There is a growing need for plastics because these products are increasingly being used as an alternative for metals and other types of materials in the electrical, electronic, automotive, and construction sectors.

Generally, plastic converters and plastic producers will preserve plastic pellets in narrow and tall silos, which present a challenge to all radar and ultrasonic beam spread technologies ABB laser level transmitters have narrow beams, which allow them to be effectively used in this sector with scores of installations made over the last decade.

Figure 1. Storage silos for plastic pellets. Image Credit: ABB Measurement & Analytics

Applications

Plastic manufacturers generally constitute large chemical and petrochemical firms that manufacture and deliver raw plastic material, largely in the form of pellets, to the remaining supply chain.

Such firms value live inventory reporting and automation solutions, and they have utilized level measurement for blending or storage silos. Manufacturers of plastic products also utilize level measurements in day bins or storage silos for inventory management.

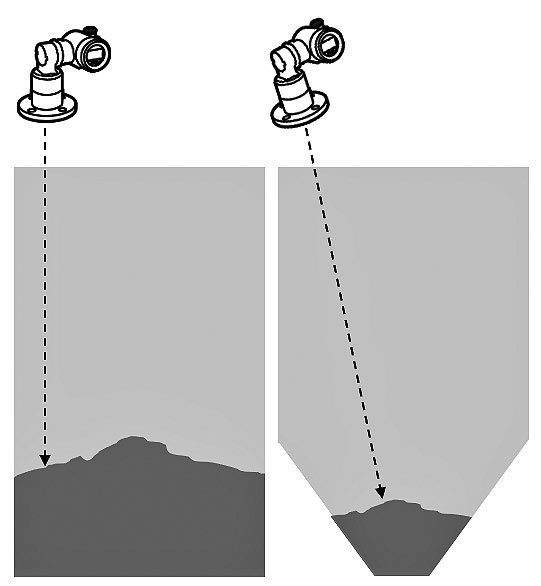

Tall and narrow storage silos pose a challenge to any beam spread technology. Laser level has been successfully used in this application because of its narrow beam and potential to quantify right down to the base of the silo, as shown in Figure 2.

Figure 2. Narrow beam emitted by the LLT100. Image Credit: ABB Measurement & Analytics

Laser beams are narrow (less than 0.3° divergence) and produce a tiny spot on the surface, usually less than 30 cm even at extended ranges. A standard installation is demonstrated in the following sections.

Using a swivel flange, the LT100 laser level transmitter is placed on a spool piece to accurately aim at the base of the silo. A dust tube is also employed for better protection. For plastic applications, a metal mounting flange or plate should be used and the same should be correctly grounded to the silo to help disperse static build-up.

Another major benefit of using lasers in such applications is that silos of day bins are generally the same as illustrated below. Laser levels are different from other technologies and only had to be configured for the initial silo.

This configuration can subsequently be used for all the remaining silos, rendering installation and commissioning faster, easier, and cheaper.

Figure 3. Typical installation. Image Credit: ABB Measurement & Analytics

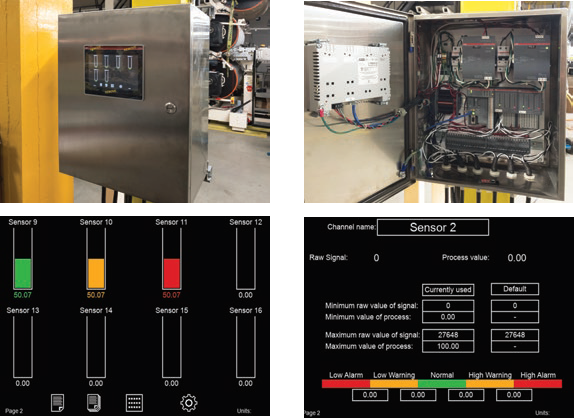

Complete Turnkey Solution

Apart from its LLT100 laser level solution, ABB also provides a complete turnkey solution with a customized user interface, PLC control panel, I/Os, displays, etc. As illustrated in Figure 4, this kind of solution is usually delivered to silo manufacturers as part of a full-solution package during the expansion or construction of plants.

Figure 4. Turnkey solution. Image Credit: ABB Measurement & Analytics

Figure 5. Day bins. Image Credit: ABB Measurement & Analytics

Benefits

The LLT100 laser level transmitters provide several advantages for these applications:

- Non-contact technology to enhance reliability; plastic pellets will not adhere to the device and break moving parts, which generally result in repetitive maintenance as is the case for contact technologies

- Works with even low dielectric constant materials

- Powerful laser beam reflection from plastics when compared to radar waves

- Small divergence and narrow beam directly focus at the base of a conical vessel

- The usual environment is not dusty, and hence does not present any problem to laser beam

- Can be deployed quite close to the wall and is not affected by vessel shape or internal structures

Conclusion

For LLT100 laser level transmitters, plastics manufacturing and processing offer one of the most fascinating markets with many opportunities across the world.

Tall and narrow storage silos employed in this sector are highly challenging for radar and ultrasonic spread technologies but are ideal environments for lasers because of their narrow beams and potential to fully measure to the bottom of the silos.

With scores of installations made over the last 10 years, ABB laser level transmitters have enjoyed remarkable success in this application.

This information has been sourced, reviewed and adapted from materials provided by ABB Measurement & Analytics.

For more information on this source, please visit ABB Measurement & Analytics.