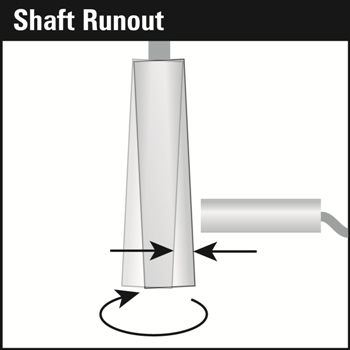

To help designers, engineers, and maintenance staff make better shaft runout measurements, Lion Precision has documented best practices in a new application note available on their website. Real-time shaft runout measurement is common in machine condition monitoring and other applications.

Like many measurement applications, there are unanticipated challenges for the uninitiated and a variety of solutions to those challenges. Even people with shaft runout measurement experience may discover that there is a better way.

Non-contact capacitive and eddy-current displacement sensors are the most practical methods for real-time measurements in an operating machine. Each sensing technology has advantages and disadvantages which are documented in detail in the new application note. The application note also includes strategies for mitigating sensor disadvantages and challenges so as to produce the most accurate measurement possible within the specific application.

Shaft runout as part of a condition monitoring system is common in power generation, ship drive systems, and other industrial machinery driven by a rotating motor. In such a system, bearing wear is inevitable. The condition of the bearings must be monitored to alert operators when bearings need to be replaced – before they fail with potentially catastrophic results. Without condition monitoring, bearings must be replaced on a defined periodic basis. This often results in either the costly and unnecessary replacement of perfectly good bearings or the catastrophic failure of a system in which the bearings fail prematurely.

The application note is available in the Technical Library section of the company website (www.lionprecsion.com) as a web page and PDF. The direct url for the application note is:

http://www.lionprecision.com/

“We want to help people make better measurements,” says Don Martin, president of Lion Precision. “Selling some of the world’s most precise sensors isn’t the only thing we’re about. We want to empower people to solve their measurement problems.” To that end, the company is developing an entire library of Application Notes and TechNotes to provide design and maintenance professionals all the information they need to get the best measurement results possible with non-contact displacement sensors. These documents are available in the Technical Library on the company website (www.lionprecsion.com).

Lion Precision started in 1958 as the first provider of capacitive displacement sensors to industry. The company has expanded its product offering to include eddy-current displacement sensors and some application specific sensors for the machine tool, packaging and PCB industries. The company is focused on assisting users in sensor implementation by providing technical knowledge resources, expert guidance and optimized systems including custom designs.