TRSYS20 is a precise measuring system employed to determine in-situ thermal resistance (R-value), thermal conductance (Λ-value), and thermal transmittance (U-value) of building envelope components.

Primarily used in accordance with ISO 9869, ASTM C1046, and ASTM C1155 standard practices, TRSYS20 features high-resolution electronics, two HFP01 model heat flux sensors, and two pairs of matched thermocouples for accurate differential temperature measurements.

Image Credit: Hukseflux Thermal Sensors B.V.

Specifications

Source: Hukseflux Thermal Sensors B.V.

| . |

. |

| Measurand |

heat flux (2 x), temperature (4 x), temperature difference (2 x) |

| TRSYS20 specifications |

: |

| Uncertainty of calibration |

±3 % (k = 2) |

| Measurement resolution |

0.02 W/m² |

| Guard width to thickness ratio |

5 m/m (as required by ISO 9869 D.3.1) |

| Accuracy |

< ± 0.1 °C (as required by ISO 9869, paragraph 5.2) |

| Measurement resolution |

0.02 °C |

| Thermocouple type |

IEC 60584-3:2007 type KX |

| Tolerance class |

Class II |

| Required data analysis to determine building R-value and U-value |

to be performed by the user according to ISO and ASTM standard practices |

| Standards governing use |

ISO 9869, ASTM C1046, ASTM C1155 |

| Number of measurement locations |

2 |

| Cable length per location |

location 1: 10 m, location 2: 20 m |

| Rated operating temperature range HFP01 and TC |

-30 to +70 °C |

| Measurement duration range |

> 3 days |

| Data storage capacity |

> 30 days |

| MCU specifications |

: |

| Connection |

to local area network (LAN) via ethernet or directly to PC via USB |

| Graphical user interface |

web page via web browser |

| Supported web browsers |

Chrome, Firefox, Internet Explorer, Opera, Safari |

| Rated operating voltage MCU |

10 to 16 VDC |

| Ingress protection class |

IP54 |

| PSU specifications |

: |

| Input voltage |

110-220 VAC, 50 / 60 Hz |

| Ingress protection class |

IP22 |

Description

Building Thermal Resistance Measuring System

The TRSYS20 system utilizes high-sensitivity HFP01 heat flux sensors in conjunction with robust, high-resolution electronics. This ensures that the TRSYS20 carries on making accurate measurements even in challenging conditions, especially at very low heat fluxes and minimal temperature differences across the wall.

The paired thermocouples enable precise temperature difference measurements with less than 0.1°C uncertainty across the entire temperature range. With two measurement locations providing redundancy, users can ensure the measurement results accurately represent the building envelope component.

Image Credit: Hukseflux Thermal Sensors B.V.

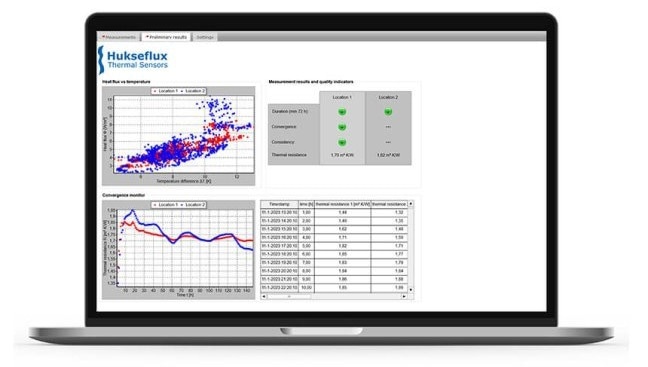

User Interface: MCU as a Web Server

TRSYS20 is operated through a PC, eliminating the need for software installation. The Measurement and Control Unit (MCU) can be linked to a Local Area Network (LAN) via Ethernet or directly connected to a PC through USB. The MCU offers a user-friendly graphical interface in the form of a webpage, which is accessible via any web browser.

Through this interface, users can start and stop experiments, monitor real-time heat flux, temperature, and temperature difference data, as well as review preliminary results.

The system produces a data file comprising measurement time, heat flux, temperature, and temperature difference data for the two measurement locations. This file is stored in the MCU and can be downloaded via the graphical user interface. Users are responsible for data analysis, calculating the R-, Λ-, or U-value of the building envelope, following ISO 9869 or ASTM C1155 standards.

Image Credit: Hukseflux Thermal Sensors B.V.

Unique Features and Benefits

- Best paperwork: Complies with ISO and ASTM standards

- Connection via ethernet (LAN) or USB

- Intuitive and easy-to-use graphical user interface

- Measures very small heat fluxes

- Robust and stable

- Simultaneous measurements in two locations

- Temperature difference sensors: tested for 0.1 °C accuracy requirements

- Water- (rated IP67) and corrosion-proof sensors

Image Credit: Hukseflux Thermal Sensors B.V.

Calibration and Conformity Assessment

TRSYS20 components are calibrated with traceability to international standards, and the system comes with formally traceable calibration certificates. The HFP01 heat flux sensors are calibrated following ASTM C1130 standards, and the temperature difference sensors are meticulously tested as individually matched pairs.

Image Credit: Hukseflux Thermal Sensors B.V.

Suggested Use

- Measurement of heat flow and differential temperature for determining building R-value, Λ-value, or U-value