approach offers a promising solution for improving roller monitoring technology and enhancing maintenance practices in conveyor systems.

Moving forward, further research and development in fiber optic sensing systems and anomaly detection algorithms will be crucial to advancing maintenance practices and ensuring the smooth operation of industrial conveyor systems. The proposed IMV-IForest framework stands as a significant step towards intelligent and proactive maintenance strategies in the mining and material handling industries.

Journal Reference

Xie, M., Li, B., Ma, S. et al. (2024). Research on roller monitoring technology based on distributed fiber optic sensing system. Scientific Reports 14, 10048. https://doi.org/10.1038/s41598-024-60884-z, https://www.nature.com/articles/s41598-024-60884-z

Article Revisions

- May 16 2024 - Title changed from "IMV-IForest: Advanced Conveyor Roller Fault Detection" to "Fiber Optic Sensing: A Breakthrough in Conveyor Fault Diagnosis"