By Kalwinder KaurSep 21 2012

A research team from KIT headed by Professor Christian Koos has developed an innovative optical connection between semiconductor chips.

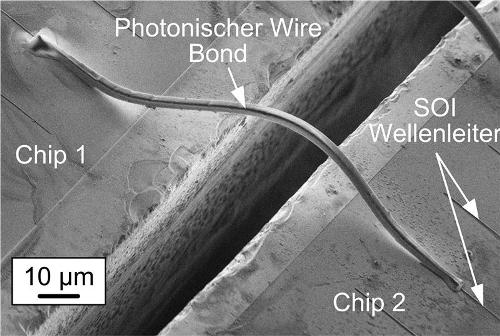

The wire bond is adapted to the position and orientation of the chips. (Figure: N. Lindenmann and G. Balthasar) ((Bildinschriften: Photonic wire bond, SOI waveguide))

The wire bond is adapted to the position and orientation of the chips. (Figure: N. Lindenmann and G. Balthasar) ((Bildinschriften: Photonic wire bond, SOI waveguide))

“Photonic wire bonding” enables the attainment of data transmission rates in the range of terabits per second and is apt for industrial-scale production. In the coming days, it is possible to use this technology in emitter-receiver systems with high performance for optical data transmission and enables reduction of the Internet’s energy consumption. The results were published in the journal” Optics Express”.

KIT Institute of Photonics and Quantum Electronics Professor, Christian Koos explained that the greatest challenge lies in precise chip alignment so that the waveguides meet. He is also the professor of Microstructure Technology (IMT) and a Center for Functional Nanostructures (CFN) member.

The research team first fitted the chips and next structured an optical waveguide based on polymers in a perfectly fitting way. In order that the interconnection suits the orientation and position of the chip, a technique was developed by scientists for three-dimensional structuring of an optical waveguide. Two-photon polymerization that ensures high resolution was used. The free-form waveguide structure was written by a femtosecond laser directly to a polymer present on the chip surface. A laser lithography system was used by KIT researchers that was manufactured by Nanoscribe, a KIT spinoff.

Photonic wire bond prototypes reached minimal losses and achieved an increased transmission bandwidth in the infrared telecommunication wavelength range around 1.55 µm. In initial experiments, the researchers showed data transmission rates more than 5 terabits per second. Since it is not required that the chips be oriented with high-precision, the process is suitable for automatic production of large series. This technology will be commercialized in collaboration with partner companies.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.