In a fuel cell, a number of thin plates are stacked close together to separate the flows of hydrogen or hydrocarbons and oxygen. Apart from the proper stacking pressure, there is a further way to affect the contact distribution within a fuel cell - applied clamping torque. A recent study, conducted by the University of Messina, Italy examines this procedure.

Challenge

There are several crucial factors that affect the design and importance of fuel cells. The uniformity of the contact pressure between the plates over a large area has to be maintained and sustained, and that is one of the vital factors. Another important factor is the elimination of parasitic leakage paths, which is essential when it comes to obtaining efficient operation.

Solution

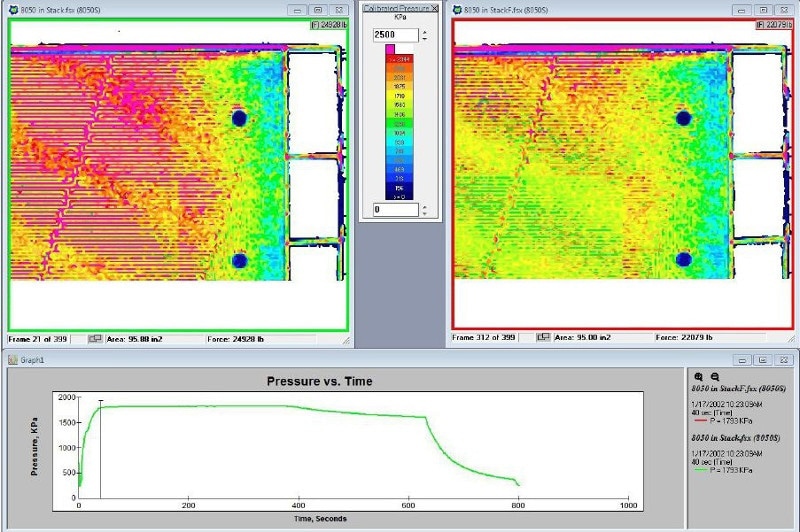

Pressure around ports and in flow field before and after pressurization.

The I-Scan™ pressure measurement system offers fuel cell manufacturers many details about how components and assembly behave. Direct comparison of the pressure patterns from different designs is possible through the data from I-Scan. Therefore, design verification becomes more time efficient, and re-engineering becomes more cost efficient.

Sensors are reusable, provide accurate pressure data, and come in different shapes and pressure ranges. With the help of Tekscan's highly qualified sales and engineering support teams, each system is configured to meet your particular needs.

Fuel Cell Pressure Measurement Applications

- Identify peak pressures, localized pressure, and spatial pressure

- Design validation testing

- R&D for new fuel cells

Benefits of Pressure Mapping

- Improve assembly technique

- Determine which materials are best for uniform contact distribution

- Improve clamping fixtures

See how Pressure Mapping Technology can be a useful tool to help validate the assembly of a product or device:

Pressure Mapping in R&D - Evaluating Component Press Fits & Seals

This information has been sourced, reviewed and adapted from materials provided by Tekscan, Inc.

For more information on this source, please visit Tekscan, Inc.