Oct 11 2022Reviewed by Alex Smith

In the near future, people who have minimal hand function can have an easy way of manipulating devices such as wheelchairs, computers, and smartphones, by wearing a smart mouthguard that interprets complex bite patterns precisely and rapidly into instructions to regulate electronic devices.

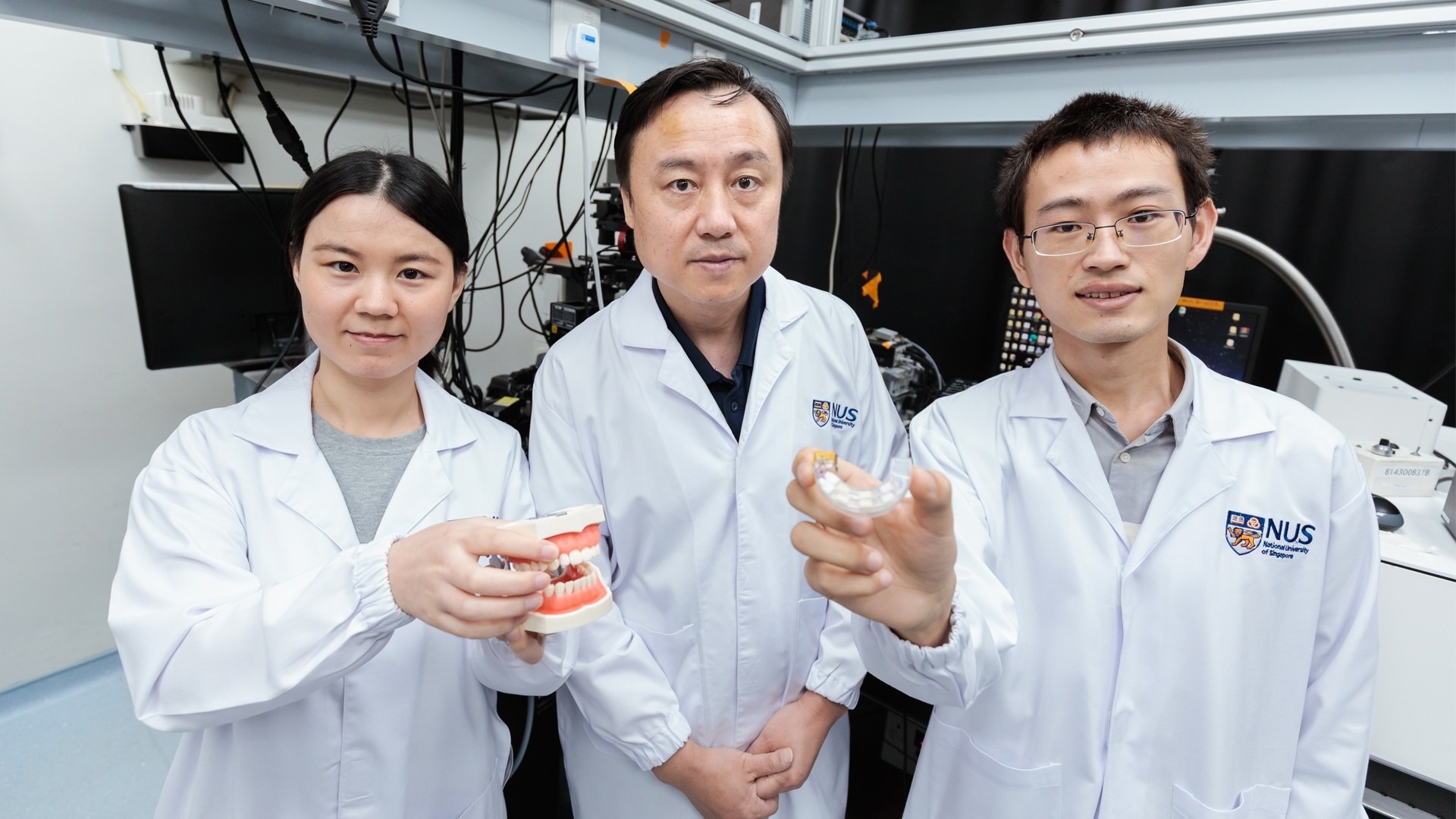

An NUS research team led by Prof Liu Xiaogang (center) has created a revolutionary mouthguard that uses bite force to operate electronic devices such as computers, smartphones, and even wheelchairs with high accuracy. Image Credit: NUS

An NUS research team led by Prof Liu Xiaogang (center) has created a revolutionary mouthguard that uses bite force to operate electronic devices such as computers, smartphones, and even wheelchairs with high accuracy. Image Credit: NUS

This bite-controlled optoelectronic platform is the first of its kind and was invented by a research group directed by Professor Liu Xiaogang from the Department of Chemistry at the National University of Singapore (NUS) Faculty of Science, along with collaborators from Tsinghua University.

Several assistive technologies like eye tracking, voice recognition, and brain-computer interfaces have been designed in the past to help people—particularly those with neurological disorders or limited dexterity—control electronic gadgets. However, these technologies have limitations related to cost, control accuracy, environmental interference, and maintenance.

To provide a favorable substitute to current assistive technologies, Prof. Liu and his team have fruitfully engineered and illustrated a smart mouthguard comprising integrated pressure sensors to recognize occlusal patterns. These patterns are interpreted into data inputs with 98% precision and can be used to regulate smartphones, computers, and wheelchairs.

The team’s technological innovation has been reported in the October 10th, 2022, issue of the journal Nature Electronics.

In addition to supporting human-computer interaction, the interactive mouthguard can also be used for healthcare devices such as smart electronic skin, medical assistance, and dental diagnosis.

Limitations of Current Assistive Technologies

Assistive technologies help to boost autonomy and independence for individuals with disabilities. Regrettably, such technologies also have major downsides. For example, voice recognition necessitates a large operating memory and needs to work in a low-noise setting, while eye tracking necessitates a camera to be placed in front of the user and is susceptible to fatigue.

Although brain–computer interfaces have been upgraded significantly in the last few years, this technology is invasive and necessitates bulky wired instruments.

Bite force, frequently used as a factor to measure chewing function, is a favorable area that is not properly understood or exploited. As dental occlusion offers high-precision control and entails marginal skill, the NUS team formulated a new idea for assistive technology by employing exclusive patterns of occlusal contacts.

Translating Bite Patterns into Useful Data for Device Control

The NUS team first engineered a sensor containing a series of contact pads having diverse colored phosphors—these are materials that produce light in reaction to pressure. The array of contact pads is positioned inside a flexible mouthguard.

Biting results in the mechanical deformation of the contact pads, which then produce light in various colors and intensities. This can be quantified and processed using machine learning algorithms. The data gathered is then used for high-accuracy remote control and working of numerous electronic gadgets, such as wheelchairs, computers, and smartphones.

Weighing around 7 gm, the new mouthguard needs minimal training experience when compared to current assistive technologies.

Our bite-controlled optoelectronic system is capable of translating complex bite patterns into data inputs with 98% accuracy. We have also demonstrated that our novel sensors can distinguish mechanical deformations, including strain, compression, and bending, making them applicable to multifunctional mechanical sensing applications, such as miniaturized force sensing, flexible electronics, artificial skin, and dental diagnosis.

Professor Liu Xiaogang, Department of Chemistry, Faculty of Science, National University of Singapore

Each smart mouthguard at present costs S$100 to create in the laboratory, and the researchers anticipate that the cost would be considerably low in mass production. Although the present prototype is engineered for well-aligned teeth, a mouthguard with an uneven arrangement of phosphor-infused pads could be created for users with various tooth patterns or for people who wear dentures.

Next Steps

The researchers have filed a patent for this ground-breaking technology, and they are seeking opportunities to authenticate their device in a medical setting, such as nursing homes or care centers. Simultaneously, the NUS team is also seeking ways to improve its technology, such as quicker data processing and training.

Journal Reference:

Hou, B., et al. (2022) An interactive mouthguard based on mechanoluminescence-powered optical fibre sensors for bite-controlled device operation. Nature Electronics. doi.org/10.1038/s41928-022-00841-8.

Source: https://nus.edu.sg