Sep 14 2012

NASA’s newest orbital X-ray telescope technology uses high-performance capacitive displacement sensors from Lion Precision during the assembly procedure.

The sensors, capable of resolving position to less than 10 nanometers, are used during the mounting of over 10,000 thin glass mirrors into the telescope’s “lens.” Each mirror is about the size of a sheet of paper and only four times thicker – they are very delicate. Achieving the required optical specifications for the telescope requires that each of the mirrors be mounted into position with better than 1 µm of accuracy. The mirrors must be able to hold this positional and angular accuracy during launch and deployment in space.

Orbital X-ray telescope technology for high-performance capacitive displacement sensors.

Orbital X-ray telescope technology for high-performance capacitive displacement sensors.

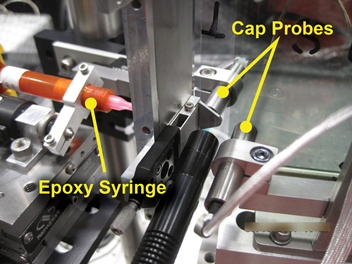

A specially designed machine holds the mirrors precisely in place while they are bonded to mounting tabs with ultraviolet cured epoxy. The system uses Lion Precision Elite Series capacitive sensors to monitor changes in the mirror position during the epoxy injection. The machine adjusts the epoxy pressure to precisely move the mirrors into the proper position.

Previously, laser displacement sensors were used but were eventually abandoned because of insufficient resolution, size-related mounting difficulty, and generation of too much heat causing thermal expansion of the components during the delicate operation. The capacitive sensors are less expensive, small enough to easily mount, and generate virtually no heat during operation.

The process has been documented with photos and charts in the Lion Precision website Tehcnical Library at:

http://www.lionprecision.com/tech-library/appnotes/cap-0022-NASAxRayTelescope.html, or

http://bit.ly/GOqU3J

In 1958, Lion Precision was the first company to provide capacitive displacement sensors to industry. The company has expanded its product offering to include eddy-current displacement sensors and some application specific sensors for the machine tool, packaging and PCB industries. The company is focused on assisting users in sensor implementation by providing expert guidance and optimized systems including custom designs.