Radar measurement has traditionally been the most effective method for examining stock levels in large silos and containers. The contents of portable containers, such as IBCs, on the other hand, are often calculated with only a cursory check, if at all.

For this type of application, VEGA offers VEGAPULS Air. Using the compact sensor in a paper mill demonstrates how it can be quickly and adaptably installed, delivers precise measured values, and delivers these benefits with radar technology.

Image Credit: VEGA Grieshaber KG

Paper, cardboard, and paperboard are extremely lightweight and economical packaging materials. Nowadays, the vast majority of cardboard items are created from recycled wastepaper.

DS Smith is one of the top manufacturers of paper products, sustainable packaging options, and recycling services in Europe. The mill, established in 1657, currently produces containerboard products (liner and medium grades) entirely from waste paper.

We recycle about 400,000 tons of paper and cardboard every year and produce new paper from it. Our main customers then use the paper to produce boxes, trays, and displays.

Marco Verkerk, Coordinator, Technology & Product Support, De Hoop Plant

On the suburbs of the Dutch town of Eerbeek stands the De Hoop plant.

In addition to emphasizing environmental friendliness and sustainability in production, DS Smith is always searching for methods to develop packaging that utilizes less raw material.

Processes Fine-Tuned to Each Other

The fundamental manufacturing procedures for recycling paper scarcely altered during the last few decades. Waste paper bales are ground into pulp with warm water and vigorous pulverization in pulpers. The pulp is then purified of all contaminants.

The cleaned paper fibers ultimately arrive at one of the two paper machines, where they are converted into new paper at 50 km/h. Customers create cardboard boxes and trays with this material. However, the paper can also be utilized for a door’s inside and the external layers of plasterboard.

Image Credit: VEGA Grieshaber KG

Although the procedures appear simple at first appearance, they require precise measurement and the addition of several raw ingredients.

Verkerk added, “That is why there are several intermediate stages, where both solid and liquid ingredients and additives are fed into the process. This includes various liquids, which are introduced into the production process from standard IBCs of 1,000 liters each.”

The levels in the tanks and silos have been measured for more than ten years using VEGAPULS or VEGABAR level measuring devices, which transfer the measured data for processing in a PLC.

Sensors like VEGAWELL, VEGASON, and VEGADIF are also utilized at various points throughout the plant. For instance, on paper machines, storage silos, and pipelines carrying incoming raw materials, auxiliary materials, and residual flows.

How Many Different Auxiliary Materials are Still Stored in IBCs?

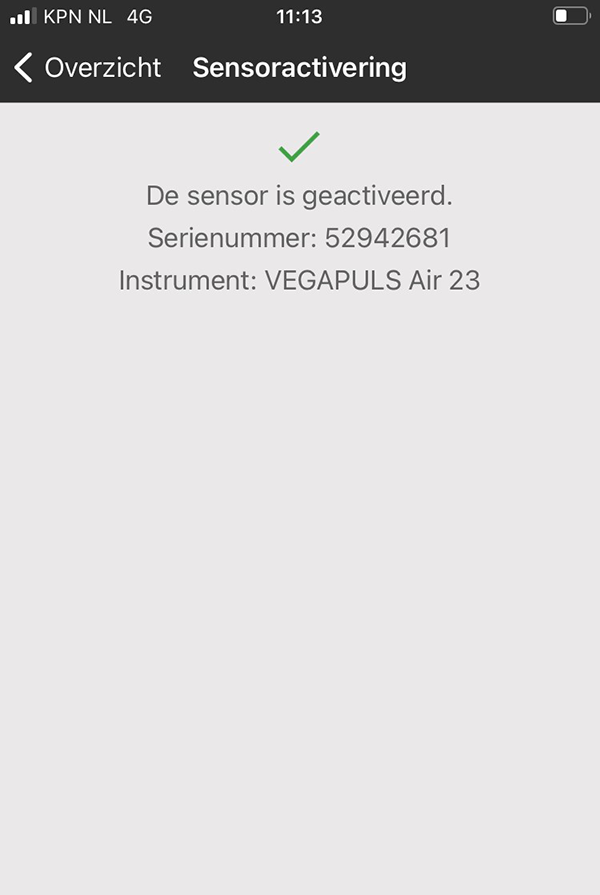

The latest measuring device from VEGA has been used successfully at the Dutch plant since July 2020. On the exchangeable IBCs, three VEGAPULS Air 23 sensors were first mounted as a test.

“We store more than 40 different chemicals and auxiliary materials in silos and IBCs. The fixed storage tanks and silos are already equipped with a level sensor connected to a PLC. The values are fed into our MBS program to control the process. This way we know exactly what the consumption levels are like, so we can order raw materials to ensure that production continues without interruption,” Verkerk stated.

Image Credit: VEGA Grieshaber KG

However, this mode of operation had not been conceivable with the mobile IBCs.

Verkerk added, “Generally, we don’t need every auxiliary material for every type of finished product. So, we drove through the plant every day to manually estimate the quantities in the IBCs.”

He stated, “Our experiences with the VEGA instruments we have used up to now have been very good. So, in September 2019, we asked VEGA if they had a solution for the IBCs. Unfortunately, the new instrument was still in the development phase.”

Everything in View

It was not until a few months later that DS Smith De Hoop B.V. became the first company to use VEGAPULS Air 23 to monitor levels in IBCs. These affordable, adaptable, and reliable wireless, autarkic sensors can be rapidly and easily implemented. The primary focus of their development was energy efficiency.

This required flawless coordination of measurement performance, wireless data transfer, and energy usage. Batteries offer energy management that assures a service life of up to 10 years when combined with optimal measurement cycles.

The sensors are extremely simple to connect to IBCs owing to adhesive adapters or flexible belt installation. They can be used reliably wherever levels need to be detected.

Image Credit: VEGA Grieshaber KG

The IBC plastic tank does not need to be opened or modified because measuring could be done from the outside with the help of radar technology. This solution can be quickly installed and kept on the container indefinitely.

No matter where the IBC is positioned, the liquid level is transmitted. The measurement/transmission interval is six hours, and the fixed measuring range is 1.2 m.

The VEGA sensor on each container captures the current level and its position multiple times daily and transfers this data wirelessly to the cloud, even when the containers are stacked on top of one another.

Due to these capabilities, the new instruments are practically made for use in IoT applications. The VEGA Inventory System can additionally receive the measured values from the sensors over a mobile network (NB-IoT/LTE-M1).

Quick Setup and Commissioning

VEGAPULS Air 23 was first installed in the plant’s three IBCs. Removing the protective film and sticking the sensor on was all that was required for installation. The water-tight, plastic-encapsulated antenna of VEGAPULS Air, which uses 80-GHz radar technology, allows it to measure the level directly through the IBC’s plastic top.

Verkerk noted, “We had previously considered whether we could get along with a wire-connected radar instrument. But at the locations where the IBCs are deployed, connecting with cables was extremely difficult and the time savings would not have offset the investment costs.”

Image Credit: VEGA Grieshaber KG

The installation of VEGAPULS Air did not require any permissions or process fittings. It is not necessary to use materials with particularly strong chemical resistance since the device measures through the container roof from the outside.

The type of medium in the IBC is irrelevant. Another major benefit is that the IBC can be thoroughly cleaned from the outside since the sensors are protected by IP68 and IP69K standards.

Experiences as a First User

Recalling his experience, Verkerk added, “We were among the first to use the new instrument and thus experience how it really works in practice.”

He believes that double-sided adhesive is adequate for securing the sensor to the IBC.

He further stated, “Once, in the course of an IBC replacement, we forgot to remove the adhesive on the sensor and mount it on the new IBC. We found it a week later lying on the forklift.”

As soon as it was glued back to the proper IBC, it began providing accurate readings right away.

This information has been sourced, reviewed and adapted from materials provided by VEGA Grieshaber KG.

For more information on this source, please visit VEGA Grieshaber KG.