When working in potentially explosive atmospheres, several key factors must be considered. These include understanding the associated hazards and selecting the right tools for the designated hazardous areas.

Image Credit: dongfang/Shutterstock.com

The Cygnus 1 Ex Ultrasonic Thickness Gauge is certified as intrinsically safe for use in Zone 0 (the most hazardous classification), removing the need for Hot Work Permits. But what does that really mean? Below is an explanation of the rules and standards that govern equipment use in hazardous environments.

Explosive Atmospheres

The term "Ex" is recognized globally in reference to explosive atmospheres and the systems designed to prevent explosions.

Hazardous Areas are locations where there is a risk of fire or explosion due to the presence of flammable or ignitable substances in the air. These substances include gases, vapors, and dust (in concentrations high enough to form an ignitable mixture).

Ex Schemes and Standards Worldwide

The International Electrotechnical Commission (IEC) sets international standards for classifying Hazardous Areas and Ex-rated equipment, along with a standard labelling system.

The IEC standard is endorsed by the United Nations and provides a shared basis for understanding the different Ex rating systems used globally. The IECEx system is the IEC’s certification program for equipment used in explosive environments.

A map by Mirko Torrez Contreras (2021) shows which countries follow which schemes and standards. Ex systems are used worldwide, most of which are based on the IECEx model.

Image Credit: Reference source: Mirko Torrez Contreras (2021), digital image, https://www.linkedin.com/pulse/too-brief-history-origins-ex-standards-part-iii-iecex-mirko/

Regions such as the European ATEX Standard and the North American NEC/UL Standards utilize the IEC 60079 Standard as a source.

Source: Cygnus Instruments Limited

| |

|

| NEC / UL Scheme (North America) |

UL 60079 |

| ATEX scheme (European) |

EN 60079 |

| UKEX Scheme (United Kingdom) |

BS EN 60079 |

| INMETRO Scheme (Brazil) |

EN 60079 |

The Cygnus 1 Ex Gauge has been approved to IECEx, ATEX, and UKEX requirements and is the only gauge that meets the highest classification of ATEX Zone 0, which is equivalent to NEC (UL) Class I Division 1 Group “ALL.”

Zones and Divisions

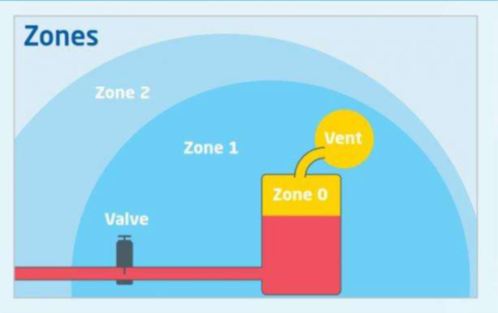

Zones and Divisions refer to hazardous area classifications.

- "Zones" is the terminology used in the European ATEX scheme.

- "Classes," "Divisions," and "Groups" are terms used in the North American NEC/UL system.

In both the IECEx and ATEX systems, hazardous areas are classified into Zones based on the frequency and duration of the presence of an explosive atmosphere.

- Zone 0 is an area in which an explosive gas atmosphere is continuously present or present for long periods.

- Zone 1 is an area where an explosive gas atmosphere is likely to occur during normal operation.

- Zone 2 is an area in which an explosive gas atmosphere is not likely to occur during normal operation, and if it does, it will exist only for a short time.

Image Credit: Cygnus Instruments Limited

Zone 0 is the most hazardous area.

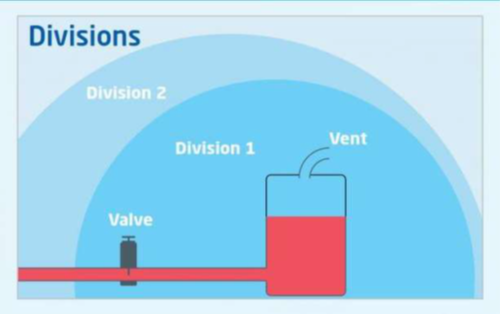

In the North American NEC/UL Ex scheme, Divisions are used instead of Zones.

- Division 1 = Zone 0, Zone 1

- Division 2 = Zone 2

Image Credit: Cygnus Instruments Limited

Plants and facilities may contain multiple Zones or Divisions. Once these hazardous areas are defined, appropriate signage must be installed to warn and inform anyone entering the area.

It’s important to note that these area classifications can change, especially as a result of a leak. For example, if a welded joint, flange, or valve leaks, the surrounding area may be reclassified from Zone 1 to Zone 0.

Image Credit: Cygnus Instruments Limited

Ex Standards vs. Other Testing Methods

There are various methods for testing equipment in hazardous areas, but it is important to understand how they differ from Ex standards.

The MIL-STD-810G standard tests equipment to determine if it could cause an explosion at the time of testing. However, it does not account for real-world use, being dropped, developing faults, or battery short-circuits. As a result, it does not guarantee that the equipment will remain safe under typical operating conditions.

In contrast, Ex standards are designed to ensure that equipment (even in the case of failure) cannot cause an explosion. Equipment certified to Ex standards must be designed to be safe.

Redundant safety circuits are built into the design so that if one fails, another continues to provide protection. Equipment is also tested for drops, ingress protection (IP), and battery short-circuiting to verify that it will not explode or overheat. Materials must be anti-static to prevent static charge buildup that could lead to ignition.

The table below outlines the key differences between Ex standards and MIL-STD-810G.

Source: Cygnus Instruments Limited

Ex to ISO 60079

IECEx / ATEX / UKEX / INMETRO / NEC-UL |

MIL-STD-810G

Method 511.5, Procedure I. |

| Equipment must be safe by design. |

This is a simple test done in an explosive atmosphere. The test operates equipment in a 4 % n-Hexane fuel/air mix to see if it causes an explosion. |

| A notified body examines the equipment and issues an Ex Certificate if standards are met. It is legally binding. Equipment manufacturers are regularly audited to ensure compliance. |

This is NOT an Ex Certification (no certificate), and the equipment is NOT Ex certified. |

| An EPL is stated to clarify which zones it can be used in. |

The equipment CANNOT be taken into an Ex zone. |

| Multiple fault conditions are applied and considered. It requires the use of redundant safety circuits. |

NO fault conditions are applied.

NO battery sparks are considered.

NO drop testing is done.

Static electrics build up is NOT considered. |

Intrinsically Safe vs. Explosion-Proof

Intrinsically safe is one of the protection concepts used to define Ex equipment designed for safe operation in hazardous areas.

The Cygnus 1 Ex gauge uses intrinsic safety protection to limit the energy within its system, ensuring it is too low to ignite a hazardous atmosphere under any conditions—including low power levels and low stored energy. Intrinsically safe equipment can be Ex-certified for Zones 0, 1, or 2.

Another common concept is ‘explosion-proof’ (or ‘flame-proof’). This type of equipment is sealed and rugged to prevent the ignition of a hazardous atmosphere. However, a spark or explosion can still occur inside the device.

For this reason, explosion-proof equipment can only be certified for Zones 1 or 2. Only intrinsically safe equipment is approved for use in Zone 0.

Understanding Equipment Protection Levels (EPLs)

All certified Ex equipment (portable or fixed) intended for operation in hazardous areas will possess an Ex Certificate of Conformity (C-of-C) that specifies its Equipment Protection Level (EPL), denoted by a ‘G’ code.

The table below illustrates the correlation between Zones, EPLs, and different protection concepts. Cygnus uses the intrinsically safe protection type for its Ex products.

Source: Cygnus Instruments Limited

Type of Protection/

Protection Concept |

Zone |

| 0 |

1 |

2 |

| Equipment Protection Level ‘EPL’ |

| Ga |

Gb |

Gc |

| Intrinsically Safe* |

|

|

|

| Encapsulation |

|

|

|

| Flame-proof / Explosion-proof |

|

|

|

| Oil Filled |

|

|

|

| Pressurised |

|

|

|

| Sand Filled |

|

|

|

| Hermetically Sealed |

|

|

|

*Portable electronic equipment such as phones, torches, cameras, and instrumentation will use the Intrinsically Safe protection concepts.

Cygnus 1 Ex Does Not Require a Hot Work Permit

Hot Work Permits are used to reduce the risk of tools or equipment generating sparks or enough heat to ignite gases in hazardous areas.

Thanks to its intrinsically safe design, the Cygnus 1 Ex gauge does not generate enough energy to ignite an atmosphere and can be used safely in hazardous zones without the need for a Hot Work Permit.

This avoids the often time-consuming and costly process of obtaining a permit, which typically requires:

- Authorization from a senior person

- Gas level checks by a qualified individual

- Continuous monitoring of oxygen and flammable substances

- Personnel trained in emergency response and first aid

- Specialist rescue equipment on standby

- Purging of pipes or tanks with nitrogen

- Suspension of plant operations

Hot work permits can present significant challenges and necessitate careful planning. Utilizing Ex equipment can streamline this process.

The Cygnus 1 Ex is the world’s only Zone 0 UTM gauge certified to ATEX, IECEx, and UKEX for use in Zones 0, 1, and 2. It features three measuring modes and includes a Deep Coat function, which allows accurate measurements through coatings up to 20 mm.

The gauge also offers A-Scan and B-Scan capabilities for additional measurement verification and cross-sectional display. Its data logging function records measurements along with A-Scans for straightforward analysis and reporting.

For more complex applications, Manual Measurement Mode allows users to adjust gates and gain as needed.

When paired with Cygnus’ High-Temperature Ex probe, the gauge becomes a high-temperature thickness gauging kit, enabling effective corrosion inspection of hot assets in service without necessitating a plant shutdown or hot work permit.

Despite its advanced features, the Cygnus 1 Ex gauge is user-friendly, offering four measurement screens, four function keys for straightforward control, and an intuitive menu. As with all Cygnus products, the Cygnus 1 Ex thickness gauge is manufactured in the UK and comes with a three-year warranty.

This information has been sourced, reviewed and adapted from materials provided by Cygnus Instruments Limited.

For more information on this source, please visit Cygnus Instruments Limited.