Machine vision systems are core components of many industrial applications. These systems are becoming increasingly precise and more capable of working intelligently, with ethernet-based industrial protocols such as OPC UA facilitating their direct integration into factory automation with no additional hardware or labor requirements.

The IDS NXT ocean turnkey solution includes the IDS NXT series of vision app-based, intelligent industrial cameras and is designed to meet the exacting requirements of automation engineers. Rather than just a building block, IDS NXT cameras are a key milestone for Industry 4.0 systems.

Thanks to a free software update, the embedded vision systems can be upgraded to work with OPC UA, making their AI capabilities available via a recipe collection in the network. Results are communicated directly from the field level to the machine and control level.

IDS NXT ocean: Combining AI, industrial-grade camera hardware and OPC UA. Image Credit: IDS Imaging Development Systems GmbH

IDS NXT ocean: Combining AI, industrial-grade camera hardware and OPC UA. Image Credit: IDS Imaging Development Systems GmbH

A cookbook of recipes for inference applications is not yet available in stores, but using the IDS NXT ocean’s all-in-one inference camera solution, it is possible to easily train the intelligent cameras and integrate them into factory automation.

Individually trained neural networks are immediately executable on IDS NXT cameras, which does not require any prior knowledge of artificial intelligence. The integrated OPC UA server allows inference tasks and their results to be made available to each client in the industrial network via recipe and result management tools.

The goal must be to consistently further develop industrial cameras and machine vision products for industry and make them easy to control. OPC UA paves the way for easy and fast integration of state-of-the-art technology into industrial applications.

Maximillian Keller, OPC UA Expert, IDS

Benefits of OPC UA

OPC UA is a key technology in a range of industries, facilitating the exchange of data between services, devices, and machines, even from different sectors.

The OPC UA industrial protocol is rapidly establishing itself as an open standard in Industry 4.0, thanks to features such as scalability, communication security, and vendor independence. OPC UA works via web protocols in any TCP/IP network, enabling totally platform-independent communication.

These factors have resulted in the rapid adoption of the OPC UA standard, which has been able to spread throughout and connect entire factories.

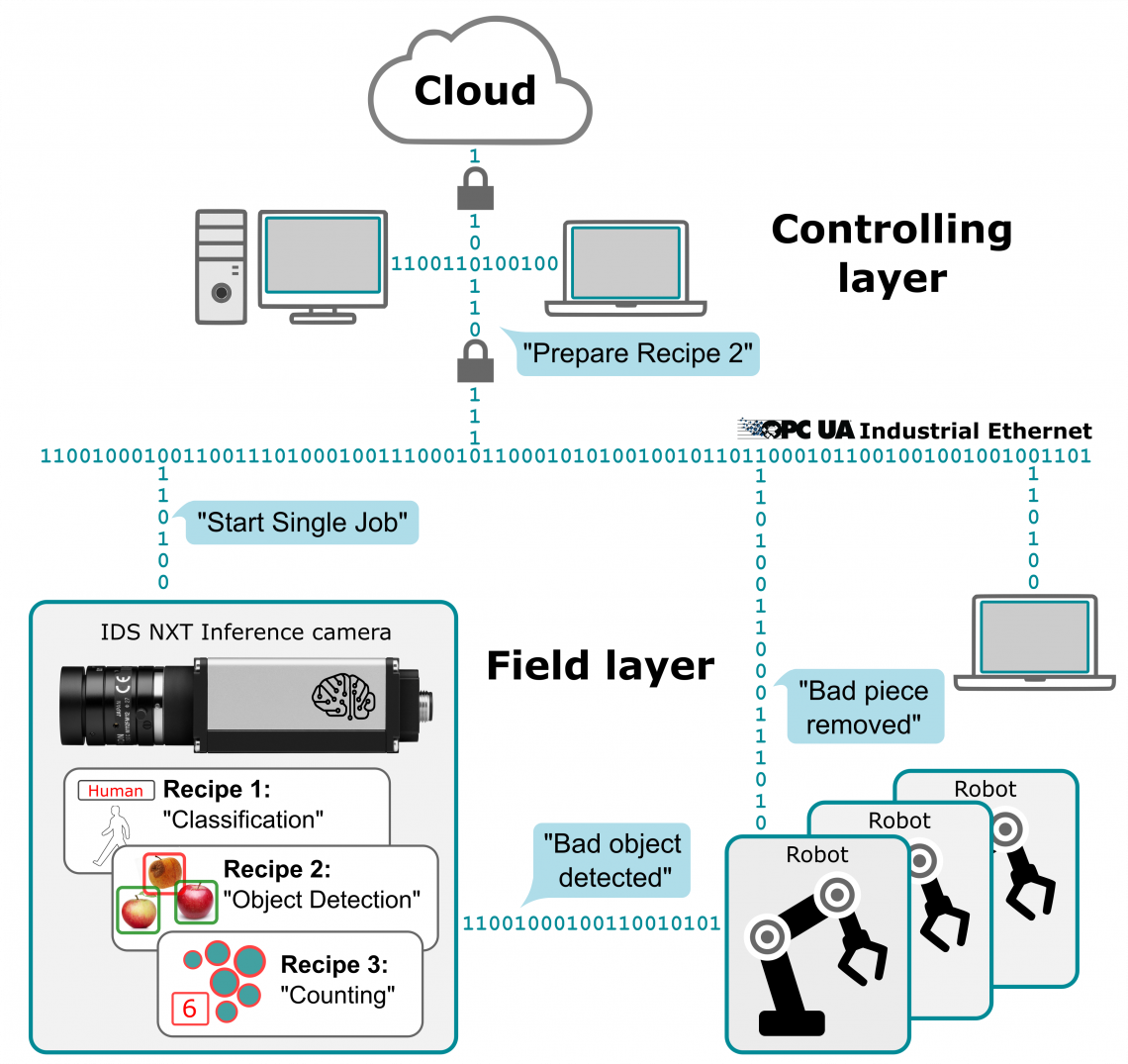

OPC UA is widely used in factory automation. Image Credit: IDS Imaging Development Systems GmbH

OPC UA is widely used in factory automation. Image Credit: IDS Imaging Development Systems GmbH

Uniform information exchange across physical layers, Ethernet-based fieldbuses, and even the cloud offers huge benefits to engineering teams because data does not have to be read, converted, and synchronized via a range of different protocols.

OPC UA unifies the language of the devices among themselves. It defines how devices describe themselves to clients and how devices describe the information and services that they provide. This means that as well as transporting machine data, this data can also be described semantically in a machine-readable form.

The industrial protocol uses companion specifications, which comprehensively describe devices of a target industry to provide a simplified, generalized view of proprietary device information. The content remains vendor-specific, however, and is treated as a black box.

The available device services (for example, complex image processing tasks in the case of IDS NXT inference cameras) will be encapsulated by OPC UA in function blocks (referred to as recipes).

The automation engineer is not required to know their exact mode of operation, but the necessary and often in-depth settings required for special applications are summarized and stored in configuration data records.

With these presets users do not have to possess in-depth knowledge of device-specific setting options, but can still optimally adjust the devices for the execution of special recipes. However, simplifying integration processes in the application workflow and making any commissioning of new devices much more straightforward.

The Self-Describing Inference Camera

Many devices and sensors provide services and information in automation and industrial IoT settings. These devices must function as servers in the OPC UA network. Depending on the information required for further processing, it may be necessary for a client to connect to a number of these servers.

Image suppliers such as industrial cameras are not typically regarded as OPC UA devices because these do not provide directly usable results or information. Intelligent cameras with independent evaluation functionality are different, however.

OPC UA is the ideal solution for embedded vision devices like IDS NXT inference cameras looking to self-describe in Industry 4.0 applications, since IDS NXT rio and rome are the first inference cameras with their own OPC UA server.

These innovative devices can function as vision sensors, with their flexible mode of operation allowing them to provide results, variable information and services in the OPC UA environment.

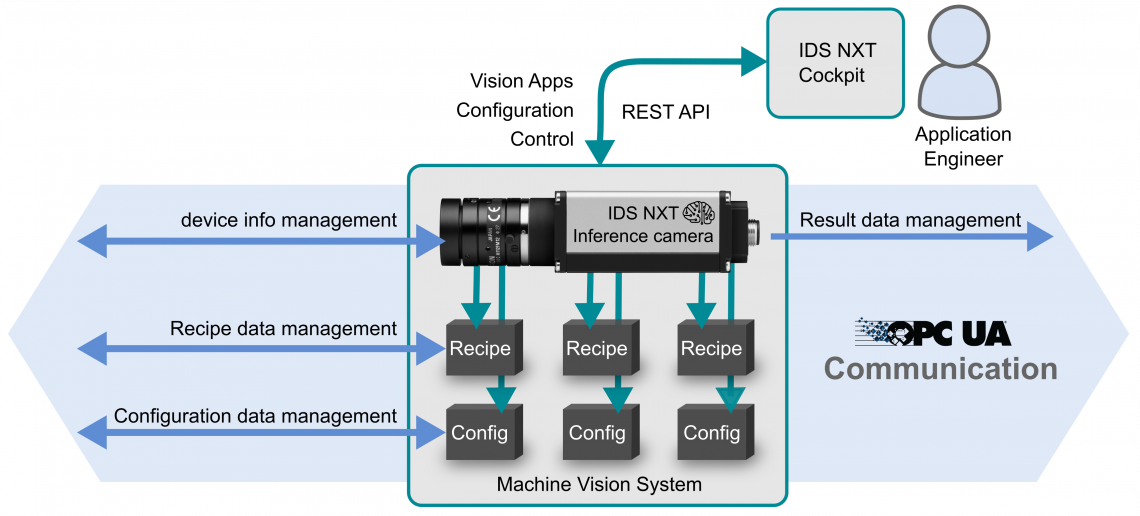

Direct integration of IDS NXT cameras via OPC UA. Image Credit: IDS Imaging Development Systems GmbH

Simple, Straightforward Product Change

The IDS NXT cameras offer image processing tasks and results via vision apps, which are as user-friendly and as easy to adjust as typical smartphone apps.

From a hardware perspective, the camera platform is supported by a parallel processing FPGA which works as an AI accelerator. It can be programmed at run-time, and is able to accelerate many existing neural network architectures.

The rapid reconfiguration afforded by the dedicated processor offers further advantages in terms of futureproofing, low recurring costs, and reduced time to market. Switching between numerous loaded CNNs can be performed at run-time, taking just a few milliseconds.

The use of the vision apps is mapped in the industrial network via OPC UA recipe and configuration management functionality, effectively enabling product change at the push of a button.

Plug and Produce

Results data and device information from an IDS NXT camera’s various vision apps is disclosed via OPC UA information models and companion specifications for machine vision systems as an object-orientated data structure. Each client can use this to acquire required information or be updated on any changes.

Uniform communication via OPC UA is the foundation for plug and produce. New devices such as IDS NXT inference cameras may be installed and used as a machine vision system in an OPC UA network with minimum effort. Commissioning time is also reduced, and there is minimum labor required for installation.

Interface Combination

The OPC UA industrial protocol and the REST (Representational State Transfer) web service offer standardized, platform-independent interfaces that enable straightforward networking with other web-enabled device classes.

This technology does not require additional software or gateways, making it an essential interface option for users looking to set up inference tasks and associated settings before making these available via OPC recipes and configurations.

The OPC UA specification does not provide function calls for device- and manufacturer-specific processes. Because image processing systems are rarely comparable in terms of their mode of operation, control, data, and settings, it is especially difficult to develop a standard without imposing limitations on the functionality of these individual systems or relying on an over-inflated generic interface.

The OPC UA specification allows device manufacturers’ unique selling points to remain viable while offering a communication protocol that remains lean and scalable.

Considering this, OPC UA is a highly suitable addition to IDS NXT cameras, ensuring easy access to camera configurations and vision app-based inference tasks in industrial environments. This information is also available in a format that is compatible and readable for OPC UA clients.

OPC UA and device-specific REST communication. Image Credit: IDS Imaging Development Systems GmbH

OPC UA and intelligent Machine Vision Applications

You have to improve the usability of the systems to make complex topics easy to master. Then the automation specialists can make the best possible use of their expertise.

Patrick Schick, Product Marketing Manager, IDS

The widespread adoption of OPC UA means that encapsulation of function blocks is also possible by means of standardized communication, finally bringing together industrial image processing and PLC.

Ensuring that the capabilities of a machine vision system are known on the network is just one step in the overall process. Once the system’s capabilities have been introduced to the network, the next step involves describing how an image should be processed. This can be a challenging task, even for automation engineers.

IDS NXT ocean is an all-in-one inference camera solution that has been developed to meet these challenges. The solution is easy to use, allowing even complex analyses to be realized without the need for specialist image processing and AI knowledge.

Working in conjunction with the IDS NXT lighthouse cloud-based software solution, this innovative software application allows images for AI-based image processing tasks to be managed with ease and allows individual neural networks to be trained within minutes.

This training process involves three simple steps:

- Upload training images in IDS NXT lighthouse

- Evaluate and label training images in line with application requirements

- Automatically train the desired network

The neural network is then ready to run on IDS NXT cameras. Users only require knowledge of their images and their application in order to set up a network that can reliably identify even highly varying objects; for example, the classification of different varieties of food products or the detection of damaged areas on fruit.

Futureproofing via Software Updates

The app-based approach utilized by the IDS NXT camera platform is as versatile as typically known from using smartphones. Recurring tasks can be set up and changed rapidly; for example, finding, measuring, counting or identifying objects; or reading codes, characters or license plates.

The availability of pre-packaged vision apps such as Object Detector and Classifier means that turnkey solutions are available to identify objects or classify image components via artificial intelligence.

Developers and AI specialists can leverage the IDS NXT Vision App Creator SDK to delve even deeper into the system, exploring its virtually endless design possibilities and application scenarios, creating individual vision apps, and customizing the functionality of IDS NXT cameras as required.

AI technology is advancing rapidly, with new architectures and frameworks added almost every month. To accommodate this rapidly developing environment, IDS is constantly developing its camera platform, providing new functionality and tools via software updates.

Thanks to that, users can continue to expand the capabilities and possibilities of IDS cameras without the need to purchase new hardware.

INFERENDUSTRY 4.0

The usability, flexibility, and expandable deployment options provided by IDS NXT inference cameras are able to provide directly actionable process decisions to an OPC UA network. This ultimately saves time and costs in terms of implementing automation solutions while ensuring rapid, straightforward integration into industrial applications.

This combination of the OPC Machine Vision Companion specification, cross-manufacturer, and cross-industry communication technology offers an ideal interface extension, allowing users to easily refine factory automation via IDS NXT embedded systems’ AI-based recipes.

There is no requirement for previous knowledge of image processing or machine learning, meaning that IDS NXT inference cameras are a true milestone for Industry 4.0.

This information has been sourced, reviewed, and adapted from materials provided by IDS Imaging Development Systems GmbH.

For more information on this source, please visit IDS Imaging Development Systems GmbH.