In this article, the fundamentals of heat flux measurement are discussed.

The Importance of Position and Time for Heat Flux Sensors

Image Credit: Hukseflux Thermal Sensors B.V.

Heat flux sensors take measurements at a particular location; however, this location may not be representative of the characteristic of interest. Therefore, if possible, it is preferable to employ a relatively large sensor and consider the use of multiple sensors. However, larger sensors can be less sensitive, hence the use of a small sensor is sometimes preferrable.

Due to the large time constants of many thermal processes, instantaneous heat flux measurements can be misleading. Therefore, it is important to take an average of measurements over a prolonged period.

Optical Properties

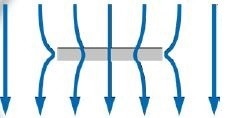

Image Credit: Hukseflux Thermal Sensors B.V.

In cases where radiation is being measured, it is important to consider the color of the surface and, if necessary, paint the sensor surface or use gold and black stickers to measure convective and radiative heart flux separately. Shiny metallic surfaces reflect both infra-red and visible radiation, and while paints have different colors in the visible range, they are usually “black” absorbers and emitters in the far-infra-red.

Absolute Temperature

Image Credit: Hukseflux Thermal Sensors B.V.

Sensors are calibrated at room temperature TCAL, and the typical temperature dependence is 0.15 % K-1. When working at extreme temperatures (T) it is important to consider temperature dependence. Typically, this is a linear correction calculated as T – TCAL. Self-calibrating sensors may compensate for temperature dependence.

Edge Effects

Image Credit: Hukseflux Thermal Sensors B.V.

A heat flux sensor locally distorts the heat flow pattern, particularly around the edges, as the heat may preferentially travel through the sensor rather than through the surrounding material.

A passive guard, a non-sensitive part around the sensor, is essential to avoid errors due to edge effects. Micro effects can play a larger role on a smaller scale, which is discussed further below.

Thermal Contact Sensor to Heat Sink

Image Credit: Hukseflux Thermal Sensors B.V.

A small layer of air can produce a major contribution to the thermal resistance. Therefore, it is essential to ensure good thermal contact between the sensor and the environment or heat sink.

Minimize air gaps by utilizing double-sided tapes, welded connections, and graphite sheets. Employ power strips to effectively seal any remaining gaps.

Sensor Thermal Resistance

Image Credit: Hukseflux Thermal Sensors B.V.

A heat flux sensor distorts the local heat flux. To minimize this effect, a sensor with the lowest possible thermal resistance should be employed.

Noise

Image Credit: Hukseflux Thermal Sensors B.V.

Signals from thermopiles are small DC voltages in the microvolt range. As a result, they can be easily distorted. Grounding and shielding must be employed to prevent interference from external sources. Well-insulated signal wires with no ground loops and protection against humidity ingress are crucial.

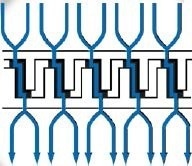

Micro Effects – Thermal Conductivity Dependence

Image Credit: Hukseflux Thermal Sensors B.V.

If a thermopile sensor is directly exposed to the environment, there is a risk of so-called micro effects. On a micro-scale (that of the thermopile grid), the local heat flux becomes distorted and preferentially travels through the thermopile. As a result, the sensor sensitivity changes as a function of the thermal conductivity of the environment. In these cases, the calibration is no longer valid.

A thermal spreader, such as a metal cover, can be introduced as a countermeasure, as the heat flux first meets the metal plate, maintaining the thermal environment of the thermopile, so that the sensitivity of the sensor does not depend on the environment, and is essentially constant.

This information has been sourced, reviewed and adapted from materials provided by Hukseflux Thermal Sensors B.V.

If you would like to have more information about heat flux measurements and heat flux sensors, please contact Hukseflux.