Oil rigs, gas plants, underground mines, and firegrounds are classified as high-risk environments due to frequent hazards, including heat, explosions, crush or fall injuries, and exposure to dangerous gases. Gases present a serious safety threat, as flammable or toxic compounds can quickly reach life-threatening levels in confined, poorly ventilated areas. Measuring these gases is therefore essential to protecting workers.

Image Credit: Hamamatsu Photonics Europe

Conventional fixed gas monitoring systems are not always practical, particularly when personnel are constantly moving or working in remote areas. This has sparked a growing shift toward wearable and handheld gas sensors designed to clip onto clothing or fit into a pocket, delivering real-time alerts that warn workers of potential danger.1,2

These devices are increasingly regarded as essential personal protective equipment (PPE), particularly in fields where exposure to methane (CH4), carbon monoxide (CO), or volatile organic compounds (VOCs) poses serious risks.3 Despite their small size, they must also offer high sensitivity and long battery life, as they are frequently used in settings where access is limited and maintenance is not always practical.

This article explores how optical sensing technologies – especially non-dispersive infrared (NDIR) systems sensing in the mid-infrared (MIR) range – enable the development of compact, dependable gas sensors for harsh industrial conditions.

Hazardous Gas Examples

Hazardous gases typically found in high-risk environments can be grouped into asphyxiants, toxic gases, and flammable gases.

Asphyxiants are gases that displace oxygen in air, leading to suffocation, and include CO, CH4, and nitrogen (N2). Toxic gases – such as carbon dioxide (CO2), hydrogen sulfide (H2S), and chlorine (Cl2) – can cause severe health effects or even death upon inhalation. Propane (C3H8), gasoline (C8H18), and CH4 can cause fires and explosions at sufficiently high concentrations.2

An Optical Approach

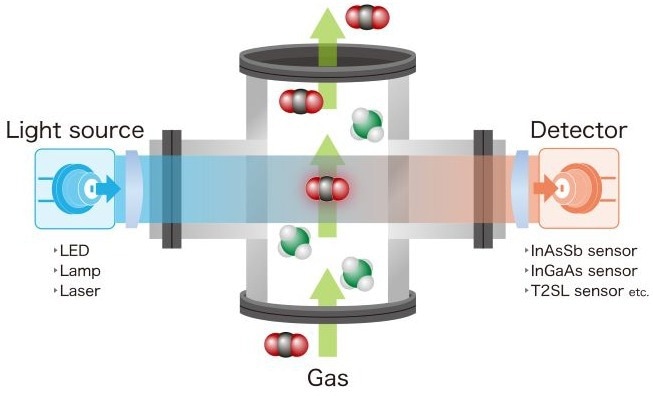

NDIR sensing technologies utilizing the MIR range are widely deployed for mobile gas detection. These systems direct infrared light through a gas and measure absorption at specific wavelengths. A MIR LED typically emits the light, while a photodetector on the other side of the gas path measures the remaining light intensity. The difference between emitted and detected light determines the amount of gas present.

Many hazardous gases absorb IR light in distinct spectral bands, allowing NDIR systems to detect them with high selectivity. This method is especially effective for detecting gases such as CO2, CH4, C3H8, and other hydrocarbons, all with strong absorption in the MIR range.4 However, homonuclear molecules such as N2 and Cl2 do not exhibit strong absorption in the IR region and therefore cannot be detected using NDIR sensing.

Figure 1. A schematic of a gas sensor. Image Credit: Hamamatsu Photonics Europe

Small Devices, Big Challenges

A key advantage of MIR NDIR sensors is that they do not depend on consumable materials. NDIR units employ solid-state components – such as IR LEDs and photodiodes that are spectrally matched to the emitted light – and do not depend on chemical reactions that degrade over time.

Consequently, NDIR sensors can maintain precise, drift-free performance for more than 10 years with minimal maintenance. In contrast, electrochemical sensors have shorter lifetimes, require frequent calibration, and experience sensor drift, particularly in long-term, low-maintenance deployments.4,5

Achieving dependable gas detection in a device small enough to be worn requires smart engineering. Although many commercially available sensors are currently shorter than 20 mm, they still satisfy stringent requirements such as the ATEX (ATmosphères EXplosibles) directive and the IECEx (International Electrotechnical Commission Explosive) scheme for explosive atmospheres, as well as performance standards such as IEC 60079-29-1 and EN 45544. These standards cover the detection of flammable, toxic, and asphyxiant gases in industrial environments.

The sensors must consume low power and maintain high sensitivity, often relying on precisely tuned MIR sources and detectors to provide consistent, interference-resistant measurements with minimal servicing.

To accomplish this, many high-performance MIR NDIR designs employ MIR LEDs combined with indium arsenide antimonide (InAsSb) photodiodes. This pairing is particularly effective because the LED emission spectra can be selected to match the absorption peaks of target gases such as CH4, C3H8, and CO2. InAsSb photodiodes are highly sensitive in the 3-5 μm spectral range and beyond, matching the emission wavelengths of the target molecules.

This strong spectral overlap guarantees accurate detection of even low gas concentrations, with minimal interference from environmental factors such as humidity or temperature fluctuations.6,7 These solid-state components are compact and energy efficient, making them ideal for long-term field use.

However, these benefits come with trade-offs. In applications prioritizing cost or simplicity, some manufacturers opt for pyroelectric detectors, lead salt sensors, or filament-based emitters such as tungsten lamps. These components reduce manufacturing expenses but tend to be slower and/or less precise, making them more appropriate for lower-end or less demanding deployments.

Table 1. Infrared absorption peaks of hazardous gases. Source: Hamamatsu Photonics Europe

| Molecule |

Absorption in IR (μm) |

| CO2 |

4.26 |

| CH4 |

3.30 |

| CO |

4.60 |

| H2S |

2.60, 7.90 |

| C3H8 |

3.37, 7.25 |

| C8H18 |

3.40, 6.80,-7.30 |

Due to their flammability risk, most portable devices are currently optimized for single-gas detection, typically methane. While multi-gas sensors exist, they usually require additional optical channels, filters, or detectors, resulting in increased complexity, size, and cost. Engineers must, therefore, balance multiple constraints such as form factor, power budget, sensitivity requirements, and price point to select the right design.

Summary

Portable gas sensors are quickly becoming essential to everyday safety equipment in high-risk industries. Thanks to MIR LEDs and InAsSb photodiodes developments, today’s NDIR-based sensors provide selective, reliable gas detection in a device small enough to fit into a pocket. These compact systems are robust, low-power, and capable of operating for years with low maintenance. They are well-suited for frontline workers in the oil and gas, mining, and emergency response fields.

Hamamatsu continues to drive these advancements by enhancing sensitivity, reducing detector power consumption, and utilizing non-hazardous materials to ensure safer, more sustainable designs. As development continues, customers can expect even smarter, more efficient sensors that prioritize safety, wherever the application may be.

References and Further Reading

- United Safety (2025). Fixed vs. Portable Gas Detection: Which One Do You Need? | United Safety. (online) United Safety. Available at: https://www.unitedsafety.net/uslblog/2025/03/fixed-vs-portable-gas-detection-which-one-do-you-need.

- Environmental XPRT. (2023). Unveiling The Importance Of Portable Gas Detectors. (online) Environmental-expert.com. Available at: https://www.environmental-expert.com/articles/unveiling-the-importance-of-portable-gas-detectors-1132294.

- Sensor One Stop. Infrared (NDIR) Sensors, A Comprehensive Guide. Available at: https://sensor1stop.com/wp-content/uploads/2025/05/Infrared-NDIR-Sensors-A-Comprehensive-Guide.pdf.

- Hamamatsu Photonics. (2015). Beyond Gas Sensing Panel Discussion | Hamamatsu Photonics. (online) Available at: https://www.hamamatsu.com/eu/en/resources/webinars/infrared-products/beyond-gas-sensing-panel-discussion.html.

- Hamamatsu Photonics. (2025). Gas analysis | Hamamatsu Photonics. (online) Available at: https://www.hamamatsu.com/eu/en/applications/measurement/gas-analysis.html.

- Hamamatsu Photonics. NDIR gas sensing Improve your detector design | Hamamatsu Photonics. (online) Available at: https://www.hamamatsu.com/content/dam/hamamatsu-photonics/sites/documents/21_HPE/featured-products-and-technologies/mid-ir-leds-for-ndir-gas-sensing.pdf

- Hamamatsu Photonics. (2015). Beyond Gas Sensing Panel Discussion | Hamamatsu Photonics. (online) Available at: https://www.hamamatsu.com/eu/en/resources/webinars/infrared-products/beyond-gas-sensing-panel-discussion.html.

This information has been sourced, reviewed and adapted from materials provided by Hamamatsu Photonics Europe.

For more information on this source, please visit Hamamatsu Photonics Europe.