The air pressure inside an airplane cabin fundamentally differs from the air pressure outside the aircraft when in flight. This pressure difference enables aircraft to fly and people to breathe comfortably at high altitudes.

Image Credit: Superior Sensor Technology

Improper cabin pressurization can, however, result in dangerous scenarios that affect passenger safety and comfort. This is why monitoring and managing cabin air pressure is essential for aircraft operation and design.

Unlike ground-level atmospheric pressure, airplane cabin pressure must be precisely controlled and constantly monitored. Even subtle pressure changes at 35,000 feet altitude can have a big influence on the human body and aircraft equipment.

Therefore, precise and dependable cabin pressure measurements are critical, particularly on long-haul flights across varying weather patterns and altitudes.

Differential pressure sensors are essential when it comes to enabling airlines and pilots to constantly monitor cabin air pressure and altitude changes.

These specialized sensors provide real-time data by comparing interior cabin pressure to external atmospheric pressure, allowing pressurization system modifications while maintaining passenger comfort and safety.

What is Cabin Pressure, and Why is it Monitored?

The cabin pressure inside an airplane refers to the air pressure within the cabin during flight. Unlike buildings on land, the cabin of an airplane must be pressurized to provide a safe and comfortable environment for passengers and crew members.

At sea level, the air pressure is approximately 14.7 psi (pounds per square inch). As an aircraft climbs, the outside air pressure drops considerably. Without pressurization, the air pressure within the aircraft would drop to catastrophically low levels.

The FAA requires passenger airplanes to maintain cabin pressure similar to an altitude of 8,000 feet or less. This maintains the cabin altitude low enough to provide adequate oxygen levels for passengers and crew members.

When flying at cruising altitude, the optimal cabin pressure range is between 6,000 and 8,000 feet. The cabin pressure is monitored using instruments that measure the difference in pressure between the inside and outside air. If cabin pressure goes outside the optimal range, it can have adverse effects on human health and comfort:

- At cabin altitudes of 8,000 feet or above, decreasing air pressure means less oxygen reaches the lungs. Passengers may experience hypoxia, which causes headaches, tiredness, and nausea.

- As an aircraft climbs, the Eustachian tubes balance pressure between the outer and middle ear. Pressures higher than the optimal range can, therefore, cause ear or sinus discomfort

- Extremely low cabin pressure at very high altitudes can lead to life-threatening hypoxia. In the past, cabin depressurization accidents have resulted in some passenger fatalities.

Figure 1. Boeing 737 Cockpit Pressurization Panel. Image Credit: Superior Sensor Technology

To mitigate these risks, FAA Federal Aviation Regulations (FARs) impose specific pressurization requirements:

- According to FAR 25.841, aircraft carrying ten or more passengers must maintain a cabin pressure altitude of no more than 8,000 feet at their maximum operating altitude.

- For airplanes with more than 19 passengers, the rate of cabin pressure change cannot exceed an equivalent shift in altitude greater than 500 feet per minute.

- At higher altitudes, the cabin pressure difference cannot exceed nine pounds per square inch to prevent excessive strain on the fuselage.

By continuously monitoring the cabin pressure and adjusting it as and when needed, the onboard systems can stabilize the pressure within a safe range for human occupation during flight. Stabilization enables passengers to breathe comfortably even at cruising altitudes of 30,000 feet or higher.

The Role of Differential Pressure Sensors

Differential pressure sensors are crucial for monitoring and maintaining cabin pressure in commercial airplanes. These instruments monitor the difference between two pressure points: the pressure inside the cabin and the atmospheric pressure outside the aircraft.

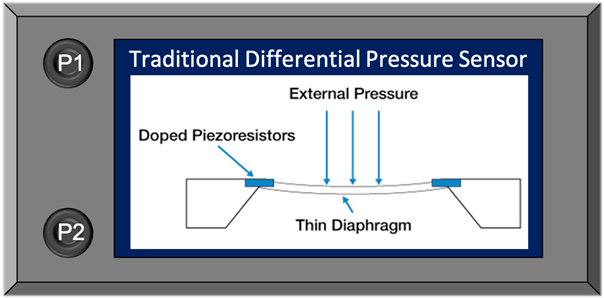

They operate by connecting two sides or ports, one to the "high" pressure region and the other to the "low" pressure area. Inside the sensor, a diaphragm flexes in response to pressure fluctuations. This flexing is then measured to calculate the pressure difference.

Figure 2. Internal workings of a differential pressure sensor. Image Credit: Superior Sensor Technology

These sensors are distributed throughout the aircraft's environmental control system. Some important locations include:

- On the outflow valve - to measure cabin pressure compared to ambient pressure

- In the air conditioning packs - to monitor airflow and filter performance

- At different points along the cabin ducting - to measure pressure changes

The aircraft's environmental control system employs real-time data from these differential pressure sensors to adjust cabin pressure and airflow accurately. Depending on sensor data, the system automatically adjusts the bleed air and outflow valve locations as altitude changes during flight.

These sensors send pressure data to the environmental control system many times per second, enabling smooth cabin pressure adjustment. If pressure deviates from typical levels, the crew receives an alert, allowing them to take corrective action. Proper sensor performance is crucial for passenger safety and comfort.

The benefits of employing differential pressure sensors in this application are considerable. They provide excellent accuracy, reliability, and quick response times, all of which are essential in the dynamic environment of an aircraft.

In addition, their ability to detect even subtle pressure changes makes them ideal for early warning systems, alerting crew members to possible problems before they become catastrophic.

The Challenges of Accurate Cabin Pressure Measurement

Accurately monitoring and maintaining cabin pressure poses several issues for aircraft designers and operators.

Altitude fluctuations during flight cause natural variations in external air pressure, which the cabin pressure control system must accommodate. Simultaneously, the measurement instrumentation must tolerate high vibration, noise, and turbulence.

Precision and reliability are vital. Even brief malfunctions or minor errors in cabin pressure monitoring can lead to passenger discomfort, health issues, or emergencies. Faulty pressure measurement can trigger unnecessary deployment of oxygen masks or, worse, a lack of alerts when cabin pressure drops unsafely low.

Ensuring accuracy requires careful sensor selection, installation, and continuous calibration. The position and placement of the external Pitot tubes and internal pressure sensors also play a significant role.

Minor calibration errors or signal amplification issues can cause pressure readings to be inaccurate. Engineers must consider all environmental parameters and employ robust cabin pressure sensors designed specifically for aircraft applications.

With passenger safety being a top priority, airlines and manufacturers invest heavily in creating, testing, and maintaining cabin pressure monitoring systems. While measurement technology has advanced tremendously, several opportunities remain to increase accuracy, reliability, and fault tolerance through constant innovation.

Case Studies

Differential pressure sensors for cabin pressure monitoring are widely used in different aircraft models and airlines. For example, the Boeing 787 Dreamliner, renowned for its sophisticated technology, relies on these sensors to maintain its revolutionary cabin pressure system, which is designed to enhance passenger comfort.

Early variants of the Boeing 787 Dreamliner faced challenges with cabin pressure fluctuations, causing discomfort for passengers. The investigation discovered problems with the differential pressure sensor system, which needed to be optimally calibrated for the aircraft's specific pressurization dynamics.

The sensor system was adjusted to enhance its accuracy and integration with the aircraft's control systems, eliminating the problem.

Figure 3. Quatas 737-438 Aircraft. Image Credit: Superior Sensor Technology

There have been several instances where differential pressure sensors have played an important role in aviation safety.

One famous example is the 2008 incident involving Qantas Flight 30 (Boeing 747-438), where a rapid loss of cabin pressure resulted in an emergency descent. The aircraft's differential pressure sensors were critical in detecting the problem quickly, allowing the crew to take immediate measures to ensure the safety of everyone on board.

Conclusion: Navigating the Skies with Precision and Care

Cabin pressure monitoring with differential pressure sensors is crucial for passenger comfort and safety. As discussed in this article, these sensors play an important role in ensuring optimum air pressure levels in aircraft cabins during flight.

Differential pressure sensors enable real-time monitoring and adjustments by comparing internal cabin pressure to external air pressure. This eliminates harmful cabin pressure fluctuations, which might cause ear or sinus pain, hypoxia, decompression sickness, or other hazards for passengers and crew.

Given the risks of equipment failures or sensor malfunctions, reliable and precise pressure readings are crucial. While challenges like turbulence and noise persist, advancements in sensor durability, calibration, redundancy systems, and data analysis continue to enhance cabin pressure measurements.

Proper sensor selection, installation, maintenance, and operation techniques are critical for improving pressure monitoring performance.

As the global demand for air travel grows, the underlying technology that allows for comfortable and safe air cabin conditions will become increasingly important. Differential pressure sensors will continue to play an essential role in commercial and private aviation.

References

- Boeing. (n.d.). 787 Dreamliner: The passenger experience redefined. [Boeing Commercial Airplanes ] (https://www.boeing.com/commercial/787/).

- Civil Aviation Safety Authority. (2008). In-flight upset event, 475 km north-west of Manila, Philippines, 25 July 2008, VH-OJK, Boeing 747-438. [Australian Transport Safety Bureau] (https://www.atsb.gov.au/publications/investigation_reports/2008/aair/ao-2008-053/).

This information has been sourced, reviewed, and adapted from materials provided by Superior Sensor Technology.

For more information on this source, please visit Superior Sensor Technology.