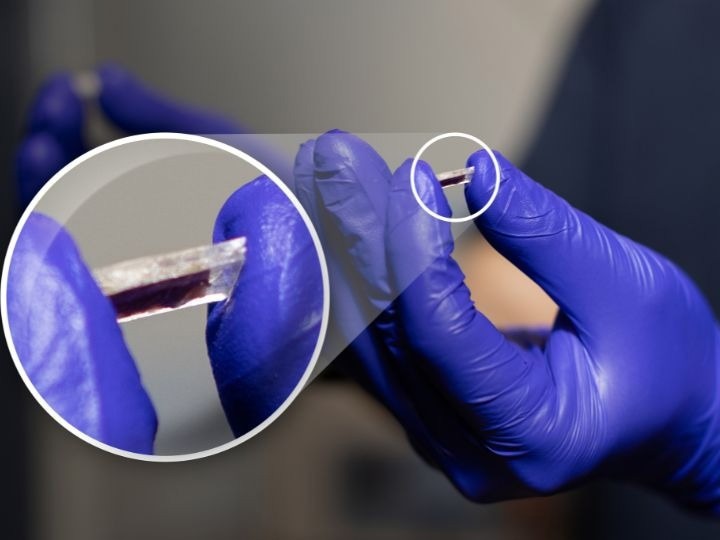

Close-up photo of the new piezoelectric sensor developed by University of Houston researchers. It can potentially work in extreme environments. Image Credit: University of Houston

For instance, in the petrochemical industry, pipeline pressures should be tracked in climates varying from hot desert heat to near-arctic cold. Numerous nuclear reactors function at a range of 300 to 1000 °C, while deep geothermal wells hold temperatures up to 600 °C.

Now, a group of University of Houston scientists have come up with a new sensor that was proven to operate in temperatures as high as 900 °C or 1,650 °F, which is known to be the temperature of volcanic lava.

Highly sensitive, reliable, and durable sensors that can tolerate such extreme environments are necessary for the efficiency, maintenance, and integrity of these applications.

Jae-Hyun Ryou, Study Corresponding Author and Associate Professor of Mechanical Engineering, University of Houston

Ryou is the corresponding author of the study reported in the Advanced Functional Materials journal.

Making It Work

Earlier, the University of Houston (UH) research team came up with III-N piezoelectric pressure sensor utilizing single-crystalline Gallium Nitride, or GaN thin films for harsh-environment applications.

But the sensitivity of the sensor reduces at temperatures higher than 350 °C, which is greater compared to those of traditional transducers made of lead zirconate titanate (PZT), but only slightly.

The group hoped the reduction in sensitivity was a result of the bandgap—the least energy needed to excite an electron and supply electrical conductivity—not being broad enough. For this hypothesis to be tested, they came up with a sensor with AlN or aluminum nitride.

The hypothesis was proven by the sensor operating at about 1000 degrees Celsius, which is the highest operation temperature among the piezoelectric sensors.

Nam-In Kim, Study First Author and Post-Doctoral Student, University of Houston

While both AlN and GaN exhibit special and outstanding properties that are ideal for use in sensors for extreme environments, the scientists were excited to determine that AlN provided a broader bandgap and also a higher temperature range.

But the team had to handle technical difficulties, including the synthesis and fabrication of the high-quality and adaptable thin film AlN.

I have always been interested in making devices using different materials, and I love to characterize various materials. Working in the Ryou group, especially on piezoelectric devices and III-N materials, I was able to use the knowledge I learned in my studies.

Nam-In Kim, Study First Author and Post-Doctoral Student working with the Ryou Group, University of Houston

In 2022, Kim earned his Ph.D. in materials science and engineering from UH. His award-winning dissertation was on adaptable piezoelectric sensors that are available for extreme surroundings and personal health care.

“It was very interesting to see the process leading to the actual results and we solved the technical challenges during the development and demonstration of the sensor,” Kim added.

What’s Next?

Currently, the scientists have been successful in illustrating the ability of the high-temperature piezoelectric sensors with AlN. They will test it additionally in harsh real-world conditions.

Our plan is to use the sensor in several harsh scenarios. For example, in nuclear plants for neutron exposure and hydrogen storage to test under high pressure. AlN sensors can operate in neutron-exposed atmospheres and at very high-pressure ranges thanks to its stable material properties.

Jae-Hyun Ryou, Study Corresponding Author and Associate Professor of Mechanical Engineering, University of Houston

The sensor’s flexibility provides extra benefits that will make it beneficial for future applications in the form of wearable sensors in personal health care monitoring products and also for use in precise-sensing soft robotics.

The scientists are looking forward to their sensor being commercially feasible.

“It's hard to put a specific date on when that might be, but I think it's our job as engineers to make it happen as soon as possible,” stated Kim.

Journal Reference

Kim, N-I., et al. (2023) Piezoelectric Sensors Operating at Very High Temperatures and in Extreme Environments Made of Flexible Ultrawide-Bandgap Single-Crystalline AlN Thin Films (Adv. Funct. Mater. 10/2023). Advanced Functional Materials. doi.org/10.1002/adfm.202370056.