In thermal analysis, differential scanning calorimeters (DSCs) are scientific devices that measure the energy a sample absorbs or releases during heating or cooling.

Researchers, scientists, and engineers in various industries use them to precisely measure and analyze thermal effects like melting, crystallization, and glass transitions.

METTLER TOLEDO DSC instruments, with their sophisticated features and capabilities, offer precise and dependable results that are essential for the creation, production, and quality assurance of a variety of materials.

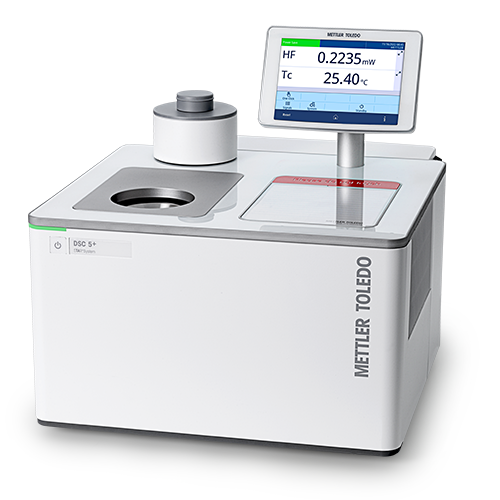

Differential Scanning Calorimeter DSC 5+ from METTLER TOLEDO

Video Credit: Mettler Toledo International

Products

Thermal Analysis System DSC 5+

The DSC 5+ establishes a new benchmark by providing a more effective and high-performing DSC.

Image Credit: Mettler Toledo International

Thermal Analysis System DSC 3

Differential Scanning Calorimetry for routine analysis

Image Credit: Mettler Toledo International

Discover the Next Generation of Performance with the DSC 5+

- High-sample throughput (96 samples and 7 references)

- Power Compensation and Heat Flux modes

- Guaranteed repeatable results, regardless of operators

- MMS 1 Sensor: 136 TC, 2 heaters for Power Compensation

- Fully modular and upgradable solution

Benefits of the DSC Instruments

Exceptional Sensitivity

The MMS 1 (MultiSTAR™) sensor's advanced two-layer design, incorporating up to 136 thermocouples, delivers unparalleled sensitivity for DSC. Its outstanding signal-to-noise ratio enables the detection of even the weakest thermal effects, ensuring precise and reliable results.

- Detects weak thermal effects

- Up to 136 Thermocouples

Outstanding Resolution

Achieve unparalleled clarity in material analysis with the MMS 1 sensor. Its remarkably short signal time constant enables ultra-fast enthalpy measurements, allowing for significantly improved resolution of closely spaced thermal transitions.

- Short signal time constant

- Distinguishes closely spaced effects

Flat Baselines

The groundbreaking sensor technology, featuring a revolutionary star-shaped thermocouple arrangement, effectively compensates for temperature gradients. This ensures exceptionally flat baselines and highly reproducible measurement results.

- Enhanced reproducibility

- Accurate measurements

Power Compensation DSC

Customers can select power compensation and heat flux modes using the most recent cutting-edge sensor technology.

Two heaters built into the sensor, one beneath the sample and one beneath the reference, allow the single-furnace power compensation mode. If the sample undergoes an enthalpy change during a measurement, the suitable heater will compensate for the temperature difference between the sample and reference (ΔT) until ΔT = 0.

A heat flow signal with exceptional resolution and separation of close-lying thermal effects results from the extremely accurate measurement of the amount of heat power added to equalize ΔT.

Image Credit: Mettler Toledo International

Versatile Modularity

Future-proof DSC analysis with a modular thermal analysis system, ensuring flexibility in configuring the setup according to specific requirements.

People can select what suits them best, ranging from a basic gadget to a fully automated system with a sample robot and time-saving software options. If a customer needs a change, it is simple to implement updates and upgrades whenever they want.

The modularity and upgradeability of cutting-edge instrument solutions will protect user's valuable investment

Image Credit: Mettler Toledo International

Increased Productivity

Perform More Experiments in a Shorter Time, Using Less Resources

Cutting-edge hardware and software automation solutions make the entire differential scanning calorimeter analysis workflow more efficient. The 3-axis sample robot with a gas-purged sample chamber can handle up to 96 samples and seven reference crucibles for 24-hour operation. The software automation solutions save time and effort by streamlining measurement interpretation, sample processing, and result evaluation.

Save important operator time, use fewer resources, and get repeatable DSC analysis results.

TA Sample Robot: High-Capacity Automation with an Environmentally-Controlled Crucible Chamber

Video Credit: Mettler Toledo International

Common DSC Applications

Differential Scanning Calorimetry (DSC) is widely utilized across various fields:

- Thermal analysis of polymers

- Heat capacity

- Glass transition

- Oxidation induction time (OIT) and Oxidation onset temperature (OOT)

- Polymer crystallization

Image Credit: Mettler Toledo International

Compare DSC 3 and DSC 5+

Source: Mettler Toledo International

| DSC 3 |

DSC 5+ |

|

|

| Sensors |

| FRS 5+ HSS 8+ |

MMS 1 |

| Number of thermocouples |

| FRS: 56 HSS: 120 |

136 |

| Resolution (heat flow) |

| FRS: ++ HSS: + |

+++ (in power compensation mode) |

| Sensitivity (heat flow) |

| FRS: + HSS: +++ |

+++ |

| Reproducibility (enthalpy) |

| + |

+++ |

| Heat flow calibration and adjustment |

| Reference materials |

Automatic electrical calibration (up to 10 reference points) |

| Cp accuracy |

| + |

+++ |

| Enthalpy accuracy |

| + (Reference materials) |

++ (Electrical adjustment) |

| Measurement mode(s) |

| Heat flux only |

FlexMode™: Power compensation and heat flux |

| Automation capabilities (sample robot) |

- 34 sample positions

- Universal crucible gripper (20-100 µL)

- Optional lid-piercing

- Manual exchange of reference crucible

- Manual crucible tray cover

- Manual crucible disposal

|

- 96 sample and 7 reference positions

- Universal crucible gripper (20-100 µL)

- Lid-piercing included

- Automatic exchange of reference crucible

- Gas-purged crucible chamber with automated cover

- Automated crucible disposal

|

| Automation capabilities (STARe software) |

- EvalMacro auto-evaluation

- AIWizard™ auto-evaluation plus interpretation

- Time-saving FlexCal™ adjustment

|

- EvalMacro auto-evaluation

- AIWizard™ auto-evaluation plus interpretation

- Time-saving FlexCal™ adjustment

|

| Gas management |

| MFC up to 3 gases (option) |

MFC up to 4 gases (included) |