Thermomechanical analysis (TMA) measures a material's dimensional changes as a function of temperature, including expansion coefficients, softening temperatures, and relaxation effects that other thermal analysis techniques may not detect.

METTLER TOLEDO TMA instruments provide a broad temperature range, multiple deformation modes for various sample types, SDTA for simultaneous thermal effect measurement, and advanced automation. These cutting-edge features guarantee precise and efficient analysis for both industry and research.

TMA/SDTA 2+

Discover how advanced Swiss technology elevates measurement capabilities to the next level.

Thermomechanical analyzer (TMA) from METTLER TOLEDO

Video Credit: Mettler Toledo International

Products

TMA/SDTA 2+ Instrument

The integration of TMA and SDTA in a single instrument delivers valuable insights into materials' dimensional changes and heat flow. Ideal for films, coatings, fibers, cylinders, polymers, crystals, and more, it strengthens advanced research and quality control in material characterization.

Image Credit: Mettler Toledo International

TMA-Sorption Interface

The TMA-Sorption system allows for analyzing material behavior under controlled temperature and relative humidity conditions. This accessory is essential for studying the impact of moisture content on various materials.

Image Credit: Mettler Toledo International

TMA Sample Robot with Quartz

The TMA sample robot offers 20 sample positions for precise measurements up to 1100 °C. Designed for use with quartz sample holders, this setup ensures that the measurement path contains only the sample centered between a single material type, guaranteeing maximum accuracy and consistency.

Image Credit: Mettler Toledo International

TMA Sample Robot with Ceramic

The TMA sample robot offers 20 sample positions for precise measurements up to 1600 °C. Designed for ceramic sample holders, this setup ensures that the measurement path contains only the sample centered between a single material type, guaranteeing maximum accuracy and consistency.

Image Credit: Mettler Toledo International

Wide Temperature Range

Leveraging innovative technology, METTLER TOLEDO’s thermomechanical analyzers deliver unmatched efficiency and reliability. With a broad temperature range from -150 to 1600 °C and SDTA for simultaneous thermal effect measurement, they are the ideal tools for gaining critical insights into material behavior.

Image Credit: Mettler Toledo International

SDTA – For Simultaneous Measurement of Thermal Effects

- SDTA enables the simultaneous measurement of thermal effects in a sample during TMA analysis. This integrated approach enhances accuracy and helps identify melting, crystallization, and chemical reactions.

- In METTLER TOLEDO instruments, the SDTA signal is derived from the difference between the measured sample temperature and the reference temperature, calculated using a patented model.

- METTLER TOLEDO is the only manufacturer to position the thermocouple in close proximity to the sample, ensuring precise temperature measurement and a deeper understanding of thermal effects.

Image Credit: Mettler Toledo International

The Unique TMA Sample Robot

A New Level of Efficiency

Unlock the full potential of METTLER TOLEDO TMA/SDTA with the innovative and exclusive sample robot. This highly versatile automation system provides 20 sample positions for seamless, uninterrupted productivity. Simply prepare the samples in the patented sample holders, place them on the specially designed sample tray, and let it run.

TMA Automation: Free up Operator Time

Video Credit: Mettler Toledo International

METTLER TOLEDO is the only manufacturer to offer this unique automation solution for TMA on the market.

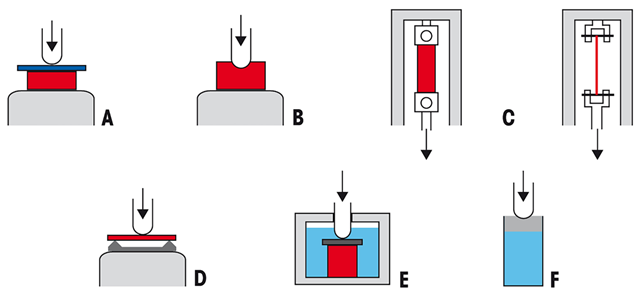

Deformation Modes for Different Types of Samples

METTLER TOLEDO TMA/SDTA instruments feature a range of accessories that allow for measuring samples in various sizes and deformation modes. The optimal mode for the specific application depends on the sample's shape, properties, and the required information.

Image Credit: Mettler Toledo International

- Compression/Dilatometric Mode

- Penetration Mode

- Tension Mode – Ideal for films and fibers

- 3-Point Bending Mode

- Swelling in a Liquid

- Volume Expansion of a Liquid

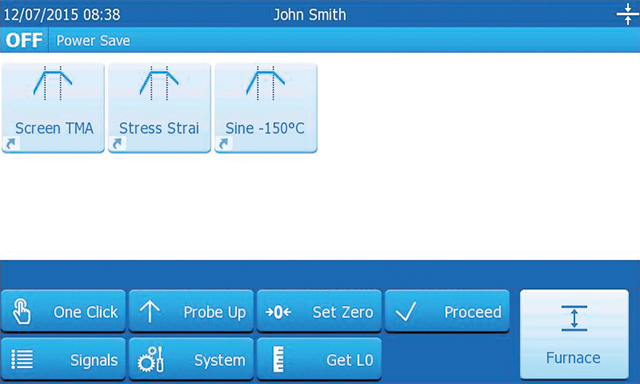

Start the Experiments with Just One Click™

The exclusive One Click™ function enables quick and easy execution of predefined methods directly from the TMA/SDTA touchscreen display. This streamlines routine and repeats measurements, ensuring fast processing and accurate method selection every time.

Image Credit: Mettler Toledo International