The new Flow Detect 2000 with hazardous location approvals manufactured by BinMaster provides a solution to material contamination problems by using microwave Doppler technology to communicate flow or no flow status.

It features North American Class II, Division 1 Groups E, F, & G and ATEX Zone 21 hazardous location approvals. This affordable non-intrusive instrument is appropriate for solids, granules, pellets, meals and powdered materials and is suitable for most any industry including feed, grain, milling, food, cement, mining, power and plastics. This sensor is used in distributors, gravity chutes, pipelines, ducts, feeders, bucket elevators, gravity spouts, gravity feeders, mechanical or pneumatic conveyors. It prevents downtime caused by blockages, conveyors running empty, no material flow to-and-from a process, or loose slide gates that can cause production loss and equipment failure.

The BinMaster Flow Detect 2000 can be used as a control to significantly minimize or prevent the hazard of cross contamination by detecting whether material is still flowing through a distributor leg, chute, feeder, or pipeline used to transport materials during the production process. By detecting the presence or absence of material flow, cross-contamination can be avoided, preventing potentially dangerous and expensive USDA or FDA compliance issues at a facilities producing food for human or animal consumption. These devices can be used as part of a proactive prevention plan at processing facilities complying with the Food Safety Modernization Act (FSMA).

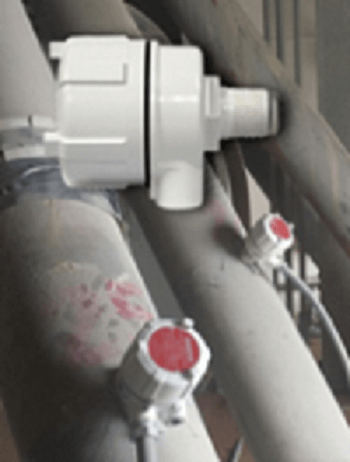

The Flow Detect 2000 houses the sensing element, power and output connections, and user adjustment controls in a single NEMA 4X enclosure. The sensor is easy to install through a 1-/14' NPT opening. It is completely non-intrusive and does not come into contact with the flow stream. A single analog relay output communicates flow or no flow status to a PLC. Both normally open (NO) and normally closed (NC) contacts are available. LED lights indicate power, flow/no flow and fault conditions.. It includes a switchable filter to reduce the effect of vibration and ensure the detection of moderate and fast-flowing materials.