Spectrophotometry has been used for quantitative analyses in physics, chemistry, biochemistry, and chemical engineering for decades. This well-established analytical method employs a light source and sensor to measure the intensity of light passing through a water sample in a cell with a known path length.

Ultraviolet and visible (UV-VIS) light sources are most commonly used. Substances in the water sample absorb or transmit light over a specific wavelength range, with Beer’s Law stating that the measured absorbance of substances in the water sample will be directly proportional to their concentration.

Significant advances in spectrophotometry have been made over the past 10 years, allowing the method to be used reliably and accurately in real time. One of the primary benefits of continuous spectrophotometric measurement is the capacity to relate the concentration of the absorbing substances to real-time absorbance measurements.

A range of natural and synthetic organic substances absorb light in the UV-VIS wavelength spectrum, as well as nitrate and nitrite. Suspended matter in water will also scatter and reflect light, but it is possible to compensate for this in-measurement.

A diverse array of industries now uses this online technology to continuously measure water and wastewater quality parameters, including:

- Chemical oxygen demand (COD)

- Biochemical oxygen demand (BOD)

- Dissolved organic carbon (DOC)

- Total organic carbon (TOC)

- Nitrates (NO3-) and nitrites (NO2-)

- And many other chemicals

The method’s real-time capabilities are extremely beneficial to applications dependent on parameters such as BOD and COD that are conventionally tested in a laboratory, or parameters like TOC that are costly to perform online.

Spectrophotometric sensors facilitate the continuous monitoring of a process via the analysis of a relatively large sample volume. This means that collected data becomes more representative of the temporal and spatial changes taking place in the process, maximizing the accuracy of sampling and the value of the information acquired.

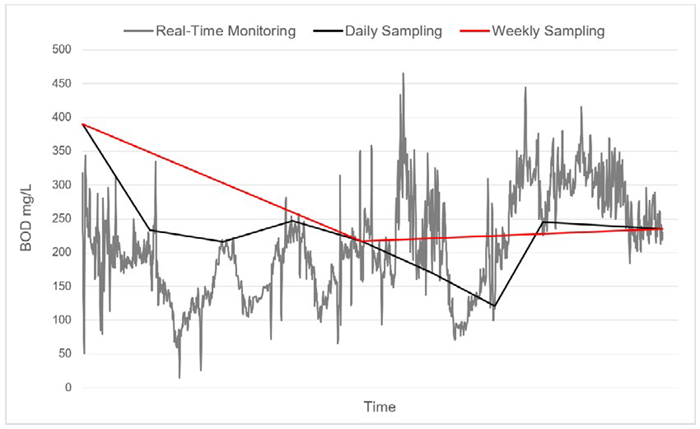

Figure 1 showcases the value of increasing data collection frequency, with events that would otherwise go unnoticed with grab sampling alone being revealed as more information on the process is obtained.

Figure 1. Effect of sampling frequency on the resolution of BOD variations in the water with real-time data in grey, daily sampling in black and weekly sampling in red. Image Credit: ABB

Another key advantage of real-time spectrophotometers for water and wastewater applications is their relative simplicity. The measurement process requires no sample preparation, reagents, or sample composition change. Operation is very straightforward, with easy and cost-effective maintenance of the instrument.

Spectrophotometric sensors open up new opportunities for process control applications, but questions have arisen around how a parameter, such as BOD, can be measured in real time when it traditionally takes a total of five days to test this.

Spectrophotometric sensors measure the sample’s UV-VIS absorbance as it continuously flows through the instrument, with absorbance understood as being directly proportional to concentration.

Taking the absorbance data from a specified time and matching this with BOD laboratory data for the same specific time allows a relationship between these two pieces of information to be established.

Collecting enough of these matching data sets provides the information needed to build a ‘calibration,’ which is utilized by the spectrophotometric sensor software to continuously convert measured absorbance data into a milligrams per liter (mg/L) value for BOD.

This calibration allows the operator to rapidly interpret the currently displayed BOD mg/L value to transmit real-time BOD mg/L data to a SCADA or PLC for process control and improvements, or to provide it as part of regulatory assurance processes.

The sensor manufacturer will develop a custom calibration using site-specific data, ensuring that the sensor delivers the most accurate results. This custom calibration is uploaded to the sensor’s controller via remote connection, allowing the controller to display a real-time BOD value for the sample currently being measured.

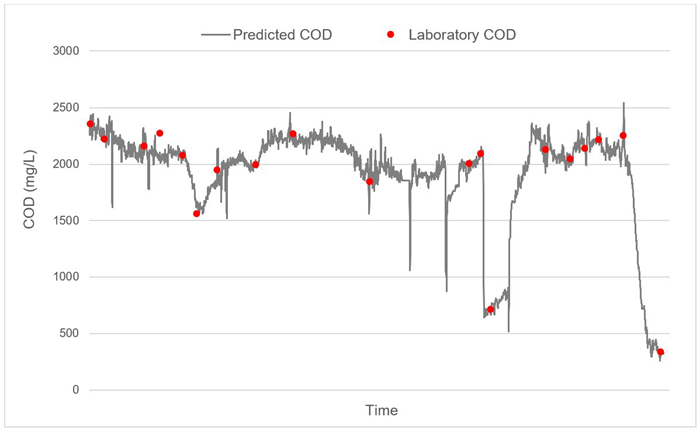

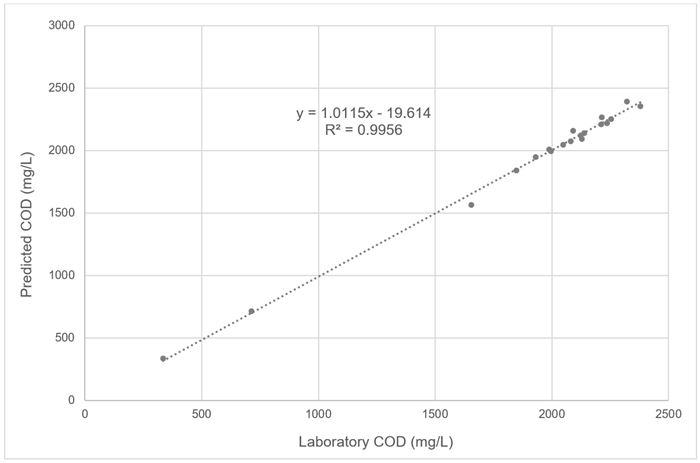

Custom calibrations are exceptionally robust (Figure 2 and Figure 3) because they take unique plant-specific wastewater characteristics into account. These characteristics can potentially influence the BOD, COD, or TOC composition, for example, of multiple product lines, process chemicals, dyes, and cleaning agents.

Regular audits are done on the calibration to confirm the validity of the real-time data. Audit samples can also be added to the custom calibration data set, continually improving the calibration’s robustness and accuracy over time.

Involvement at the plant level is straightforward, simply requiring operators to undertake routine maintenance in line with that of any online continuous wastewater instrument.

The sensor manufacturer generally provides the calibration work, allowing operators to obtain much-needed information without complex setups or configurations.

Figure 2. Real-time COD data from UV-VIS sensor with custom calibration and laboratory COD results. Image Credit: ABB

Figure 3. Comparison between laboratory COD data and COD data from UV-VIS sensor with custom calibration. Image Credit: ABB

Spectrophotometry is a widely utilized method that is now available for real-time analysis. By matching a series of time-stamped grab sample laboratory test results to the corresponding data from a UV-VIS sensor, a custom calibration is obtained that is highly accurate for the given site.

Implementing real-time spectrophotometric monitoring for BOD, COD, TOC, and other parameters and compounds has various beneficial outcomes. These include more informed decision-making, greater process control, optimization of chemical and nutrient dosing, optimization of system performance, reduction in effluent surcharge fees, and reduction in product lost to wastewater.

The wide detection capabilities of UV-VIS analysis monitoring also allow additional processes such as dye (color) concentration monitoring or clean-in-place (CIP) to also bring significant value. Real-time analysis represents a simple, cost-effective means of achieving a more complete understanding of wastewater and its related processes.

Acknowledgments

Produced from materials originally authored by ABB Measurement & Analytics.

This information has been sourced, reviewed and adapted from materials provided by ABB.

For more information on this source, please visit ABB.