Dyniscopressure Transducer

Image Credit: Dynisco

Transducer Definition

Question: How can a transducer be defined?

Answer: A transducer is a device with the capacity to convert one kind of energy to another. This conversion can be to/from electrical, electro-mechanical, electromagnetic, photonic, photovoltaic, or any other form of energy.

Example: Via electromagnetic conversion, a guitar amplifier takes the vibrations of the guitar’s strings and converts this to a sound frequency that is heard through the speaker.

Transducer Technology

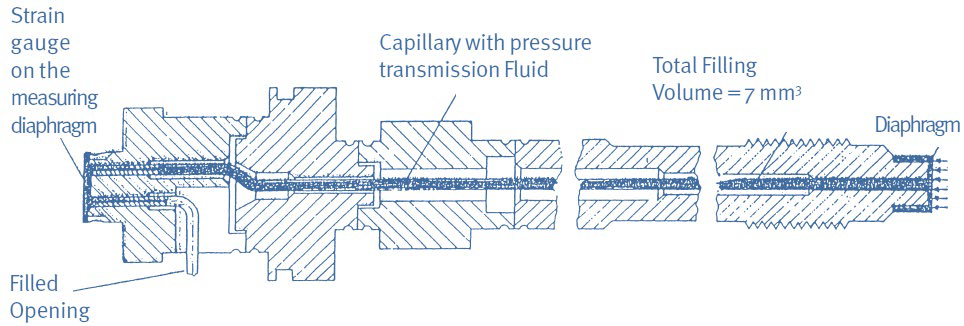

Question: How does a pressure transducer function?

Answer: By integrating the foil strain gauge, a filled capillary and diaphragms to acquire a controlled pressure change which is electronically converted to signal output, that is then scaled to a distinct pressure range.

Image Credit: Dynisco

Signal Outputs

Available signal outputs for Dynisco sensors:

- Millivolt (one thousandth of a volt) symbol = mV

- Milliamps (one thousandth of an ampere) symbol = mA

- Volt (the measure of electric potential) symbol = V

Available ranges for the various signal outputs:

- Millivolt = 2 mV/V, 3 mV/V, 3.33 mV/V (other ranges available upon request)

- Milliamps = 4-20 mA, 4-20 mA with HART (pressure ranges can be assigned)

- Volt = 0-5 V, 1-6 V, 0-10 V, 1-11 V (other ranges available upon request)

Benefits of Pressure Transducers

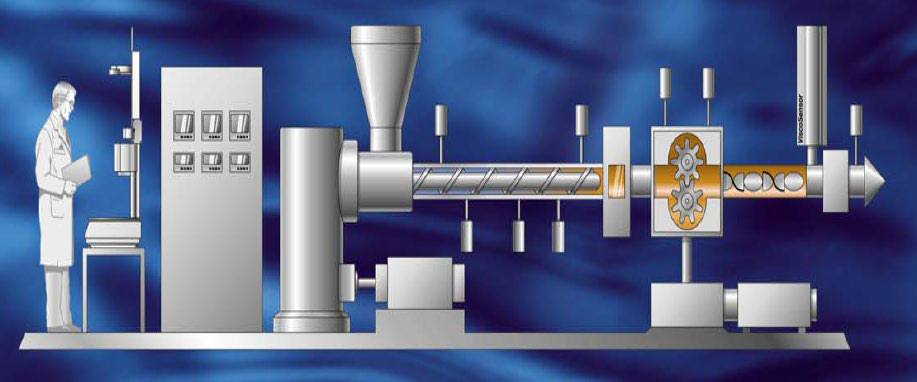

In Plastic Extrusion, pressure fluctuations at the die entrance could be the result of either an actual rate fluctuation coming from the extruder or a variation in temperature impacting viscosity.

- Pressure fluctuations are generally controlled using gear pumps

- Gear pumps can be made to have pressure transducer ports

- Transducers will allow the operator to make changes to process variables based on pressure readings identified via signal output to instrumentation.

- Instrumentation can be programmed to stop the extruder if a pressure condition occurs that may compromise the equipment.

- Pressure signals to instrumentation allow management of screen changers that filter out particle contaminants in the melt.

- Instruments will monitor and log pressure variations at the die head, offering the operator the appropriate data to improve the process

When melt temperature is stable, pressure variations are often a result of:

- Barrel Temperature change

- Inconsistent screw speed

- Operating conditions

- Poor screw design

- Variations in Feed Stock

Dyniscopressure transducers and Instruments enable detection of these conditions

Image Credit: Dynisco

Image Credit: Dynisco

Pressure Measurement Benefits

- Happier customers

- Increased productivity

- Increased Profits

- Increased Safety

- Less Down

- Longer life

- Quality products

- Reduced waste

- Reduced costs

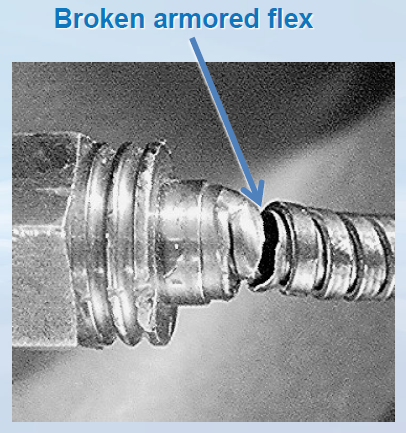

Transducer Tip

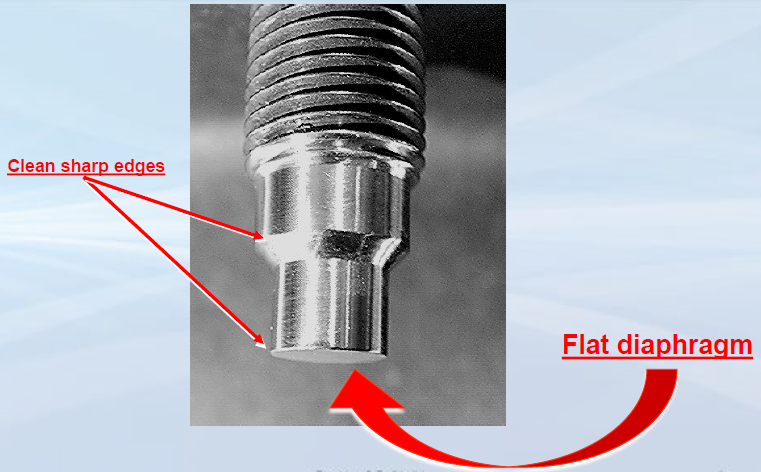

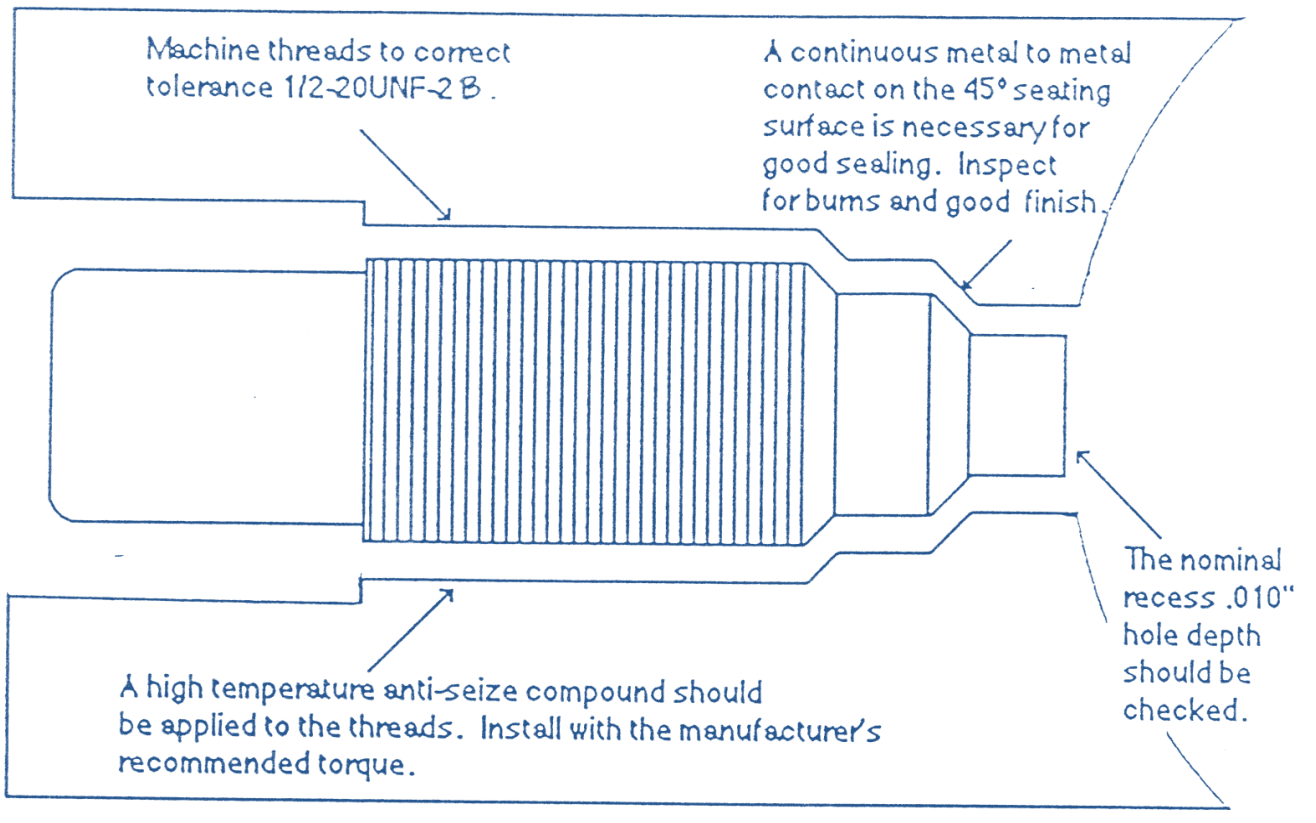

Dynisco’s pioneering cap diaphragm is a machined 45-degree sealing surface that meets industry standard ½-20 threads composed of one-piece stem construction in most models.

Image Credit: Dynisco

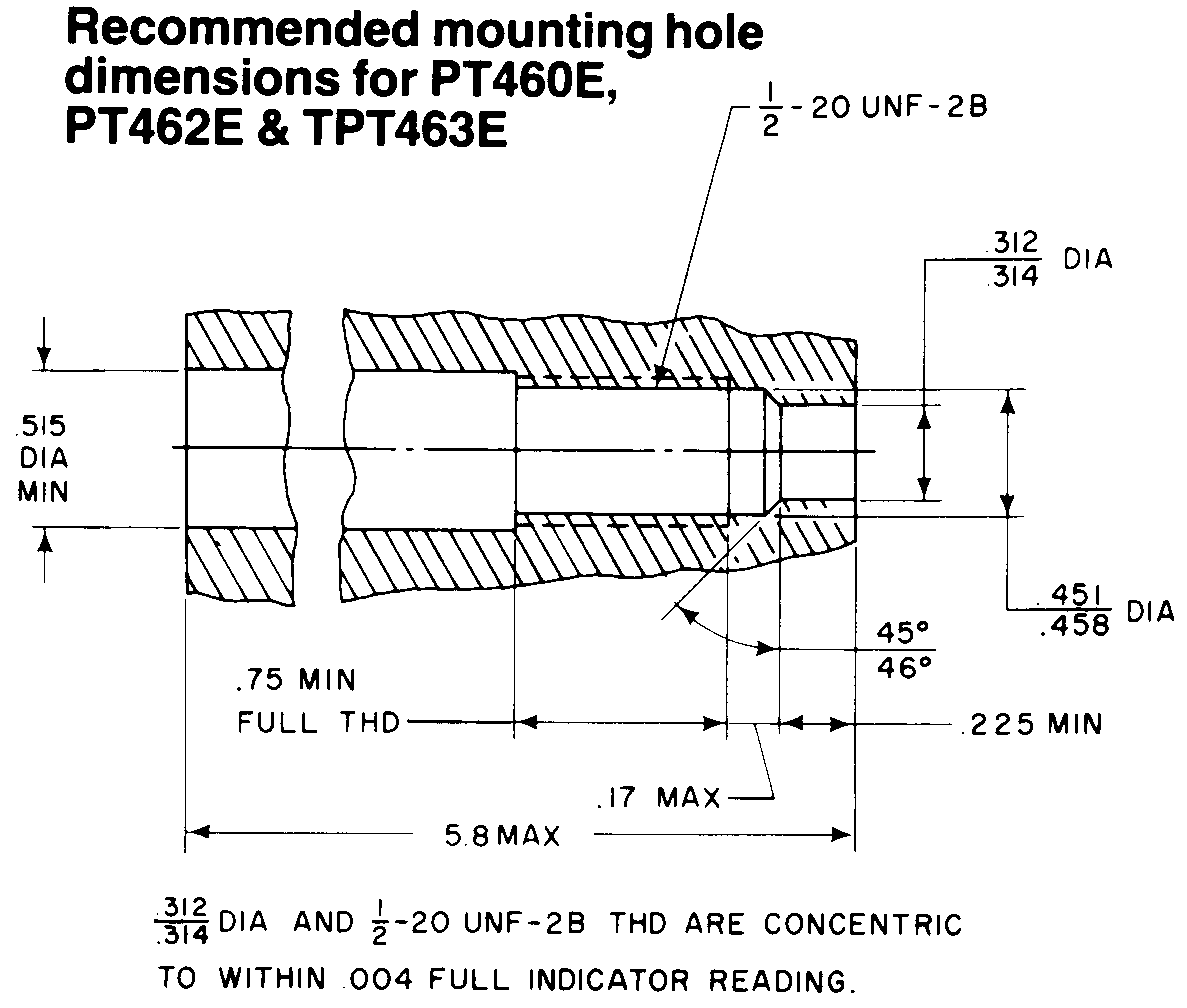

Standard Threads

The threads are the industry standard of 1/2-20 UNF as improper dimensions will result in thread galling and material leakage. It is crucial to ensure appropriate hole dimensions using the Gauge Plug included in the Dynisco Cleaning Tool Kit: part number 200100.

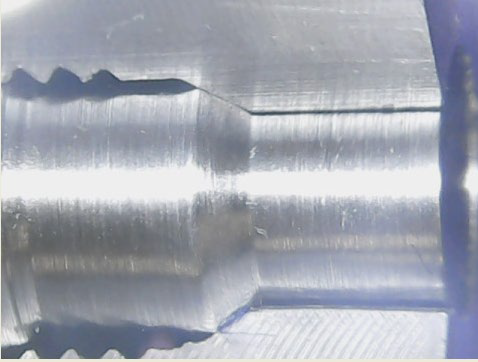

Transducer Tip

Image Credit: Dynisco

This is the way a transducer tip should look when it’s new.

Image Credit: Dynisco

Transducer Location

- Before screen changer

- Before melt pump

- After melt pump

- In the dies

Image Credit: Dynisco

Location Benefits

Appropriate position of the transducer avoids unnecessary pressure build-up while ensuring adequate melt feed to pump. As well as ensuring adequate pump pressure to die and adequate pressure for the product, it ensures safety.

Location

Too close to the feed zone can result in damage from unplasticized pellets. Mounting too shallow in the hole leads to excessive deterioration of the material and freeze-off.

Mounting too deep can cause damage to the tip resulting in measurement errors.

Repeated hole cleaning can result in holes being ‘too deep,’ as well as possible tip damage. Therefore, make use of spacers.

Dry Location

Standard transducers are not water-tight. Dynisco circuitry can withstand extrusion plant environments but will not function when wet. Therefore, it is crucial to specify water-tight transducers when wet operation is unavoidable.

Transducer Mounting

Mounting holes are important as they cannot be eccentric, too small, or too large.

Image Credit: Dynisco

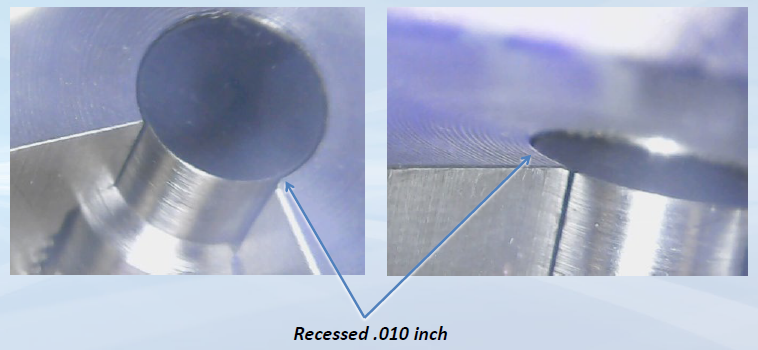

Mounting Depth

- Usually recessed around 0.010” this depth will help avoid any unnecessary diaphragm wear and prolong the life of the pressure transducer: Kit number to make the holes is PN 200925

- If the hole is already too deep, use stackable 45 degrees 0.025” copper spacers (PN 633511): Aluminum also available

Image Credit: Dynisco

Image Credit: Dynisco

Image Credit: Dynisco

Mounting Conditions

When mounting transducers, always use a high temperature anti-seize compound. It is important to also use proper mounting torque:

- 100-200 inch-pounds (8-16 ft lbs.) may vary on transducer type

- 500 inch-pounds Maximum (250 for push rod)

- Rule of thumb is finger tight plus 1/4 turn

Transducer Mounting Techniques

For the machining of a new hole, use Dynisco’s Machining Tool Kit, #200925. The following considerations when mounting torque upon installation should also be made:

- Too little causes leaking

- Too much results in seizing and damage to the transducer

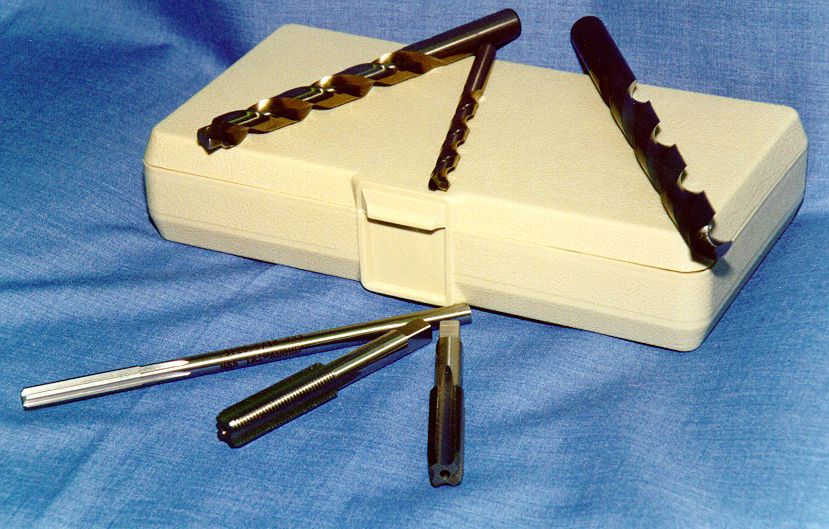

Dynisco½ 20 UNF Machine Tool Kit (200925)

Image Credit: Dynisco

Removal of the Pressure Transducer

- Always remove the transducer while the equipment is hot and clean away any polymer residue from the tip by using a cotton rag.

- Do not use the wire wheel on the bench grinder!

- Always clean the hole before reinstalling the transducer

- Use the Dynisco Cleaning Kit # 200100

Dynisco½ 20 UNF Cleaning Tool Kit (200100)

Image Credit: Dynisco

Cleaning Tool Kit Contents

- Bottoming tap - For thread cleaning

- Guide Sleeve/Cleaning Drill - For hole cleaning

- Bluing – Checks hole cleanliness and size

- Gauge Plug - Insures proper fit

- Instructions

Cleaning the Mounting Hole

Always remove the transducer prior to cleaning the barrel with abrasives, cleaning compounds, or a wire brush. Remove the transducer while the barrel is still hot and wipe the transducer tip clean. Remember to return and clean the hole with the cleaning drill/guide sleeve

Clean Mounting Hole

Image Credit: Dynisco

Mounting Hole Review

Dynisco cleaning tool kit (p/n 200100) makes the job easy, but remember to remove the transducers when cleaning the barrel, remove them when they’re still hot and extract any plastic build-up in the hole.

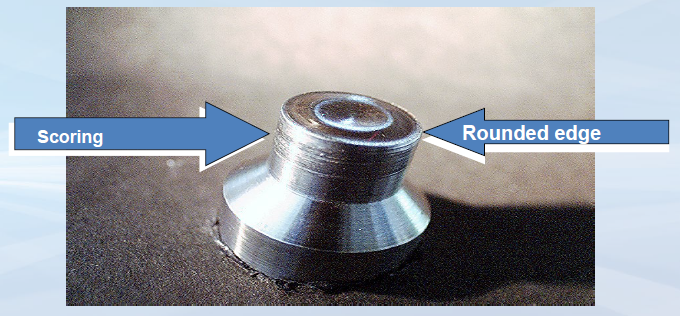

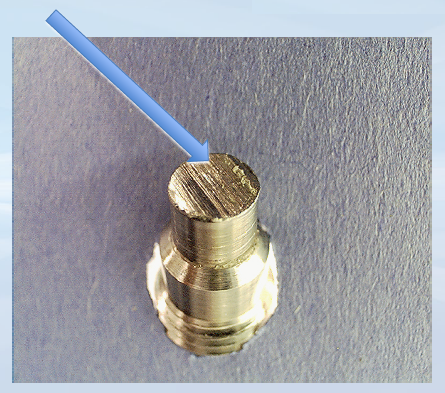

Mounting Hole Problems

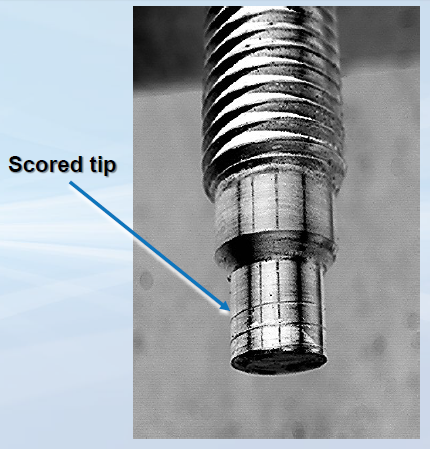

- Problem: Damaged tip – Reason: Improper hole

- Problem: Galled threads – Reason: No anti-seize used

- Problem: No response – Reason: Over-pressured

Mounting Hole to Small

Image Credit: Dynisco

Image Credit: Dynisco

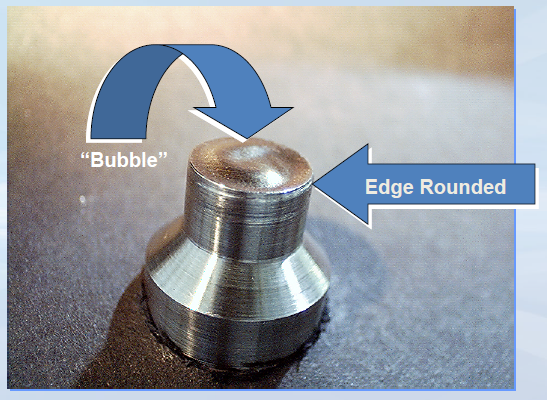

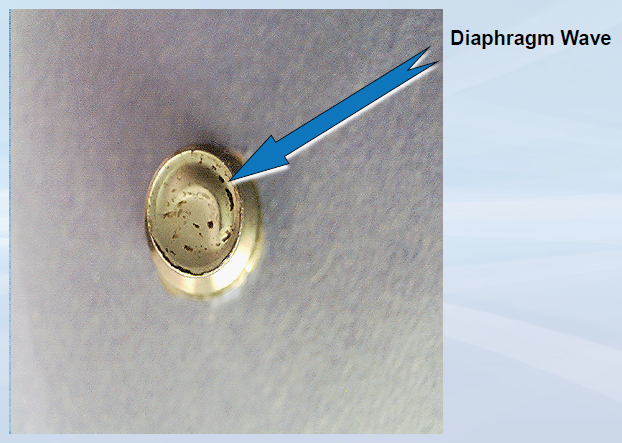

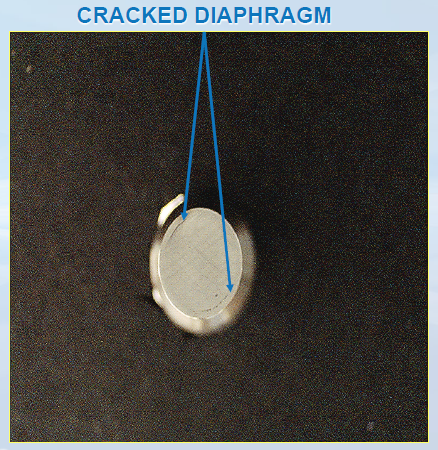

Diaphragm Damage

Image Credit: Dynisco

Image Credit: Dynisco

Image Credit: Dynisco

Image Credit: Dynisco

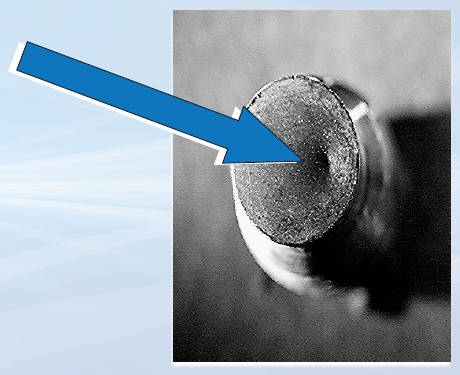

Tip Damage

Image Credit: Dynisco

Transducer Damage

Image Credit: Dynisco

Selecting Pressure

Transducers operate best at midrange:

- Transducers can handle 1.5 times overpressure without damage.

- Overpressure can occur when cold material inhibits the flow.

- Verify that the operation of the transducer is within the rated range.

- Pay special attention to the pressure range when extruding varying materials.

- Like people, over-pressured transducers cannot carry out their job properly.

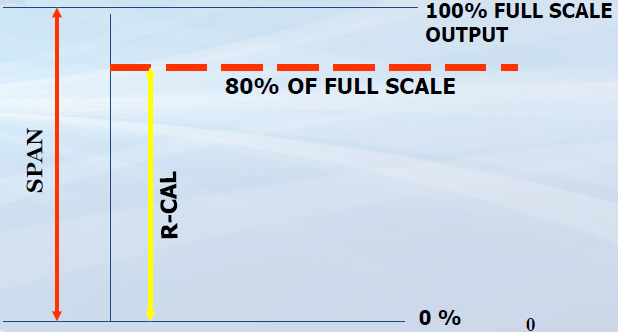

Calibrating a Transducer

- When? When it’s up to operating temperature and at zero pressure.

- How often? When your ISO9000 standards dictate, or if the zero appears to have shifted.

It’s simple: Dynisco transducers have a built-in 80% R-Cal, and indicators that utilize R-Cal to calibrate the span.

Shunt Calibration ‘R-CAL’

All Dynisco Melt Pressure Transducers incorporate a built-in 80% of full scale ‘R’-CAL. This is achieved using an internal resistor to electrically unbalance the bridge rather than strain-induced via applied pressure. ‘R’-Cal supplies a rapid and accurate method of transducer-to-instrumentation calibration.

Image Credit: Dynisco

How can Dynisco Help YOU?

- Stabilize your process

- Operate more efficiently

- Increase profit

- Increase consistency and quality

- Help your profitability

Helpful Literature

Dynisco has published a number of documents to assist customers with application support. Please contact a Dynisco Rep for further details.

Image Credit: Dynisco

Conclusion

- Dynisco manufactures the most rugged and reliable transducers for the extrusion industry

- Dynisco is an ISO9001 company

- Appropriate care and handling will provide many years of service

- Dynisco has a Repair Program to fix all damaged transducers

This information has been sourced, reviewed and adapted from materials provided by Dynisco.

For more information on this source, please visit Dynisco.