Nov 7 2012

ESCATEC Design Services was given an unusual challenge. How todesign a ventilator for use when performing an operation on a patient's throat where the normal techniques of a pipe inserted into the throat would block access to the area being operated upon.

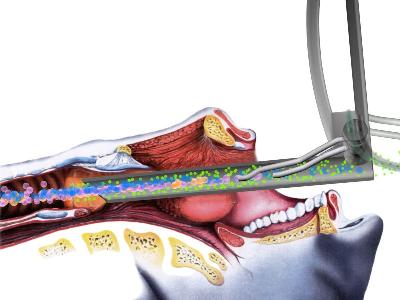

Twinstream illustration

Twinstream illustration

"Essentially the problem was how to pump air in and out of the lungs in an open system," said Peter Rossegger, CEO of Carl Reiner GMBH. "It is rather like inflating and deflating balloon with a tube into the balloon open all the time through which instruments and lasers can move. We chose ESCATEC because they could provide us with a complete solution from designing how the product would work right through to the manufacture of the final products, all conforming to the ISO standard for medical equipment - ISO13485. This is an extremely complex device that people's lives depend on, so it is vital that it designed and built to the highest standards."

The Twinstream™ Multi Mode Respirator actually has two ventilators that operate completely independently with different frequenciesand different pressures. The first provides the conventional 12 or so breaths per minute whilst the second provides a high frequency of around 800 breaths per minute. This second, high frequency ventilation reduces the stress on the lungs during lengthy operations that can take many hours, because it is very efficient at moving air in and out. This ensures that CO2 is removed more easily, and oxygen reaches deep into the lungs to be more effectively absorbed into the bloodstream.

"Designing such a device really makes you think outside the box," explained Daniel Pfeifer, Head of the Global R&D Team at ESCATEC. "You have to consider what would happen if something went wrong. If 3.5 bar of pressure was suddenly applied inside the patient's lungs, it would do tremendous damage so you have to build in all kinds of safely protocols to meet every possible 'what if' scenario. It took us a couple of years from idea to volume production. We are very proud to have designed a unique product that is saving lives on a daily basis in many leading hospitals around the world."

Martin Kingdon, Business Development Director at ESCATEC, explained, "ESCATEC is a global, contract manufacturing company with high volume production facilities in the Far East, and with the heart of its product design services in its R&D division in Heerbrugg, Switzerland. We have identified R&D as being a key differentiator for ESCATEC that sets us apart from other contract manufacturing companies. Typically, you have the design companies at one end of the product creation chain and, at the other end, you have the contract manufacturers but neither knows much about the other's skills. As a result, product prototypes are created without being designed for efficient manufacture, and when the prototype is handed over to a manufacturer they find at a late stage that the design is not optimised for mass-production. By then, it is often too late to fix it without significant cost and delay to the project. The process is not joined up! We cover the gap in the market by working in partnership with customers at every step of the way along the process to create and produce products."

Gerhard Klauser, General Manager at ESCATEC Switzerland, added, "Companies have been outsourcing their manufacturing to third parties or using Original Device Manufacturers for some time now. The trouble is that they are losing the ability to differentiate and innovate as they often don't own the all-important Intellectual Property (IP). Our end-to-end service puts the customer in control of their destiny by ensuring that they own the IP that is developed for them. This enables them to use their core knowledge and skills to come up with the product ideas that we then make real for them. It leaves them free to focus on what makes them different and unique.

"We are always looking for engineers who can work with a customer's initial idea and follow the design right through to the final product," he added. "And there is no chance of becoming bored because each project is completely unique. Designing a complex medical product like the ventilator could be followed by something as different as a military range finder or a coffee machine."