Jan 17 2018

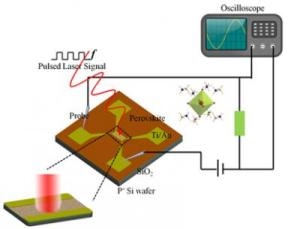

A recent paper published in NANO showed the gas-solid reaction method provides a full coverage of the perovskite film and avoids damage from the organic solvent, which is beneficial for light capture and electrons transportation, resulting in a faster response time and stability for perovskite photodetectors.

Credit: Dr. Guoqing Tong

Credit: Dr. Guoqing Tong

Pervoskite materials have long been considered candidates in the semiconductor manufacturing due to their characteristics of high light absorption, carrier mobility and wider light spectrum. They are widely applied in solar cells, light-emitted devices and photodetectors. However, the organic solvent in the traditional solution method will damage the perovskite film and form unstable phases during the synthesis process, which makes the perovskite film decompose quickly in wet conditions, limiting the practical application of perovskite devices. Considering the significant influence of the solvent, a team of researchers from Dongchang college of Liaocheng University and Hefei University of Technology proposed a new gas-solid process to fabricate the perovskite film. This non-solvent approach provides high crystallization and full coverage film in lower vacuum and low temperature systems.

The researchers investigated the morphology, light absorption and the crystal phases of the perovskite film at the different annealing temperature after gas-reaction to obtain the high-quality perovskite film. The devices exhibited high responsivity and detectivity of 5.87AW-1 and 1012 Jones. The response time of the device is estimated to be 248 μs/207 μs, which is faster than most previous reports via the solution method. Remarkably, the responsivity and detectivity are estimated to be 0.26 AW-1, 2.13×1010 Jones after lasting exposure in air (25oC, RH~40%) for up to two months. This improvement of the stability of the devices demonstrates that the well-controlled vapor deposition method allows a thorough removal of the residual solvents (i.e. DMF, DMSO et. al) and thus effectively promotes a high-quality crystallization of perovskite grains, reducing the metastable phases among the thin films.

This work was financed by Science and Technology Plan Project of Shandong Higher Education Institutions, NSFC and Open Research Fund of State Key Laboratory of Pulsed Power Laser Technology of China.