Photonics technology is crucial in contemporary manufacturing processes, revolutionizing several industries by enabling efficient, more precise, and faster production. Photonics comprises manipulating, generating, and detecting light and its properties; its incorporation into manufacturing processes has resulted in significant advancements. This article looks at how photonics technology is useful in manufacturing and how it impacts different sectors.

Photonics technology is applicable in many aspects of manufacturing, including sensing, communication, imaging, and material processing. When it comes to imaging, photonics-based cameras, as well as sensors, are largely used for inspection, quality control, and metrology.

Defect Detection

Advanced imaging techniques and high-resolution cameras allow manufacturers to measure dimensions, detect defects, and ensure product quality throughout different stages of production. These imaging systems quickly find scratches, flaws, or imperfections that could be invisible to the human eye, improving product reliability.

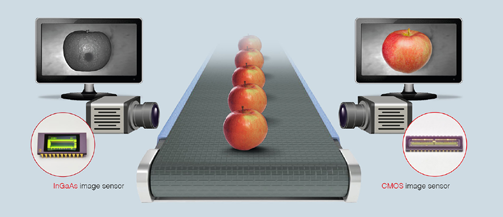

Different high-speed imaging devices can be arranged strategically on the conveyor belt to maximize food sorting inspection. Fruits traveling down the conveyor belt can be scanned using CMOS and InGaAs cameras.

The InGaAs camera uses infrared technology to show defects starting to form under the skin that humans are unable to see. The CMOS camera can show visible defects. All detected defects will help filter out produce that is not viable for stores.

Image Credit: Hamamatsu Photonics Europe

Optical sensors are found in many modern cars that create elegant interiors, modular lighting, and interactive displays. These applications are seamlessly transforming the driving experience, offering comfort as well as safety. This technology is also essential for advancing LiDAR (light detection and ranging) technology.

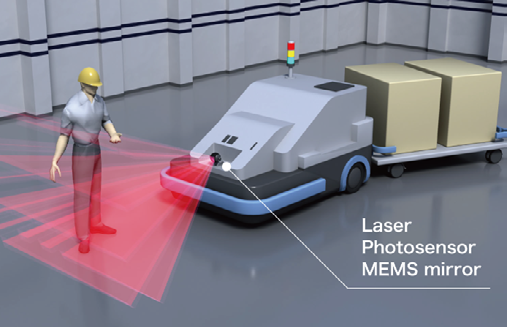

LiDAR provides a wealth of applications with precise measurements, monitoring, and detection that range from autonomous driving to assisting manufacturers with automating security or the quality control process.

Rapidly revolutionizing the industry, LiDAR systems also use laser light to map surroundings, measure distances, and detect objects accurately. They are widely used in robotics (e.g., moving objects), automated guided vehicles (AGVs), and smart manufacturing systems for real-time feedback and control. Integrating LiDAR sensors into manufacturing processes enables companies to optimize workflows, enhance safety, and achieve higher productivity.

AGV (Automatic Guided Vehicle) using LiDAR-based technology. Image Credit: Hamamatsu Photonics Europe

The Rise of Laser Technology

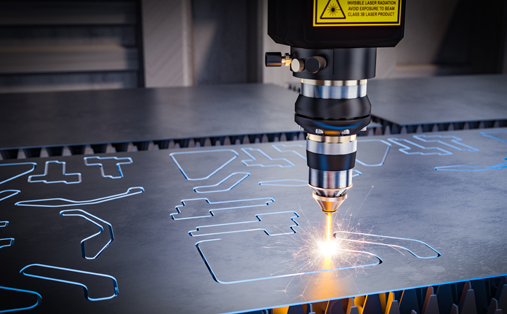

Laser technology also brings significant advancements to material processing. Laser-based systems are used extensively for cutting, marking, welding, and surface treatment of many materials.

Lasers offer a high-energy, focused beam of light that can precisely and accurately process materials, leading to enhanced productivity and improved product quality. For example, laser cutting machines offer high-speed, contactless cutting of plastics, metals, and textiles, allowing for intricate and complex designs with minimal material wastage.

Laser welding provides a quick, efficient, and non-contact method for joining materials, while laser marking provides permanent and high-resolution branding and product labeling.

3D printing uses lasers and other light sources to selectively melt or cure materials layer by layer, creating complex 3D objects.

Photonics-based 3D printing offers the ability to produce highly customized parts, fast prototyping, and even the manufacturing of difficult or even traditionally impossible to produce complex geometries. This technology has revolutionized several industries, including automotive, aerospace, and healthcare, by reducing production time, enabling cost-effective small-batch production, and fostering design innovation.

Laser machinery for metal cutting. Image Credit: Hamamatsu Photonics Europe

The Era of Communication

Finally, efficient data transfer and communication are vital to manufacturing environments. Fiber-optic communication systems are widely utilized for high-speed, long-distance data transmission between control systems, machines, and remote monitoring stations.

Fiber-optic cables, comprised of thin strands of plastic or glass, enable light signal transmissions carrying sizable amounts of data with the support of integrated transmitters and receivers. For example, transmitter and receiver photo ICs support various transmission speeds over long distances at high speeds. This means secure, reliable communications with minimized latency and electromagnetic interference.

The capability to transmit data quickly and without loss makes fiber optics a significant component of modern manufacturing infrastructure. New developments in quantum optical communication can offer secure and encrypted communication through the use of low-noise, high-efficiency, and high-quality single photon emitters and detectors.

In conclusion, photonics technology has profoundly impacted manufacturing processes across many industries. Hamamatsu Photonics’ extensive portfolio of components, systems, and modules provides innovative, high-quality, high-performance solutions to the manufacturing industry. It continues to utilize expertise and 70 years of knowledge to move photonics technology forward, support greater transformations in manufacturing processes, and lead the way to reduced costs, increased productivity, and improved product performance.

This information has been sourced, reviewed and adapted from materials provided by Hamamatsu Photonics Europe.

For more information on this source, please visit Hamamatsu Photonics Europe.