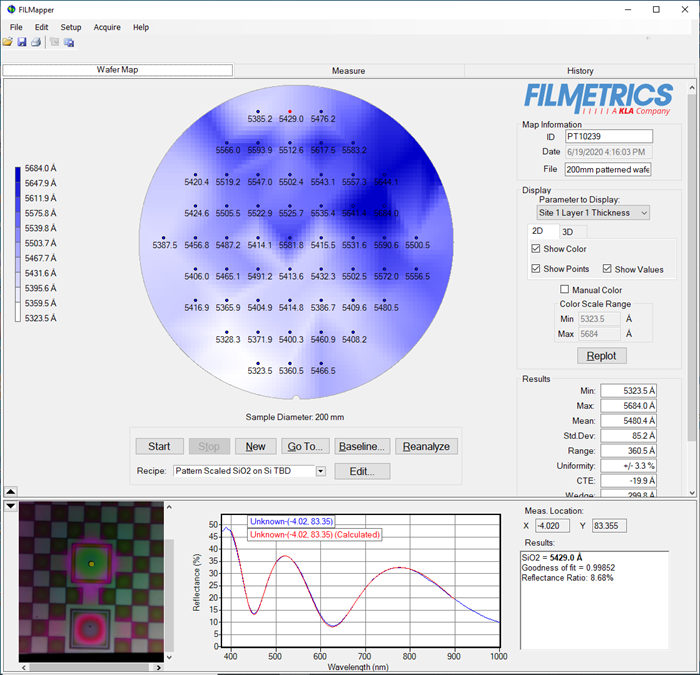

The F54-XY advanced spectral reflectance device allows for the easy mapping of thin-film thickness on samples up to 300 mm. The F54-XY-200 configurations measure samples up to 200 mm using a motorized X-Y stage that moves automatically to predefined measurement positions, allowing for thickness measurements as fast as two points per second.

The F54-XYT-300 configuration has an extra high-performance rotary stage that supports measurements on 300 mm wafers.

With the automated film thickness mapping system, users can choose from hundreds of standard polar, rectangular, or linear map patterns or design their own with an unlimited number of measurement points. Pattern recognition software enables the measurement of both patterned and unpatterned samples.

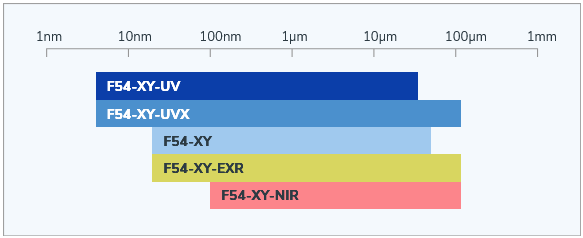

The F54-XY variants differ largely in terms of film thickness and wavelength range. Shorter wavelengths (e.g., F54-XY-200-UV) are often required for measuring thinner films, but longer wavelengths can be used to measure thicker, rougher, or more opaque films.

Image Credit: KLA Instruments™

Model Specifications

Source: KLA Instruments™

| Model |

Thickness Range* |

Wavelength Range |

| F54-XY |

20 nm - 50 µm |

380-1050 nm |

| F54-XY-UV |

4 nm - 35 µm |

190-1100 nm |

| F54-XY-NIR |

100 nm - 120 µm |

950-1700 nm |

| F54-XY-EXR |

20 nm - 120 µm |

380-1700 nm |

| F54-XY-UVX |

4 nm - 120 µm |

190-1700 nm |

*Material and objective dependent

Thickness Measurement Range

Image Credit: KLA Instruments™

F54-XY Options

- NIST-Traceable Thickness Standard

- High-Pass Filter Wheel

- Pattern Recognition Software

- Motorized Turret

What is Included

- SiO2 on Si Thickness standard

- Integrated spectrometer/light source unit

- Integrated on-board Silicon reflectance standard

- FILMapper measurement software

- Vacuum pump

Additional Perks

- Online “Hands On” support

- Library with over 130 materials included with every system, as well as access to hundreds more

- Applications Engineers are ready for immediate 24-hour help (Mon-Fri)

Common Optional Accessories

NIST-traceable thickness standard. Image Credit: KLA Instruments™