This completely integrated system provides label verification, weight control, and a completeness check for all product shapes. The space-saving approach, which can be entirely customized from standardized components, provides advanced quality control.

Prevent Recalls and Reduce Waste

Identify products that are under- or overfilled to minimize waste and adhere to weighing standards. Examine quality flaws and label data to avoid recalls.

Small Footprint

The single frame with only four feet on the ground saves considerable space. Sharing handling parts and conveyor belts decreases costs.

Lower Total Cost of Ownership

Take advantage of a single service specialist for both technologies, a single partner for selection and configuration, and one comprehensive training program.

Features

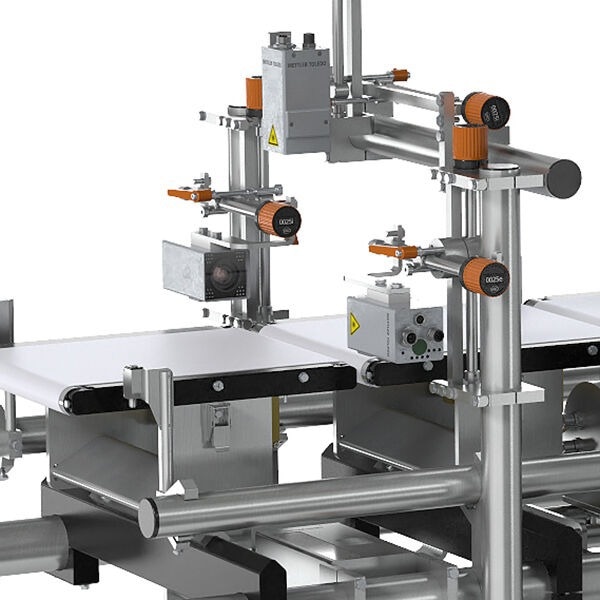

Flexible System Design

Customize the system components to suit application requirements. Choose from standardized checkweighers and vision inspection systems to develop the optimal combination for the production challenges.

Image Credit: Mettler Toledo - International

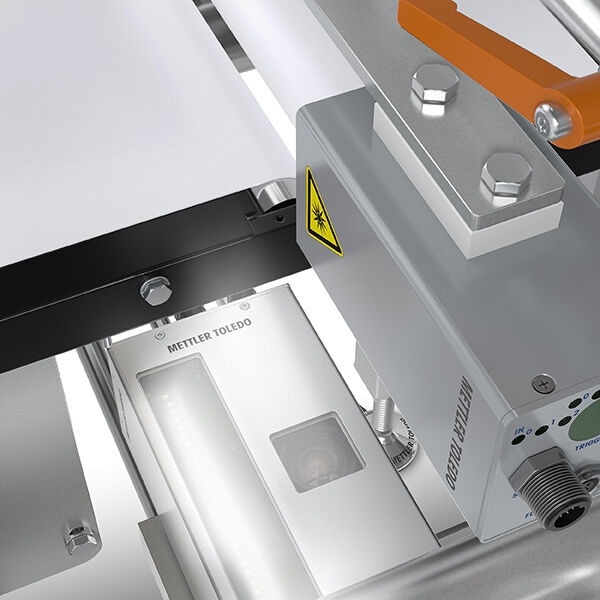

Weight and Completeness Control

The C-Series checkweighers provide accurate weighing at up to 800 ppm production speeds, utilizing FlashCellTM EMFR technology to ensure 100% weight control. They effectively sort out underfilled or incomplete products, aiding in compliance with weighing regulations.

Image Credit: Mettler Toledo - International

Label Data and Quality Control

Select from a range of vision inspection systems to conduct 100% automated label inspections for all product shapes. Early verification of label data and quality in the production process helps to prevent recalls, avoid costly retailer fines, and minimize waste.

Image Credit: Mettler Toledo - International

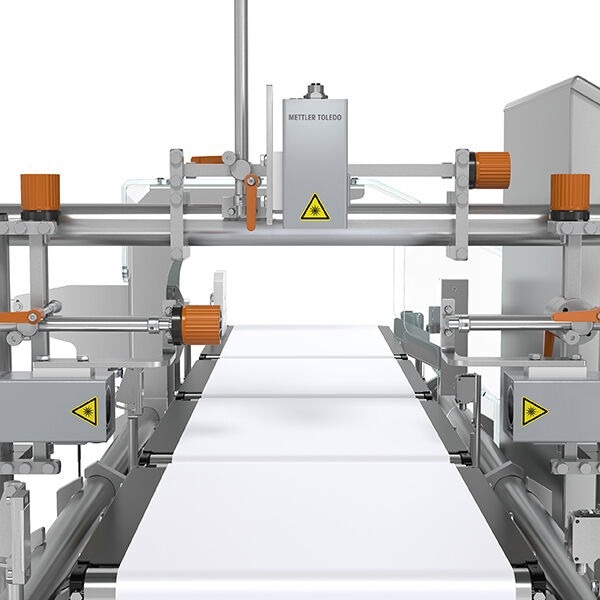

Product Handling Excellence

Maximize process stability and equipment efficiency for label and weight inspection by utilizing a wide range of shared transition, transport, stability, and sorting options suitable for any packaging format.

Image Credit: Mettler Toledo - International

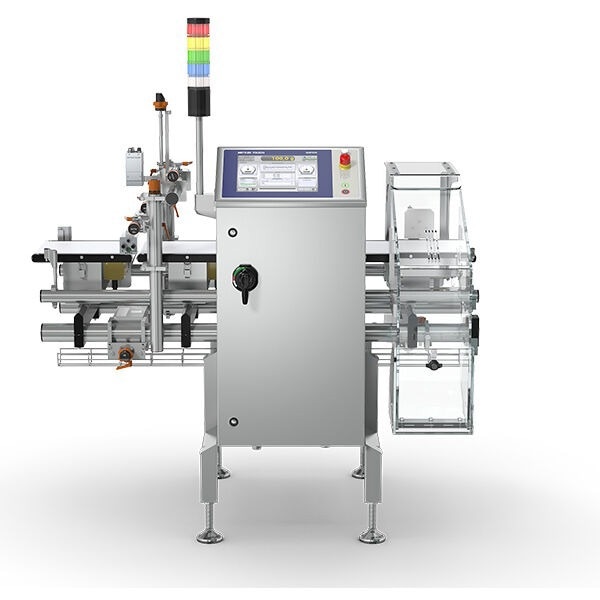

Seamless Integration

Perform configuration setups and modifications, such as product changeovers, just once for integrated product inspection technologies through the Checkweigher HMI, saving time and minimizing the potential for operator errors.

Image Credit: Mettler Toledo - International

ProdX - The Next Level in Product Safety

ProdX software enhances efficiency and cost-effectiveness by automating critical quality control processes. The securely stored data can facilitate business growth by supporting regulatory compliance and brand protection, demonstrating due diligence.

Image Credit: Mettler Toledo - International

Global Service Support

A worldwide network of service specialists delivers prompt remote and on-site assistance. The company’s extensive service offerings enable users to attain regulatory compliance, optimal performance, and maximum uptime throughout the entire life cycle of the product inspection equipment.

Image Credit: Mettler Toledo - International

Specifications

Specifications - CV Combination. Source: Mettler Toledo - International

| . |

. |

| Reading Devices |

Smart Camera |

| IP Rating |

IP54

IP65 |

| Compatible Software |

ProdX |

| Connectivity |

Ethernet TCP/IP

Fieldbus

OPC UA |

| Inspection Solution |

Checkweighing-Vision |

| Max Weighing Zones |

5 |

| Weighing Technology |

EMFR

Strain Gauge |

| HMI |

12" Touchscreen

15" Touchscreen |

| Packaging Type |

Bags

Bottle

Bundles

Cartons

Cases

Composite Cans

Flow Packs |

| Product Flow |

Conveyor |

| Max Camera Field of View |

110 x 110 mm |

| Label Quality Inspection |

Graphical ID

Label Placement

Label Skew

Label Wrinkles |

| Inspection Application |

Code Inspection

Label Inspection

Weight Control |

| Product Characteristic |

Deep Frozen

Dry

Medium-Large Packages

Open

Round Container

Small Individual Wrapped Products

Small-Medium Packages

Wet |

| Industry |

Chemical

Food & Beverage

Metal, Plastic and Electronics Components

Pharma & Biotech |

| Weighing Accuracy |

from ±0.01 g |

| Industry Segment |

Automotive

Bakery and Confectionery

Beer, Wine and Other Alcoholic Beverages

Cosmetics

Dairy

Fine and specialty chemicals

Food Additives

Meat & Poultry & Seafood

Nutraceuticals

Oils and Fats

Pet Food and Animal Feed

Ready Meals

Snack Foods

Sugar Starch and Yeast

Water and other Non-Alcoholic Beverages |

| Label Data Inspection |

1D/2D Barcode

Alpha Numeric |

| Max Product Weight |

10 kg |

| Max Line Speed |

180 m/min |

| Number of Reading Devices |

8 |

| Max Throughput |

500 ppm |

| Camera Inspection Area |

360°

Bottom

Side

Top |