I am currently an Associate Professor at the University of Texas at Austin. My Ph.D. dissertation investigated thin film mechanics for flexible electronics, and my postdoctoral training enabled me to design and fabricate bio-integrated soft electronics. I found it fascinating because it bridges the biotic and abiotic worlds, helping connect the human body into the internet of things (IoT) for many different purposes, including mobile health and human-machine interaction. It is a fundamentally challenging and intrinsically multidisciplinary topic.

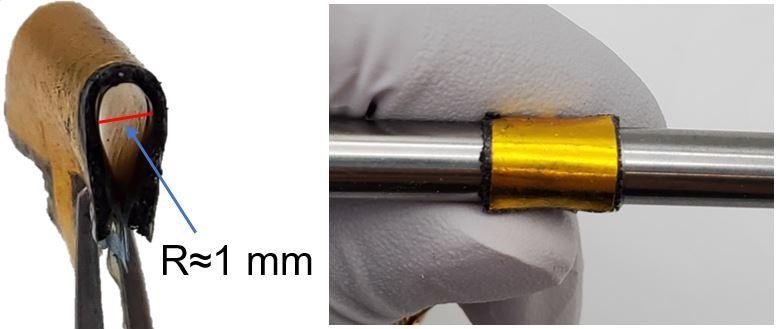

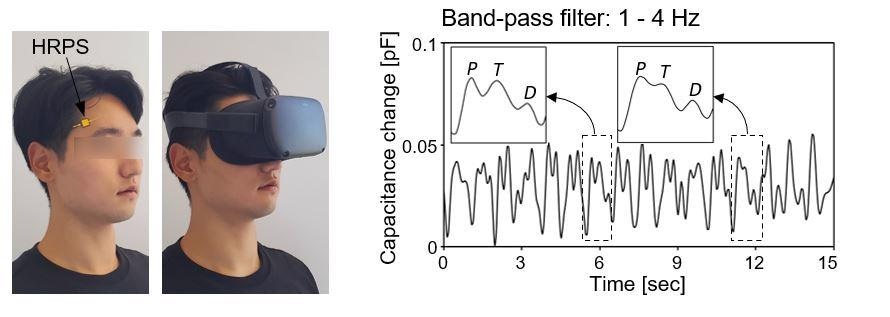

My vision is that humans will increasingly live, collaborate and eventually even merge with robots. That’s why my group has been focusing on e-tattoos for digitizing the human body. This hybrid response pressure sensor is our latest and most sensitive mechanical sensor, accurately measuring pulse waves noninvasively from the skin surface.

Flexibility of the hybrid response pressure sensor. Image Credit: The University of Texas at Austin

Many sectors within the medical industry have seen tremendous advancements over the last decade. How has medical sensing technology evolved during this period?

Medical sensing, especially mobile and at-home sensing, is finally taking off thanks to the maturity of wearable electronics, including the Apple Watch, Oura ring, and so on. However, the sensing positions are still quite limited. Brain, heart, muscle, and knee sensing require further development of wearable electronics. Skin soft, hair-thin, wear-and-forgettable e-tattoos that can be patched anywhere on the skin offer great flexibility on the sensing location.

The development of this new hybrid sensor is a significant breakthrough for flexible pressure sensor technologies. Although this will be highly relevant to many sectors, where do you think this innovation will have the most impact?

That’s very true. For a human to work with or merge with robots, robots also have to better mimic human behavior; this requires e-skins that can imitate the human sensation of pressure, temperature, and so on. Therefore, I also envision our hybrid response pressure sensor to be very useful for soft robots, endowing them with a human-like pressure sensation and the ability to endure any deformation of the robot.

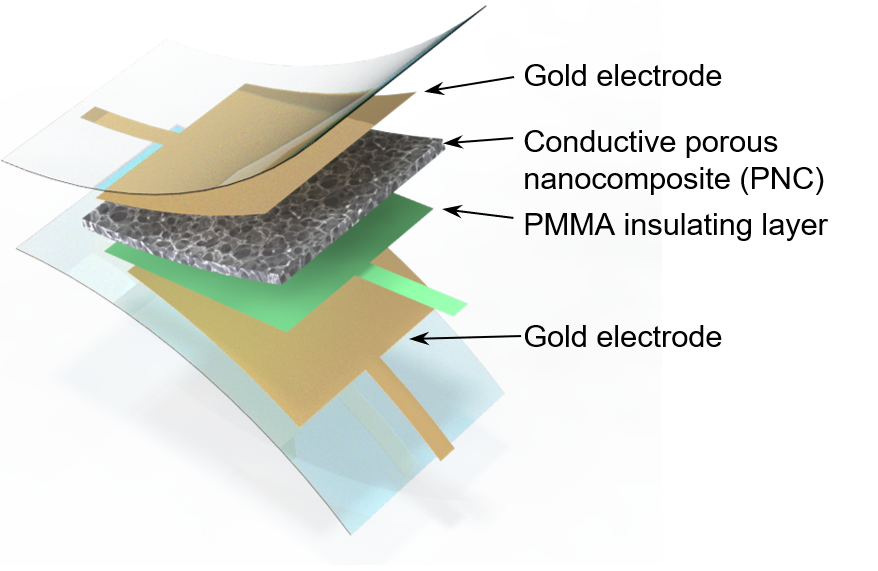

Construction of the hybrid response pressure sensor. Image Credit: The University of Texas at Austin

How did the research team approach the industry's "bottleneck" that has been troubling researchers for many years?

The “bottleneck” refers to the tradeoff between sensitivity and pressure range due to the purely piezocapacitive sensing mechanism in conventional capacitive sensors that utilize dielectric materials for pressure sensing. In our research, instead of dielectric materials, we used a high resistive conductive porous nanocomposite (PNC) as the pressure sensing material.

To make the overall device remain capacitive, we added an ultrathin dielectric layer just for electrical insulation. The PNC changes both resistance and capacitance when subjected to pressure, both of which contributed to the overall capacitance change of the device. Hence, our hybrid response pressure sensor can break the tradeoff and offer up to a 4-fold enhancement in sensitivity at a large pressure range (beyond 20 kPa).

Texas Engineering Researchers Solve Challenging Bottleneck with Soft Pressure Sensor Breakthrough

Texas Engineering Researchers Solve Challenging Bottleneck with Soft Pressure Sensor BreakthroughVideo Credit: CockrellSchool/YouTube.com

What major obstacles did the team face when developing this innovative sensor, and how were they overcome?

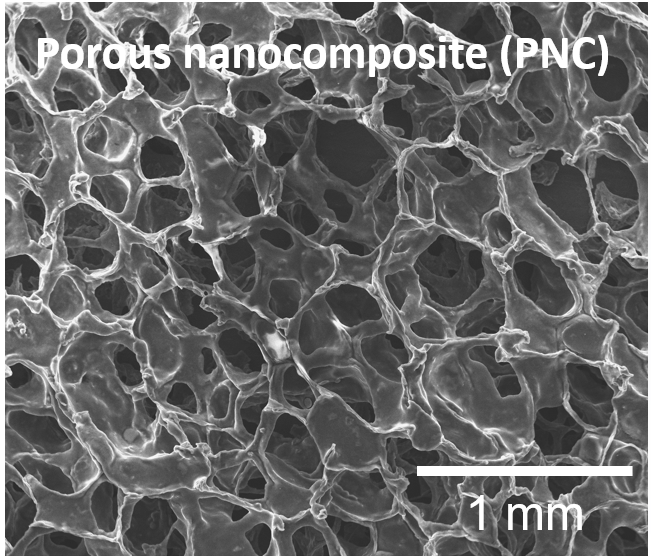

The biggest challenge is to determine the right resistivity for the PNC because if it is too high (i.e., not electrically conductive), it becomes an ordinary dielectric layer, and the device becomes a conventional pressure sensor. If it is too low (i.e., highly electrically conductive), it becomes part of the top electrode and loses the piezocapacitive response.

We had to build a circuit model to determine the optimal resistivity which can be tuned through the carbon nanotube (CNT) doping.

A key component of this hybrid sensor is its ability to be both piezo-capacitive and piezo-resistive. Do you think the success of this dual approach will trigger a shift in how the sensors industry approaches flexible pressure sensor design?

Yes, I believe future high-performance capacitive pressure sensors will benefit significantly from our innovation of the hybrid response pressure sensor.

The inclusion of a highly porous nanocomposite layer aided the successful development of this soft pressure sensor.

Porous nanocomposite (PNC) with carbon nanotube (CNT) doping for electrical conductivity. Image Credit: The University of Texas at Austin

Why are multidisciplinary approaches like this essential in the sensors sector, and when designing innovative solutions overall?

Multidisciplinary approaches are important in sensors development which has to involve material processing, device fabrication, and electrical knowledge of the sensing mechanism. We had to put the pieces together to eventually finish building the device and provide a fundamental understanding of its working principle.

Can you see any limitations on the adoption of this technology, particularly in the field of medical sensors?

There are limitations in terms of large-scale manufacture, how to limit sample-to-sample variation, and so on. Medical interpretations of the pulse waves measured by the wearable pressure sensor is another field of study.

HRPS measuring temporal arterial pulse, even under VR headset. Image Credit: The University of Texas at Austin

What are the next steps for this field of research?

The reported hybrid response pressure sensor is only flexible, not stretchable. We are in the process of making it stretchable so that it can be mounted on soft robots as pressure-sensing e-skins. It will open up another exciting playground.

Where can readers find more information on the progression of flexible pressure sensors?

Readers interested in flexible pressure sensors and e-tattoos are welcome to visit my webpage https://sites.utexas.edu/nanshulu/ as well as follow my Twitter @nanshulu.

About Dr. Nanshu Lu

Dr. Nanshu Lu is currently Temple Foundation Endowed Associate Professor at the University of Texas at Austin. She received her B.Eng. from Tsinghua University, Beijing, Ph.D. from Harvard University, and then Beckman Postdoctoral Fellowship at UIUC. Her research concerns the mechanics, materials, manufacture, and the integration of soft electronics on humans and robots. She has been named 35 innovators under 35 by MIT Technology Review (TR 35). She has received US NSF CAREER Award, US ONR and AFOSR Young Investigator Awards, 3M non-tenured faculty award, and iCANX/ACS Nano Inaugural Rising Star Lectureship. She has been selected as one of the five great innovators on campus and five world-changing women at the University of Texas at Austin. She is named a highly cited researcher by Web of Science.

Dr. Nanshu Lu is currently Temple Foundation Endowed Associate Professor at the University of Texas at Austin. She received her B.Eng. from Tsinghua University, Beijing, Ph.D. from Harvard University, and then Beckman Postdoctoral Fellowship at UIUC. Her research concerns the mechanics, materials, manufacture, and the integration of soft electronics on humans and robots. She has been named 35 innovators under 35 by MIT Technology Review (TR 35). She has received US NSF CAREER Award, US ONR and AFOSR Young Investigator Awards, 3M non-tenured faculty award, and iCANX/ACS Nano Inaugural Rising Star Lectureship. She has been selected as one of the five great innovators on campus and five world-changing women at the University of Texas at Austin. She is named a highly cited researcher by Web of Science.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.