Interview conducted by Olivia FrostFeb 14 2023

Interview conducted by Olivia FrostFeb 14 2023In this interview, Vanessa Germann, the Global Marketing Manager at LMI Technologies, talks to AZoSensors about 3D smart sensor technology.

Can you explain what LMI does and the company´s background in developing sensors?

LMI Technologies brings 40+ years of leadership experience in the global machine vision industry. The company started out with a focus on developing 3D sensors for the wood industry and quickly expanded to meet the demands of scanning, measurement and inspection for factory automation applications across a number of industries such as automotive, road and rail, rubber and tire, and then later packaging, consumer electronics, semiconductor manufacturing, and the list keeps growing.

Today we are primarily an exporter of 3D sensor products and services into all major manufacturing centers around the world covering the Americas, EMEA, and APAC regions. Our company’s ongoing mission is to help customers use 3D vision technologies to improve their factory production, especially in applications where 2D technology is unable to meet their scanning and inspection needs (e.g. for the accurate measurement of shape/geometry of manufactured parts and assemblies).

What is 3D smart sensor technology?

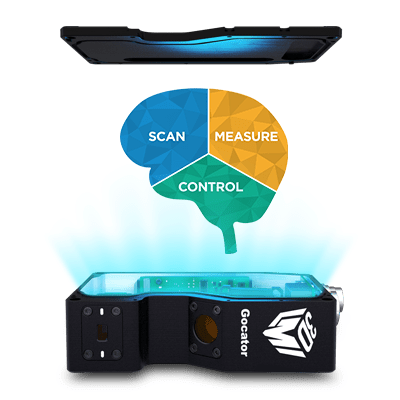

Unlike 2D smart cameras or 3D cameras, a 3D sensor is a pre-calibrated device that can perform the full sequence of image to laser extraction to the generation of calibrated 3D point clouds onboard.

This means the 3D sensor has a fixed arrangement of the camera, laser, and optics that are factory pre-calibrated to output measurement units on power up. The 3D point clouds generated by the sensor are transferred to a PC to carry out inspection applications.

So basically 3D Smart Sensors are able to measure out-of-the-box with integrated measurement tools and deliver an all-in-one functionality through a common web browser delivering fluid, responsive user interfaces for rapid setup, visualization, and monitoring. Additionally, these sensors offer multi-sensor-networking for maximum scan coverage, including 360º scanning and inspection.

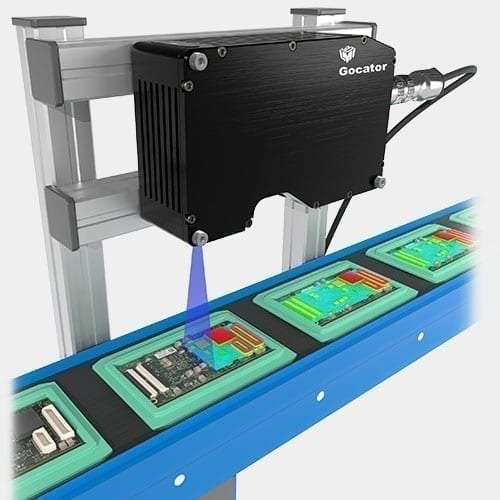

Image Credit: LMI Technologies Inc.

Can you explain what LMI does and the company’s background in developing sensors?

LMI Technologies brings 40+ years of leadership experience in the global machine vision industry. The company started out with a focus on developing 3D sensors for the wood industry and quickly expanded to meet the demands of scanning, measurement, and inspection for factory automation applications across a number of industries such as automotive, road and rail, rubber, and tire, and then later packaging, consumer electronics, semiconductor manufacturing, and the list keeps growing.

Today we are primarily an exporter of 3D sensor products and services into all major manufacturing centers around the world, covering the Americas, EMEA, and APAC regions. Our company’s ongoing mission is to help customers use 3D vision technologies to improve their factory production, especially in applications where 2D technology is unable to meet their scanning and inspection needs (e.g. for the accurate measurement of shape/geometry of manufactured parts and assemblies).

What are LMI’s flagship sensor product lines?

LMI Technologies’ flagship product is Gocator, the world’s leading 3D smart sensor for factory automation, inline quality inspection, material optimization, and smart 3D robot vision in industrial inline applications. This rugged, high-performance lineup of smart 3D laser, structured light, and line confocal sensors delivers 3D scanning, measurement, and control all in a single package.

Can you describe some of the individual products in these lines and their applications?

The Gocator 2300 series smart 3D laser line profilers are the workhorse sensors of our product catalog. They are designed for the demanding industrial conditions of the factory floor. The feature of Gocator’s signature simple and flexible design enables factories to reduce costs and maximize profitability by improving efficiencies in product validation.

Another example of the versatility of the Gocator product line is LMI’s Gocator 5500 Series of Smart 3D Line Confocal Sensors, which adds patented line confocal imaging technology to the Gocator® family. These line confocal sensors deliver high-speed, wide-coverage line scanning with simultaneous generation of 3D topography, 3D tomography, and 2D intensity data. This allows Gocator® 5500s to scan practically any material type––including multi-layered, transparent/translucent, curved edge, shiny/specular, high-contrast textured, mixed, and many more––with submicron precision, and at a level of quality and speed that outperforms competing confocal technologies. These sensors are by far the most advanced sensors in LMI’s portfolio.

Hardware products are really just the beginning of the story. Software is (and always has been) one of LMI’s main product offerings and a key differentiator from competing sensor manufacturers who do not offer their own measurement software––and therefore, the customer must invest in and integrate 3rd party solutions.

FactorySmart® AI Solutions is an end-to-end customer engagement that includes edge hardware running AI algorithms that support factory communication with PLCs and logic controllers and a user interface for production staff. LMI's support services utilize cloud connectivity to monitor system performance, health data and provide software updates.

What is multi-sensor networking, and what are its uses?

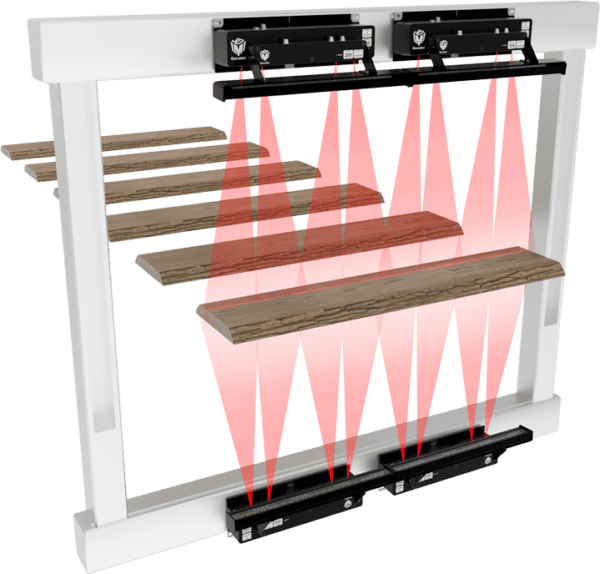

The data handling of many sensors that scan a single target, called multi-sensor networking, is an important capability to support large object applications. Many sensors are required when the target object is larger than what a single sensor is able to scan, or when multiple views are required to capture key features of an object.

Multi-sensor networking capability is one of the most powerful differentiators of Gocator 3D smart sensors over every other competing product on the market. The ease and accuracy of this built-in process, from alignment to power and scan synchronization to the ability to scan 360º of an object and generate highly accurate stitched 3D point clouds of the complete surface area (such as cylindrical components) is a game-changer for vision customers.

Image Credit: LMI Technologies Inc.

What are the advantages of a 360⁰ view or multiple views of a target object, and how does Gocator achieve these things?

Gocator® software supports 3D mesh data generation for advanced shape measurement and inspection of multi-view 360º surface scans. Mesh data consists of “stitched” scans from multiple sensors. The result is a 360º Mesh of the object that can be used for measurement with other surface tools.

These sensors have many applications, from producing high-resolution profiles to monitoring 2-meter-wide fields of view.

Image Credit: LMI Technologies Inc.

What are the advantages of clients configuring sensor layout and aligning to a common coordinate system?

All sensors in a network have to be aligned in order to relate measurements from a sensor to an absolute position on the object. To do this, alignment transformations are required to convert from sensor coordinates to a common coordinate system (i.e., world coordinates). The fact that this capability is built-in to the Gocator architecture and not something that has to be done on a separate device or 3rd party software is of huge benefit to the customer.

What advantages does Gocator technology have over competitor systems?

LMI’s leading smart sensor design architecture includes an easy-to-use web-based interface, on-sensor measurement tools, data processing, I/O connectivity, native multi-sensor networking, and more. The result is the most cost-efficient 3D sensor solution on the market.

Why Choose Gocator? The Smart Sensor Advantage

What are the advances of the new Gocator® 2600 Series sensors?

That they are IIoT-ready with a web-based user interface accessible through any browser. The 4K imager generates 4200 data points per profile and up to 2.5 µm X resolution. Higher point density means the finest features are captured for measurement and inspection. The sensors scan, measure, and control in a single device. The sensor head leverages an onboard custom controller to generate 3D scan data, apply surface measurements, and execute pass/fail control decisions––with no external controller required. This results in a lower overall package price and comes with full 3D surface and profile generation out-of-the-box, with free software upgrades for the life of the product.

How does LMI ensure clients have the correct sensor for the job?

LMI’s globally recognized sensor product lines include Gocator All-In-One 3D Smart Sensors (laser, snapshot, line confocal) and chroma+scan 3D Log and Board Scanners. We now also offer full-service AI-based solutions for deep-learning-driven industrial inspection.

LMI sensors generate both 2D intensity and 3D shape data of manufactured products used for multi-dimensional measurement and quality inspection. These versatile sensors come in a variety of speeds, resolutions, and fields of view so users can choose the best solution for their application needs.

Where can readers find more information?

We invite readers to find more information at the following links:

For introductory Gocator 3D Smart Sensor information: https://lmi3d.com/brand/gocator-3d-smart-sensors/

For videos: https://lmi3d.com/videos/

For brochures, factsheets, case studies, and more: https://lmi3d.com/discovery_center/

About Vanessa Germann

Vanessa Germann holds a Bachelor's Degree in German and English Language and Literature. She joined LMI in 2017 as a Marketing Specialist and took over the EMEA regional marketing in 2019 as Regional Marketing Manager. Since 2023 she is now in charge of LMI's overall Marketing strategy as Global Marketing Manager. Before joining LMI, she was a PR consultant for aerospace topics and also worked in Public Relations for the Hong Kong Government Representation for Germany, Austria, Switzerland, and Eastern Europe.

About LMI Technologies

As the global leader in 3D scanning and inspection, LMI Technologies works to advance quality and productivity with 3D sensor technology. Our award-winning, FactorySmart® laser, snapshot, and line confocal sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies. Unlike contact-based measurement or 2D vision, our non-contact solutions add 3D shape information that is critical to achieving 100% quality control. We also offer turnkey AI-based solutions to deploy the power of deep-learning-driven visual inspection into your industrial production processes.

To learn more about how LMI’s inspection solutions can benefit your business, we invite you to contact us at [email protected] or visit us at www.lmi3d.com to explore the possibilities of smart 3D technology.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.