MTI capacitance sensors are designed to measure the thickness of insulating materials such as glass, sapphire, many plastics and even semi-insulating semiconductors material such as gallium arsenide (GaAs) and silicon nitride (Si3N4) with thickness <10 mm and uniform dielectric constant.

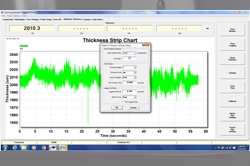

MTI’s new capacitance amplifier is capable of converting the gap capacitance directly to a digital target thickness. This direct conversion technique eliminates errors that traditional analog amplifiers have due to analog filtering, range extension, linearization, and the summing of channels to achieve thickness or step measurements. Calibration can be performed in less than a minute with a sample of the material that has known thickness.

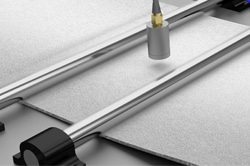

MTI offers a comprehensive non-conductive material measuring system. The company’s complete package includes MTI special dielectric probes, a dieletric fixture, a capacitance amplifier (up to 4 channels), and a smart software package with integrated computing capability that eliminates all of the guess work out of what used to be a complex measurement.

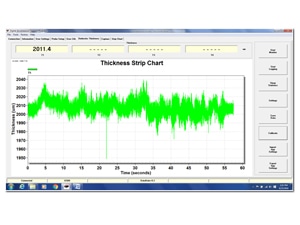

The typical feature quadrature encoder input provides probe positional data simultaneously with its thickness signal. Capacitance thickness amplifiers used with quadrature encoders synchronize displacement measurements to the probe position to offer accurate surface profiles of different target types. Sample rate, filter frequency response, linearization, and probe range can all be digitally controlled with the Accumeasure D series.

This guarantees the most accurate data capture, lossless processing and the freedom from purchasing additional acquisition hardware.

Key Features

The main features of the MTI capacitance sensors are as follows:

- Capable of measuring both thickness and displacement of glass, Silicon, Sapphire, SiC, GaAs, and other high bulk resisvity materials

- Accuracy of up to 1 µm

- Integrated calibration software

- Measures translucent, opaque, or clear materials

- Full digital linearization of the gap response

- Interface with NI LabVIEW™

- Lossless 24 bit processing

- Modifiable output data rate

- Digitally controlled range extension, filtering and signal averaging

- Analog output

- For specific applications, tailor-made probes can be manufactured by MTI

- Supplementary acquisition hardware is not required

Complete Solution for Measuring Non-Conductive Materials

Digital Accumeasure D Amplifier

Software with built-in computing capability

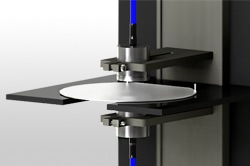

_securely.jpg)

Holds selected probe(s) securely

_and_the_Target_Material.jpg)

Fixture to Hold Probe(s) and the Target Material and choose from different probes that suits your requirement

| Probes |

Product # |

Min.Range to Target at x1 Range |

Normal Range at x1 |

Max. Range Extension |

E |

D |

L |

| µm |

mils |

µm |

mils |

mm |

inch |

mm |

inch |

mm |

inch |

| ASP-250M-ILA |

8100-2013-410 |

12.5 |

0.49 |

250 |

9.8 |

4x |

3.53 |

0.139 |

5.59 |

0.220 |

11.79 |

0.464 |

| ASP-300M-CTA |

8100-0013-000 |

15 |

0.59 |

300 |

11.8 |

4x |

3.81 |

0.150 |

12.00 |

0.472 |

36.00 |

1.400 |

| ASP-400M-ILA |

8100-2012-410 |

20 |

0.78 |

400 |

15.7 |

4x |

4.29 |

0.169 |

13.59 |

0.535 |

10.84 |

0.427 |

| ASP-2500M-CTA |

8100-0009-000 |

125 |

4.9 |

2500 |

98.5 |

3x |

11.25 |

0.443 |

25.00 |

0.984 |

63.50 |

2.500 |

| ASP-5000M-CTA |

8100-0010-000 |

250 |

9.8 |

5000 |

197 |

2x |

15.93 |

0.627 |

38.00 |

0.149 |

63.50 |

2.500 |

Applications

Laser sensors or other non-contact measurement sensors will not work with glass, plastic, sapphire materials because of shiny clear surfaces, foam/cell bubbles that ricochet the laser beam or laser cross talk through the material.

The non-conductive nature of the material causes traditional capacitance gauges and eddy current gages not to function.

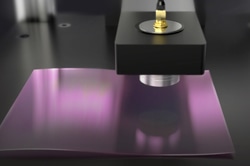

MTI's capacitance probes produce an electric field that passes via the insulating material, and the dielectric constant of the insulating material conducts that field. For the capacitive system to be able to measure thickness, it has to account for various dielectric constants by going through a calibration with the material to be analyzed. The calibration will remain consistent if the dielectric constant of the material does not change.

Built-in Computing Capability

Measuring Plastic Thickness

Thickness of Foam

Sapphire Wafer Inspection

Less than a Minute Calibration for Non-conductive Measurement

Accumeasure D - Calibrating for non-conductive measurement