Sponsored by BinMasterReviewed by Olivia FrostJun 4 2025

Choosing between point and continuous level sensors can be a complex decision, and narrowing down the right option within each category can be just as challenging. BinMaster helps users navigate the nuances of level measurement, offering guidance to select the most suitable sensor for their specific needs.

Image Credit: muratart/Shutterstock.com

Point Level Sensors

The point level sensor is an effective industrial solution for such scenarios. These sensors provide a straightforward yet impactful way to enhance return on investment (ROI) by preventing significant issues such as overflowing grain bins or production delays.

While there is a point level sensor suitable for any solid, liquid, or powder application, selecting the ideal option requires careful consideration and research.

First, assess the size, position, and layout of a vessel to determine the optimal mounting location for sensors. High-level indicators maximize efficiency by enabling users to fill a vessel to capacity, while low-level indicators ensure users remain informed when material levels are low.

Point level sensors can also be integrated to initiate or halt processes based on material levels. Opting for fail-safe models provides an additional layer of protection in the event of outages.

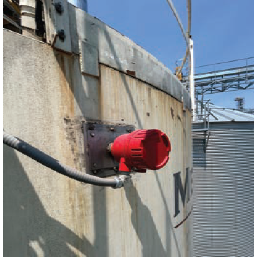

A BMRX-100 rotary set to indicate at high material levels. Image Credit: BinMaster

Rotary sensors are among the most popular choices. When connected to a horn, alarm, or light panel, they alert users when material interacts with or departs from the rotary’s paddle. Rotaries can be mounted in various configurations to offer convenient high, mid, and low-level indications.

Capacitance probes represent another highly customizable option. These sensors measure the difference between the dielectric constant of a material and the surrounding air, resulting in a highly accurate and fail-safe alert system that can be linked to a light, horn, or point level alarm panel.

Vibrating rods utilize piezoelectric energy to measure high and low-level values through the vibration of a blade. When material covers the vibrating blade, it triggers a relay switch that halts the vibration and activates an alert. When the material is removed, the blade resumes its vibration.

For cost-effective solutions, consider a diaphragm switch for highly sensitive, mechanically operated level measurements. When material contacts the switch, an alarm is activated. Alternatively, the classic tilt switch sensor alerts users to status changes when tilted 15 degrees or more.

Each of these sensors offers distinct advantages, but it is essential users consider their vessels and the appropriate price point for the setup.

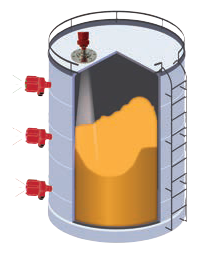

Combined use of point & continuous sensors grants peak efficiency. Image Credit: BinMaster

Point Level Advantages

- Affordable, often fitting within maintenance, repair, and operations (MRO) budgets.

- Proven reliability in agricultural, plastics, cement, food processing, aggregate, and mining environments.

- Long-lasting, easy to install, and customizable to suit any vessel.

Point Level Sensors

Rotaries

Image Credit: BinMaster

Ideal for level detection in powders, pellets, and granular materials. Choose from BinMaster’s economical mechanical BMRX-100, the popular fail-safe BMRX-200, or the latest premium model with an LED light alert, the BMRX-300 (formerly the MAXIMA+).

Additionally, mini rotaries are available for confined spaces, along with custom rotary extensions for oversized bins or silos.

Capacitance Probes

Image Credit: BinMaster

BinMaster’s PROCAP sensors can be customized, configured, and assembled to best meet operational needs. These fail-safe sensors are highly responsive, detecting changes in capacitance with precision as small as one picofarad (pF). They are available in standard and compact sizes with numerous mounting options.

Vibrating Rods

Image Credit: BinMaster

The VR-21 is an excellent choice for low-dielectric or lightweight powders and flakes with densities as low as 1.25 lb/ft3. BinMaster offers a range of standard, extended, and compact models, along with flexible and rigid extensions, making these devices highly customizable and effective.

Optional remote electronics and specialized probes are available for high-temperature applications up to 482 °F.

Diaphragm Switch

Image Credit: BinMaster

With the BM-45, you can eliminate issues with clogged chutes and bin overfills. It can initiate or halt processes as needed. Alternatively, the BM-65 is designed as an explosion-proof switch, ideal for free-flowing solids within a temperature range of -40 °F to 300 °F. It can be mounted internally or externally, depending on user requirements.

Tilt Switch

Image Credit: BinMaster

The BM-TSM is custom-built for each bin and can be configured for fixed or hanging mounting in silos, pits, or over conveyor belts and piles. This is a safe, mercury-free, non-powered, pendulum-type design that makes tilt switches straightforward and highly versatile.

Continuous Level Sensors

While point level sensors have their place, many operations require real-time visibility into levels within bins, tanks, silos, or other vessels. That’s where continuous level sensors come in, offering a more advanced solution for ongoing monitoring.

These sensors include technologies such as 3D scanners, guided-wave radar, open-air radar, weight-and-cable systems, laser, and ultrasonic sensors. Each offers unique advantages, and all are compatible with digital display consoles and inventory management software accessible via PC or mobile devices.

When selecting a continuous level sensor, it’s important to consider key factors: What level of accuracy and measurement frequency do you need? Are you measuring solids, powders, or liquids? Will the sensor be exposed to corrosive materials or chemicals?

Among these options, non-contact radar is widely considered the gold standard. Its focused 80 GHz radar signal cuts through dust, turbulence, and foam, delivering precise distance measurements between the sensor and material surface.

This data is then sent directly to a display or to BinCloud® software for easy access on desktop or mobile. Installation is flexible, with simple adjustments for angled roofs or radar beam alignment using the appropriate mounting equipment.

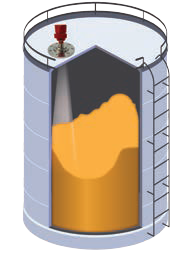

SmartBob in action, installed on a bin roof for level measurement. Image Credit: BinMaster

For more complex applications, the 3D Level Scanner stands out as the only sensor capable of mapping multiple points on a material surface. It’s particularly effective for bins with peaks, sidewall buildup, or uneven surfaces. The system uses acoustic pulses that reflect off the material surface and are converted into distance data and 3D visualizations.

Another option is the SmartBob® sensor, which functions like an automated tape measure. It lowers a weighted cable until it contacts the material, then retracts while counting pulses. These pulses are converted into accurate level readings delivered directly to the user.

Ultrasonic sensors offer reliable non-contact measurements for liquids up to 50 feet, performing well in both indoor and outdoor environments.

Battery-powered lasers are a cost- and energy-efficient choice. They require minimal wiring and integrate easily with BinCloud applications. For established reliability, guided wave radar uses time domain reflectometry (TDR) to measure distance, level, and volume in both solids and liquids.

No matter your budget, material type, or team size, continuous level sensors provide a dependable, time-saving solution that reduces effort, improves accuracy, and enhances operational control.

Radar sensors send real-time levels right to your BinCloud® software. Image Credit: BinMaster

Continuous Level Benefits

- Connects to software or display consoles for convenient monitoring.

- Simplified configuration with Bluetooth and BinDisc setup options.

- Robust sensor designs suitable for diverse industrial environments.

Continuous Level Sensors

Non-Contact Radar

Image Credit: BinMaster

The NCR-86's versatile radar technology is unaffected by variations in temperature, pressure, humidity, noise, condensation, or buildup, establishing it as the gold standard for non-contact sensors.

For a compact alternative with similar capabilities, consider the CNCR series: 100, 200, or 300 models.

3D Level Scanner

Image Credit: BinMaster

For comprehensive 3D imaging of material topography, accurate reporting on cone conditions, and volumetric accuracy that exceeds other devices on the market, the 3D Level is the ideal option.

High-temperature variants are also available, and a multi-scanner system can be implemented for larger bins.

SmartBob®

Image Credit: BinMaster

Featuring a dual-compartment design that protects its mechanical and electronic components, the SmartBob ensures longevity and maintenance-free measurements up to 150 feet.

As one of the most advanced cable-based inventory measurement tools available, it delivers accurate results from various angles, materials, and across multiple industries.

Ultrasonic

Image Credit: BinMaster

The ToughSonic®-100 is designed to excel in harsh factory environments for precise liquid level measurement. For even more demanding conditions, the ToughSonic®-200, constructed from chemical-resistant polyvinylidene fluoride (PVDF, or Kynar®), is an ideal choice.

Users can select from various cable lengths to accommodate any vessel.

Laser

Image Credit: BinMaster

This battery-powered, cost-effective solution requires minimal maintenance and utilizes proven, accurate technology.

BinMaster’s single point laser (SPL-200), FeedView® laser (FVL-200), and level transmitter (LL-100) each deliver consistent and convenient measurements that are transmitted directly to BinCloud software.

Guided-Wave Radar

Image Credit: BinMaster

Opt for the GWR-2000 for vessels containing powders or solids up to 100 feet tall or the GWR-3000 for liquid tanks or standpipes up to 75 feet. Both models offer exceptional accuracy within 0.08 inches (2 mm).

The GWR features a simple setup via Bluetooth and/or the BinDisc interface, enhancing usability.

This information has been sourced, reviewed and adapted from materials provided by BinMaster.

For more information on this source, please visit BinMaster.