NewTek customizes its LVDT Linear Position Sensors and LVRT Inductive Half Bridge Sensors with mounting features such as blocks or flanges to fit into the existing footprint of steam turbines, eliminating the need for turbine operators to update or replace costly legacy equipment including mounting equipment, brackets, and mechanical indicators.

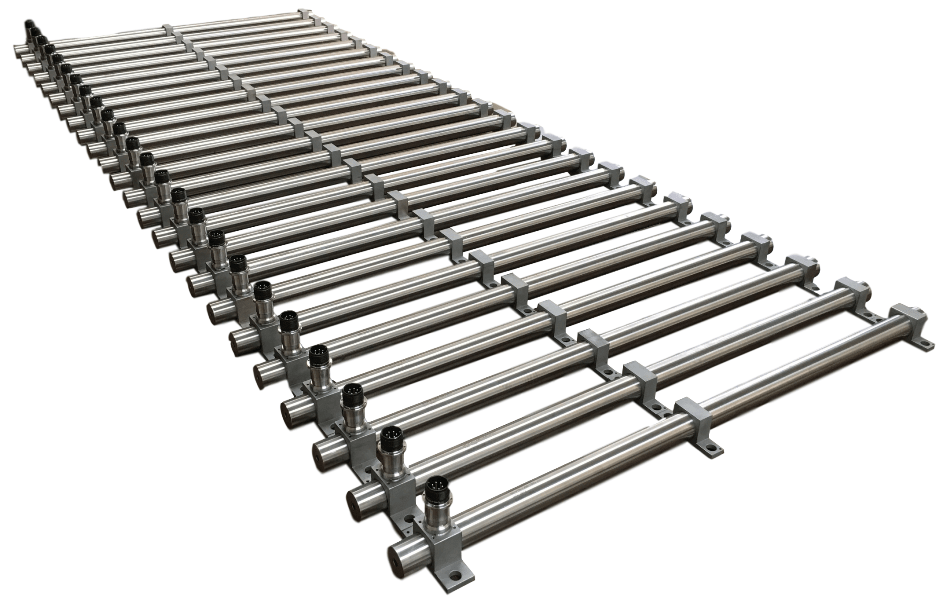

Shown are LVRTs customized with stainless steel mounting feet with pre-machined holes for bolting to the mounting brackets of a steam turbine. The mounting feet are welded to the stainless steel LVRT housing to ensure they never separate or come loose under harsh environments and vibration.

Shown are LVRTs customized with stainless steel mounting feet with pre-machined holes for bolting to the mounting brackets of a steam turbine. The mounting feet are welded to the stainless steel LVRT housing to ensure they never separate or come loose under harsh environments and vibration.

LVDTs and 3-wire LVRTs are installed in various locations on the steam turbine to track turbine vibration for health monitoring and maintenance prediction and provide feedback on the open/close status of steam inlets and governor valves.

As the LVDTs and LVRTs are often exposed to high vibrations on the steam turbines, NewTek welds the stainless-steel blocks and flanges to the sensors so footing remains rugged. In addition, some linear position sensors are customized with threated connectors for long-term performance in the high-vibration environments of the turbine. Other mounting blocks or methods might become loose over time and compromise measurement quality.

AC-operated LVDTs and LVRTs are the only technologies that can survive steam exposure with high temperatures. For example, NewTek’s High-Temperature HATR-750 Series withstand the extreme temperatures of turbines up to 400 °F (204 °C) with excellent linearity, high sensitivity and infinite resolution. The linear position sensors are also very resilient to harsh vibration typically association with turbine operation. NewTek signal conditioning provides the digital output from the AC-operated sensors in a variety of outputs to meet various protocols including Modbus, CAN Bus, RS-485 and more.

NewTek also customizes mounting feet for sensors used in subsea applications for structural monitoring.

Source: https://www.newteksensors.com/