Professional coffee machines require accurate water pressure measurements in the boiler and brewing loops. The pressure instruments must withstand the high temperatures and stresses generated during cleaning and have specialized wetted parts.

To ensure safe food production, pressure instrumentation must also be certified for drinking water and food applications. To ensure the espresso's quality, the pump outlet's brewing pressure must remain stable.

To achieve this stability, espresso machine manufacturers often install an over-pressure valve (OPV) at the pump outlet side. However, adjusting an OPV may require dismantling the machine, as it is not always easily accessible.

In response to consumer demands for ease of use, modern coffee machines now feature a single button for regulating brew pressure, which can be easily accessed from outside the machine.

This feature typically involves substituting the OPV with a proportional valve and a pressure transducer installed behind the valve. Professional coffee and vending machines may be either tabletop or free-standing models.

Image Credit: Sensata Technologies, Inc.

Working Principle

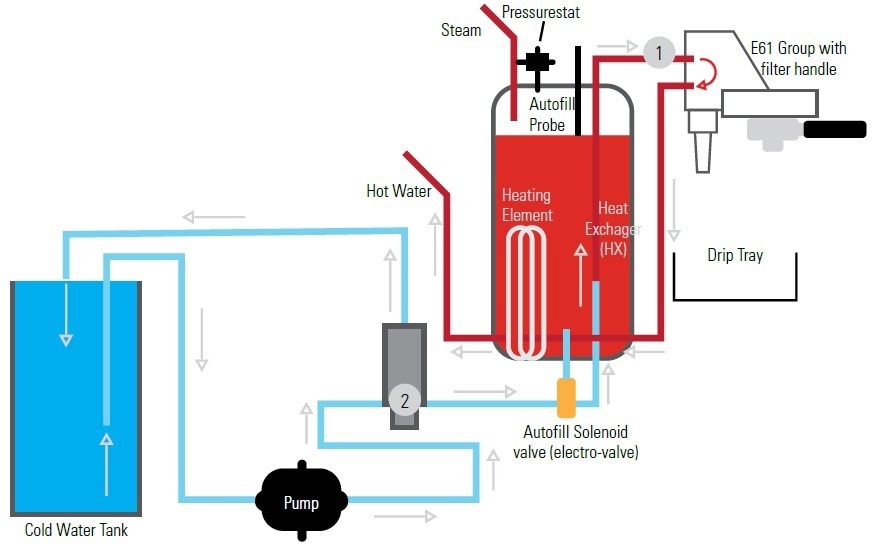

- The machine can receive water through connected plumbing or manual filling of the tank

- Water is heated up to 95 °C in the boiler

- The boiler pressure regulates the temperature of the water

- A pressure switch is located in the boiler loop

- In the brewing loop, the pressure transducer and proportional valve work in tandem

- The SSR controls the heating elements of the steam, hot water, and brew boilers

Solution

The pressure transducer can monitor brewing pressure, typically at 9 bar, by being connected to either the cold-water piping at the pump outlet or the hot-water piping nearer to the end product behind the boiler.

The sensor is linked to a power source. Modification in the system's pressure will lead to an alteration in the output signal, specifically voltage.

Recommended Products

Table 1. Source: Sensata Technologies, Inc.

| Reference on Diagram |

Product |

Features |

Function |

Brand |

| 1 |

|

116CP/117CP

126CP/127CP* |

- Operating pressure range: 0-60 to 0-230 PSI (0-4 to 0-16 Bar)

- Supply voltage: 5 VDC ratiometric or 8-30VDC voltage regulated

- Output: 0-3.5 VDC, 0-4.5 VDC, or 4-20 mA

- Pressure port: Quick Connect, G1/4, G3/8

- Electrical connection: RAST 2.5

|

Monitoring of the pump outlet pressure / heated water supply pressure |

Sensata Technologies |

| 2 |

|

60CP/70CP

81CP

100CP

35CP |

- Operating pressure range: 0-15 to 0-750 PSI (0-1 to 0-50 Bar)

- Supply voltage: 5 VDC ratiometric or 8-30 VDC voltage regulated

- Output: 0-4.5 VDC or 4-20 mA

- Pressure port: 1/8"" NPTF-2A male, 1/4"" NPTF-2A male, G1/8, G3/8

- Drinking water-certified options are available

|

Monitoring of the pump outlet pressure / heated water supply pressure |

Sensata Technologies |

*Drinking water certified

Diagram

Image Credit: Sensata Technologies, Inc.

This information has been sourced, reviewed and adapted from materials provided by Sensata Technologies, Inc.

For more information on this source, please visit Sensata Technologies, Inc.