By combining a UAVs (Unmanned Arial Vehicles) with a high-resolution industrial-grade camera the cost of aerial imaging is significantly reduced. For such an experiment to be effective the data gathered needs to be RAW, uncorrupted and easily processed. Lumenera, experts in imaging, recently worked with AggieAir, a research lab at Utah State University, to develop an aerial imaging system for agricultural research.

We spoke to Corey Fellows, Sales Director at Lumenera, about the best drone/camera combination to use for aerial imaging, the benefits of using a scientific camera and the exciting new applications this technology is opening up.

What are the ideal features of a UAVs to be integrated with high resolution imaging technology?

The term UAV (Unmanned Aerial Vehicle), more commonly known as Drones, relates to aerial vehicles that can fly without a human pilot on-board. Instead, they are controlled remotely by an experienced pilot, or they can run an auto-pilot system that uses a combination of sensors such as cameras, GPS and altimeters to control their flight path.

A wide range of UAVs are commercially available, and they tend to be classified by their size, payload capability (the amount of extra weight that they can carry), and their flight time.

For commercial imaging, the most important feature is the UAVs payload capability. This needs to be high enough to allow the drone to carry the digital cameras themselves, embedded computers to capture and store the images, and also a suitable power source to run all of these electronics. This equipment tends to be measured in 100’s of grams to Kilograms depending on the number of cameras needed for an application.

When the payload required for a specific application exceeds the capabilities of a UAV, there is also the option of using traditional fixed-wing manned aircraft, which are capable of carrying more weight.

The majority of commercial imaging systems require RAW uncompressed images with typically large file sizes. Storing these images during flight takes a significant amount of computing space and power.

As most small micro-drones don’t have the necessary payload weight capacity and battery power to achieve this they are not a very good fit for data centric applications that need to run for longer periods of time. Mid to large drones tend to have decent payload capabilities and tend to be a much better fit when using industrial grade imaging solutions for commercial applications that are designed to run for extended periods of time.

Mid- to large-sized drones have the required payload capacity to carry industrial cameras. Image Credits: TOR_1D/shutterstock.com

What information about the environment can be obtained using a UAV/camera combination?

Combining a UAV with an industrial grade camera is a powerful tool for environmental monitoring.

UAV/camera systems allow large expanses of the environment to be imaged at a lower cost than using a manned aircraft, and can collect data far more rapidly than ‘on the ground’ methodologies. The use of drones also means that adverse environments can be studied extensively with no human risk.

A wide range of different camera-based, environmental studies are possible using a UAV. These include studies into environmental safety, such as the annual monitoring of flooding and overflowing rivers, automated inspection of oil and gas pipelines for potential faults, or determining grassland and vegetation health to assess the risk of a wildfire.

We recently worked with AggieAir, a research lab from Utah State University (USU), who wanted to develop a way of measuring the moisture content of soil over a wide expanse of land. This experiment was important to USU, who wanted to determine the health of vegetation in the regions studied. This application was so successful that AggieAir have used the technology in several other projects including the environmental tracking of invasive plant species or monitoring fish habitats.

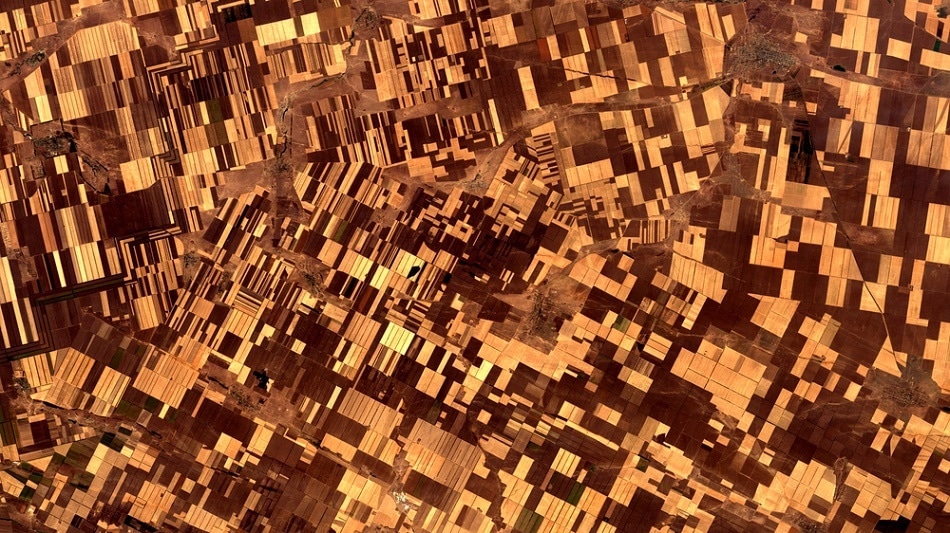

The aerial images captured using an industrial camera mounted to a drone can be stitched together to give a high resolution map of wide areas of land. Image Credits: Voran/shutterstock.com

What camera features were essential for the AggieAir project to be successful?

In order to accurately assess environmental conditions, it is important that the camera being used alongside the UAV provides pure, unadulterated data. It is for this reason that an industrial grade digital camera, rather than a consumer-grade camera, was an important component of the project.

Industrial grade cameras provide pure RAW data which has not been compressed or altered in any way, providing a higher level of precision than consumer cameras.

Consumer cameras have a tendency to ‘improve’ how an image looks, without the user’s knowledge, which can corrupt the usefulness as the data acquired. These ‘improvements’ include using physical items such as an anti-aliasing filter (which removes pixilation and the moiré effect by optically blurring the image thus eliminating details) and also software corrections such as sharpness, gamma and tone enhancements, all of which reduce the scientific accuracy of the images.

AggieAir Short Video

What other factors should be considered when selecting a camera for UAVs?

As cameras used in UAV applications are going to be exposed to the environment and undergo physical shock during the impact of landing they need to be durable. Lumenera’s industrial cameras are highly ruggedized – with a solid aluminium enclosure for protection and electronics which are designed to be resistant to adverse conditions. Additionally, they are covered by a four-year warranty, which accounts for rugged industrial applications.

It’s also important that the data transfer between the camera and computer is reliable to ensure no data is lost or corrupted during transfer. Lumenera uses a USB 3.0 interface for this purpose which provides an effective and efficient transfer of data. This interface is protected using a locking connector which means that the system is protected and retains its integrity even when being used on a daily basis in the field.

The image processing speed must also be high enough to provide a useful amount of data to the user. UAV imaging applications typically require a frame rate of 1-2 frames per second. This frame rate is vastly exceeded by Lumenera’s high-speed USB 3.0 connections – meaning UAV imaging systems using a Lumenera camera are future proofed and can also be used as part of a scaled-up multi-camera system.

The use of Multi-spectral imaging for UAV’s is extremely popular today. For most commercial applications, images are captured between the near-ultraviolet (NUV) and the far-infrared (FIR). Within this full spectrum of photography, silicon sensors (CMOS / CCD specifically) are usually only capable to capture data in the visible (VIS) and into the near-IR (NIR) spectrums ranging from 400-1000nm.

With the use of special filters and coatings, even a standard silicon sensor could image the results of UV light absorbing into these special coatings to collect even the smallest hint of UV light present.

From an application perspective, a UAV could use one of these modified silicon sensors to capture the Corona Effect in Power Systems to determine potential failure points in high voltage power lines. Other applications use multiple monochrome cameras and bandpass filters to target multiple wavelengths used to calculate applications like Normalized Difference Vegetation Index (NDVI) which require very specific data in the “near-Red” and NIR spectrums.

Industrial grade cameras are ideal for this scientific approach since monochrome cameras are widely available, can be tightly synchronized to each other, and can be automated through some simple software commands.

Why were the Lt965R and the Lt1265R the best cameras for the AggieAir project?

There were a number of reasons why AggieAir chose to work with Lumenera on their UAV project. Our willingness to support an API (application programming interface) for ARM-based processors with Linux OS was a key to their success.

The Lt965R and Lt1265R camera models offered them an impressive ground sample distance (GSD) alongside high precision 14-bit image data. The SWaP (size, weight, and power) for these cameras combined with their embedded PC and battery pack was an ideal payload size for their custom built fixed wing UAV solution.

The Lt965R industrial camera from Lumenera

Do you see this technology being used for other applications?

Yes of course, UAV/camera systems can be used in a wide range of applications and we expect to see Lumenera’s cameras being increasingly used for this purpose.

Aerial photogrammetry (using aerial photography for surveying and mapping) would benefit vastly from using Lumenera’s RAW, uncompressed 8 or 14-bit data. The low-noise images captured can then be stitched together and post-processed to create massive Gigapixel and Terrapixel 2D and 3D photo mosaics.

The defence industry can also use this technology to monitor important assets, either for real-time monitoring (with immediate feedback), or for continuous monitoring over longer periods of time.

We also expect this technology to be used commercially. UAV/camera technology can be used to monitor both large scale and small scale construction sites, and can also be used to inspect, and determine the health of, important infrastructure such as cell phone towers and high-voltage power lines.

By using a UAV these processes can be entirely automated, reducing the cost of such inspections whilst simultaneously removing human error.

Industrial Camera technology alongside a UAV can also be used to inspect large scale infrastructure such as power lines.

Does Lumenera offer assistance in selecting the correct camera for a specific application?

Absolutely, Lumenera’s team of experienced Sales and Technical staff are at hand to help you convert your idea into a workable solution.

This starts with our 30-Day Evaluation process, to hands-on camera and API integration, to providing suggestions on third party components such as the optics and PC to be used alongside the camera itself. Our team is also experienced in a variety of Operating Systems and development environments.

Where can our readers find out more about UAV projects and Lumenera’s cameras?

You can find information on the large range of cameras that Lumenera provide on our website. If you would like some more information on which camera would best suit your application don’t hesitate to contact us directly via [email protected].

We have also published a number of case studies and blog entries specific to UAV/camera systems which you will be able to find using the following links.

About Corey Fellows

As the Director of Sales at Lumenera, Corey is responsible for strategic account management and OEM business development across the Americas.

Corey has extensive experience in the global digital imaging industry, and has helped to create custom and OEM imaging solutions for a wide variety of industrial markets including: transportation, factory automation, biometrics and unmanned systems.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.