Sep 23 2010

Georgia Institute of Tech’s team of biomedical scientists, and microelectronics engineers, has pioneered a new Biosensing technology that could supersede the traditional microplates used in biomedical diagnostic and research laboratories.

Microplates which are actually arrays of tiny test tubes used to test multiple samples, to determine their responses to antibodies and chemicals. Presence of specific gene sequences or proteins are associated with color changes or fluorescence in labels on plates. Researchers plan to substitute these microplates with microelectronics technology that includes disposable arrays, associated with thousands or more electronic sensors, linked to potent signal processing circuits. If successful, then a long time vision of personalized medicine i.e., where the physician is able to offer real-time diagnosis of diseases in his office, is achievable.

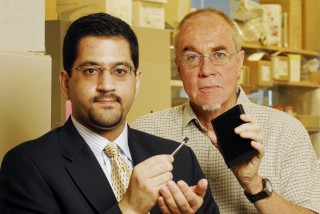

Associate professor Muhannad Bakir (left), from Georgia Tech’s School of Electrical and Computer Engineering, holds a prototype electronic microplate, while Professor John McDonald, from the School of Biology, holds an example of the conventional microplate it will replace

Associate professor Muhannad Bakir (left), from Georgia Tech’s School of Electrical and Computer Engineering, holds a prototype electronic microplate, while Professor John McDonald, from the School of Biology, holds an example of the conventional microplate it will replace

According to John McDonald, Professor at Georgia Tech School of Biology, and Chief research scientist at Atlanta’s Ovarian Cancer Institute, such a device would be able to identify gene mutations, indicating cancer in individuals, and then help in deciding the correct treatment needed. This technology is far superior to the current analytical and diagnostic technology. The new biosensor system’s mainstay is its ability to distinguish electronically, between tainted or infected and healthy cells, through differences in levels of ions present and mutations in DNA and proteins.

Muhammad Bakir, Georgia Tech’s Associated Professor (School of Electrical and Computer Engineering), stated that this project is an amalgam of electronics and molecular biology, where a sensing platform using nanoelectronics and 3D electronic systems have been created.

The 3D Sensor arrays are made using economical, high tech microelectronic technology, which though not perfect yet, but are still well suited for present day research and diagnostic laboratories. Data processing is carried out by reusable integrated circuits, linked temporarily to the array.

A prototype has been developed by the researchers, to showcase the biosensing system with silicon nanowire sensors, in a 16-well device, crafted on a 1cm x 1cm chip. This device recognized the difference between healthy ovarian cells of the epithelium, and ovarian cancerous cells at varied cell densities.

Papers related to this technology were presented at two conferences, the International Interconnect Technology conference in June 2010, and the Electronic Components and Technology Conference. This project was funded partially by bodies such as NNIN (National Nanotechnology Infrastructure Network), Georgia Tech’s IBSI (Integrative BioSystems Institute) and Semiconductor Research Corporation.