LMI Technologies’ GoPxL Pro Tools is a series of inspection toolsets designed for specific applications. Each set combines a curated selection of GoPxL tools running on GoMax, purpose-built to tackle a defined inspection task.

Introducing GoPxL Anomaly Detector

Video Credit: LMI Technologies Inc.

Download the Brochure for More Information

Anomaly Detector

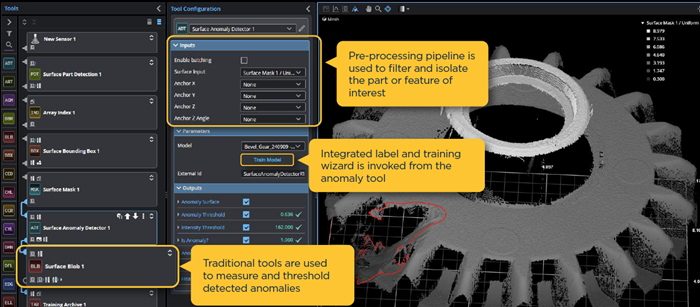

The GoPxL Anomaly Detector toolset combines traditional and AI-based tools within GoPxL to deliver powerful 3D defect detection for demanding applications in industries such as automotive, food, building materials, tire manufacturing, and more. The solution can be trained and deployed entirely on GoMax, eliminating the need for additional cloud or hardware resources for both initial and ongoing model training.

It integrates with all Gocator Line Profiler, Snapshot, and Line Confocal Sensors when powered by GoMax. The firmware is available for free download from the LMI website. A licensed LMI Dongle is required to operate Anomaly Detector with a live sensor, while license-free evaluation is available by running the firmware on GoMax in REPLAY mode.

Image Credit: LMI Technologies Inc.

Common Use Cases

Image Credit: LMI Technologies Inc.

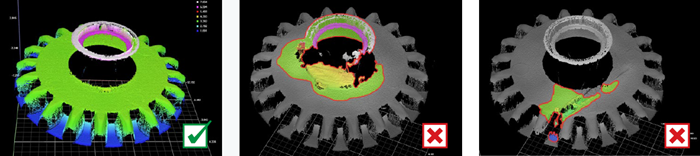

Part Inspection

Identify defects and irregularities on machined or cast parts with complex geometries. An AI model can be trained directly on the production line—without the need for a cloud connection, CAD file, or the complex thresholds typically required by traditional tools—to distinguish between good and bad parts.

Image Credit: LMI Technologies Inc.

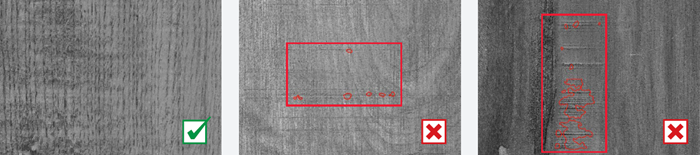

Surface Inspection

Detect defects and irregularities on flooring and building materials by combining traditional and AI-based tools in GoPxL. Surface edge and feature tools can be used to mask the board, while anomaly detection leverages intensity data to accurately locate defects.

Key Features

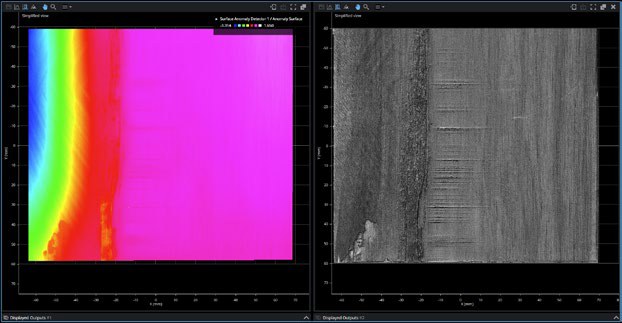

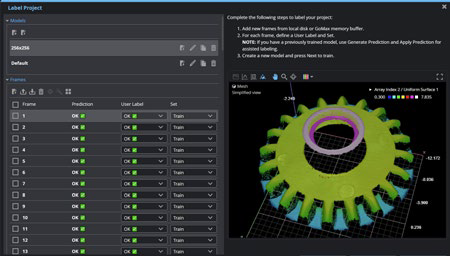

Train on 2D Intensity or 3D Height Map Data

Scan parts using both intensity and surface data, then select the optimal option during training. A 3D visualizer enables detailed viewing of complex parts, helping improve labeling accuracy.

Image Credit: LMI Technologies Inc.

Preview Functionality without a License

Evaluate anomaly detection on a GoMax in REPLAY mode, and train or perform inference without the need for a license.

Image Credit: LMI Technologies Inc.

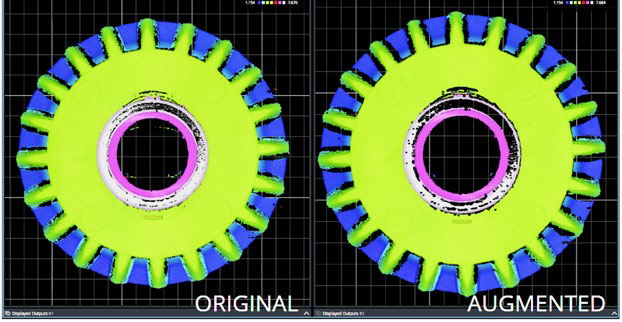

Generate Synthetic and Augmented Data

Reduce the number of images needed for training through integrated synthetic defect generation and augmented frames, enhancing overall model performance.

Image Credit: LMI Technologies Inc.

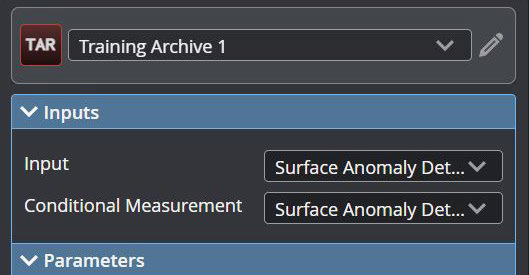

Store New Production Data Directly on GoMax

Use GoMax to store production data directly in a project archive. This enables rapid training of new models and improves overall application performance.

Image Credit: LMI Technologies Inc.

Integrated with GoPxL Benefits

Image Credit: LMI Technologies Inc.

Download the Brochure for More Information

Benefits

Detect Features of Varying Shape and Size

While traditional tools excel at blob detection and segmentation, they often require threshold tuning specific to each part. With GoPxL Anomaly Detector, detection thresholds do not need to be managed manually. Instead, training is based on providing a dataset of OK and NG parts, from which a detection model is created specifically for the parts in that dataset.

Image Credit: LMI Technologies Inc.

Integrated AI Modelling Workflow

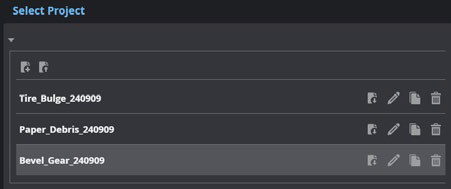

Model training and related datasets are managed entirely within GoPxL tools, reducing the need to move files and datasets between applications and saving time compared to using a separate training platform.

Image Credit: LMI Technologies Inc.

Train on the Production Line

Train data directly on GoMax to avoid the time, cost, and data security concerns associated with transferring data to the cloud or a local PC. Training and inference share the same license, enabling model updates in production without the need for an additional development license.

Image Credit: LMI Technologies Inc.

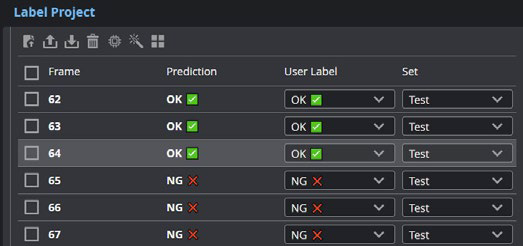

Use Prediction to Label New Production Data

After the initial training, use assisted labeling to make iterations quickly and conveniently.

Image Credit: LMI Technologies Inc.

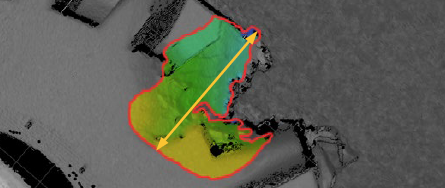

Measure Anomalies and Refine Acceptable Thresholds

Surface anomalies are passed to subsequent tools for measurement and gauging. Anomalies can be filtered by size or shape, based on the acceptance criteria defined by the end user.

Image Credit: LMI Technologies Inc.

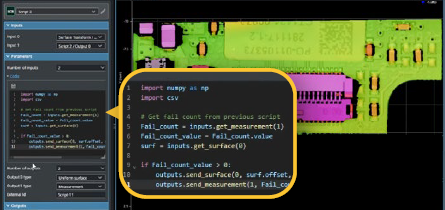

Add Custom Functionality with Script and Python GDK

The Python-based script tool allows users to add custom logic or load measurement thresholds from a local file. Advanced users can leverage the Python GDK to train models with open-source or proprietary tools, and then deploy them for production.

Image Credit: LMI Technologies Inc.