Nov 20 2012

OMRON Corporation today announced the development of its new NX series I/O safety system. The products below will be exhibited at SPS/IPC/DRIVES 2012 to be held in Germany from November 27 to 29 and SEMICON Japan 2012 to be held from December 5 to 7*1.

- NX series I/O units (Scheduled for release in spring 2013)

- NX series safety controllers (Scheduled for release in spring 2013)

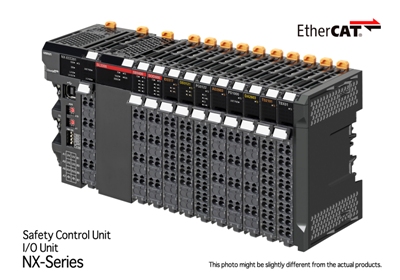

OMRON's new NX Series integrated I/O safety system (Photo: Business Wire)

OMRON's new NX Series integrated I/O safety system (Photo: Business Wire)

The products are all fully compatible with the Sysmac automation platform*1 launched in July 2011. This new style of EtherCAT-compatible modular I/O system enables sequence, motion, and safety control to be integrated into machine control systems.

The new NX series I/O system enables simple and flexible design for high-speed, high-precision motion control and safety control in an integrated engineering environment when used in conjunction with the NJ series machine automation controller and the automation software Sysmac Studio. This contributes to productivity improvements and assurance of safety conforming to international standards.

Machine designers are now required to design globally competitive production machinery for global manufacturing sites with systems appropriate for flexible production methods and quantities, and short lead times.

Under such circumstances, the designers must design sequence, motion, and safety control at the same time while increasing their knowledge of machine design in order to conform to international safety standards, and this results in a heavy workload. Moreover, functionality and flexibility are required even in the safety control domain, and a system to ensure safety while maintaining productivity is expected. Omron's new NX series I/O system was designed to meet these needs.

The NX series I/O system was developed based on the Sysmac concept:

- "One Connection" enables the NJ series machine automation controller to be connected with safety control units and standard I/O units in one single EtherCAT system. This contributes to simpler system construction and greater work efficiency.

- "One Software" enables integrated programming for control systems including sequence, motion, and safety control with the Sysmac Studio automation engineering environment. This standardizes design assets and increases reusability, thereby significantly improving machine control design efficiency.

*1 The NX series will be exhibited in the EtherCAT Technology Group's booth.

Features

- 1. Safety control now integrated into the Sysmac "One Connection" concept

A single EtherCAT slave that adopts easily expandable modular design allows easy connection with all devices: standard I/O devices and high-speed I/O devices for sequence control as well as safety controllers and safety I/O devices for safety control. This simplifies flexible system design to meet optional user specifications, and simple wiring improves work efficiency.

- 2. Engineering safety also integrated into the Sysmac "One Software" concept

Previously, safety control was designed separately from sequence and motion control through the design cycles including design, verification, debugging, test operation, startup, improvement, and addition of functions. Now the automation software Sysmac Studio enables the same operability and GUI*3 as those of machine control design to be used for safety control design to build a system, which simplifies the design process.

Modular structure can be built up for each program when designing safety control. The modularized safety programs can be reused for other designs, and the amount of device verification work required for validation can be reduced.

*3. GUI: Graphical User Interface. User interface that enables intuitive operation with graphics and pointing devices such as a mouse.

- 3. IEC 61131-3 programming language for safety controller

IEC 61131-3 programming language (function block diagrams), which is recommended by PLCopen, is adopted for the safety controller and provides a design environment that can be used as standard all over the world. This drastically reduces the time required for designers to master design procedures and programming rules, and simplifies the sharing of programs globally.

- 4. Space-saving modular unit

The NX series adopts a modular structure. The width of the standard I/O unit is 12 mm or 24 mm (safety CPU unit: 30 mm, safety I/O unit: 12 mm). The required width of the new unit is reduced by approximately 70% compared to Omron's previous remote I/Os*4 for EtherCAT with terminal blocks, which can reduce the size of the system and the control panel. The detachable screwless clamp terminal block contributes to reduced wiring work.

*4. Omron's GX series DI/DO: 16 points, AI: 4 points

- 5. Ultra-high-speed, high-precision control through synchronous I/O refreshing

In the previous remote I/O system, I/O refreshing*5 in the CPU of the NJ series machine controller and the master and slave communications units for remote I/O control was performed at different times, so high-speed and high-precision control in fixed time cycles was difficult due to the time difference of I/O refreshing. The distributed clock that synchronizes time among devices connected via EtherCAT ensures complete synchronization of I/O refresh cycles between the CPU of the NJ series machine controller and the NX series I/O units, which facilitates the high-speed and high-precision control required for motion applications.

*5. I/O refreshing: Packages of external data from sensors/switches that are directly connected to the PLC or the basic I/O unit are exchanged with data in the PLC internal I/O Memory.

Source: http://www.omron.com