Hydraulic and thermal-magnetic circuit breakers serve as essential safeguards against electrical faults.

In scenarios where extreme weather conditions and harsh surroundings are possible, the magnetic hydraulic circuit breaker offers distinct advantages in circuit protection that surpass those of thermal circuit breakers.

Core Design Differences

Thermal Circuit Breakers

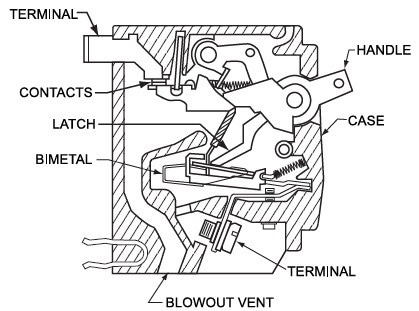

During the regular operation of thermal circuit breakers, the circuit is designed to open when a predetermined calibration temperature is reached due to the deflection of a thermal sensing element (e.g. bi-metal).

The rise in temperature in the sensing element is primarily caused by load current 12 R heating, while it also integrates heating or cooling effects from external sources.

The size, configuration, physical shape, and electrical resistivity of the thermal element determine the current capacity of the circuit breaker.

A heater coil is sometimes placed adjacent to the thermal element. It is electrically connected in series to enhance the self-heating of the thermal trip element, particularly for ratings below five amperes.

The most common thermal element is a “sandwich” comprising two or three different metals, where the low expansion side can be made of invar (a nickel steel alloy), the center can be made of copper for low resistivity or nickel for high resistivity, and the metals used in the high expansion side vary considerably.

Figure 1. Diagram of a standard thermal circuit breaker. Image Credit: Sensata Technologies, Inc.

Hydraulic Magnetic Circuit Breakers

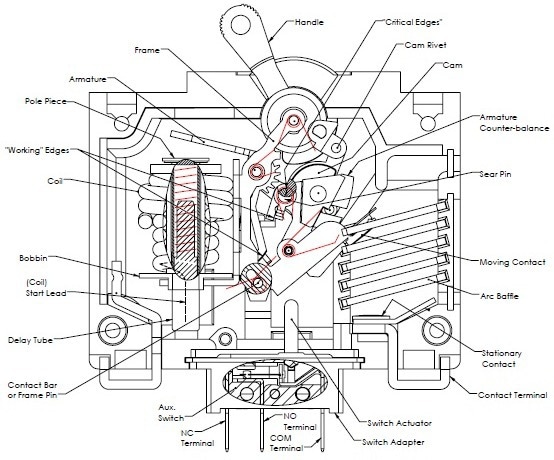

Hydraulic magnetic circuit breakers operate on a different principle than other circuit breakers. The magnetic time-delay circuit breaker functions using the solenoid principle, where a movable core, held by a spring in a tube and damped with fluid, can be moved by the magnetic field of a series coil.

Under normal operating conditions, where the current flowing through the unit remains at or below the rated current, the mechanism will not trip, and the contacts will remain closed.

If the current exceeds 100 percent but remains below 125 percent of the rated current, the magnetic flux generated by the coil will be sufficient to move the delay core against the spring, causing it to come to rest against the pole piece.

This movement of the core increases the flux in the magnetic circuit, causing the armature to rotate from its normal position. As the armature rotates, it trips a pin that unlatches the collapsible link of the mechanism, opening the contacts.

The delay tube is filled with silicone fluid, which controls the speed at which the delay core moves within the delay tube assembly. Using fluids of different viscosities can result in obtaining different delay curves.

The magnetic circuit should produce sufficient flux to trip the unit without the delay core changing position when high current surges occur in an electrical circuit.

To protect UL appliances, such as those listed previously, protector delay curves should be applied that provide an instant trip at surges of 600 percent or more.

Focusing on the Impact of Ambient Temperature

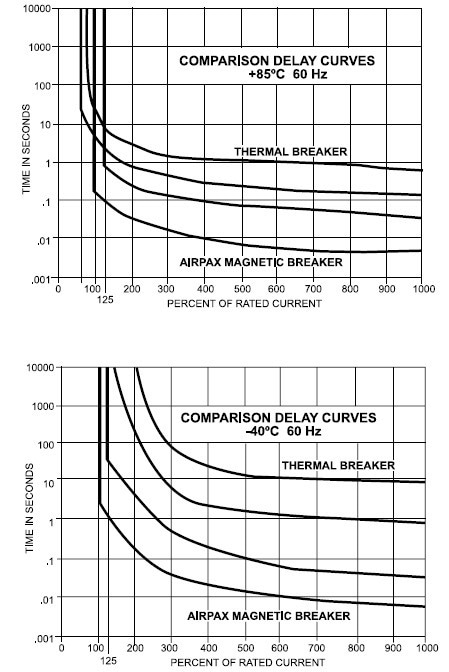

Thermal circuit breakers rely on the temperature rise in their sensing element to trigger their activation. Consequently, they are naturally impacted by variations in ambient temperature.

Although temperature-compensated circuit breakers have been developed to address external temperature changes by incorporating a thermally responsive element, the fundamental issue remains.

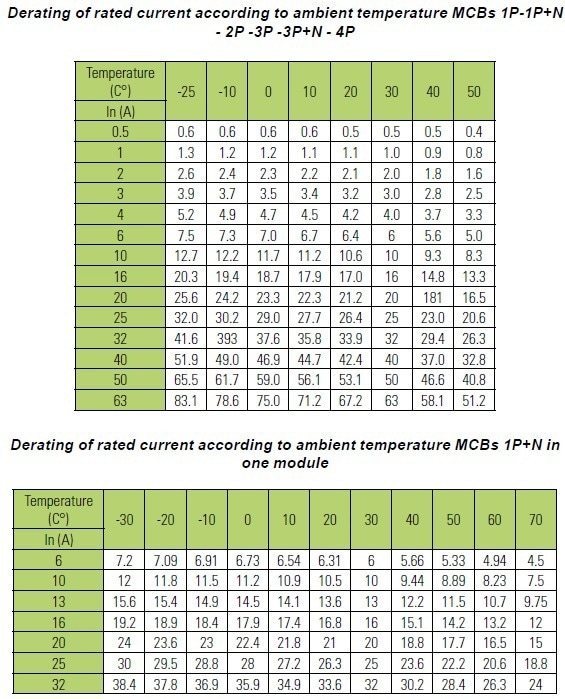

Choosing the appropriate thermal breaker is a complicated process that goes beyond matching the breaker rating with the wire rating. Other considerations, such as the ambient operating temperature, allowable voltage drop, and heat sinking provided must be taken into account.

The difficulty of selecting the correct breaker is compounded when the most critical factor, ambient temperature, is unknown.

Equipment manufacturers distribute their products globally from various manufacturing locations, without knowledge of the environmental conditions in which their equipment will operate.Therefore, a circuit breaker rated at 10 A may trip at 7 A in high-temperature conditions or as late as 13 A in colder environments.

Figure 2. Diagram of a Magnetic Hydraulic circuit breaker. Image Credit: Sensata Technologies, Inc.

Thermal circuit breakers are de-rated based on the ambient temperature. In high-temperature environments, these breakers are typically oversized to prevent nuisance tripping, which poses a risk from an electrical protection standpoint.

On the other hand, in colder environments, the circuit breaker may be underrated to address slower trip times, but this undermines the primary purpose of electrical protection.

Conversely, hydraulic magnetic circuit breakers do not face the same challenges and maintain a consistent rating and performance across a wide temperature range from -40 °C to 85 °C.

Figure 3. Image Credit: Sensata Technologies, Inc.

Figure 4. Image Credit: Sensata Technologies, Inc.

The hydraulic magnetic circuit breaker, located within the circuit breaker, provides several options for achieving a precise current rating.

Additional components, such as a steel shunt plate fixed to the top of the coil or an inertial wheel attached to the armature, can be added to dampen the electromagnetic flux associated with inrush current, preventing nuisance tripping.

Incorporating these options is particularly beneficial for circuits with high start-up inrush currents.

These components can include integrated aux switches, relay trips, and voltage coils that can be remotely tripped if necessary, while thermal breakers require an additional half-pole module.

While each device type has its applications, hydraulic magnetic circuit breakers are the preferred power control component for equipment that may be shipped globally because they offer a temperature-stable solution.

This makes them the most effective option for telecommunications, data and servers, transportation and rail, defense, marine, power generation, and other industries.

This information has been sourced, reviewed and adapted from materials provided by Sensata Technologies, Inc.

For more information on this source, please visit Sensata Technologies, Inc.