Aug 12 2010

The microelectromechanical system (MEMS) technology enables small machine to fine-tune itself so as to make highly precise sensors which could serve medical diagnostics, environmental testing and crime forensics.

The MEMS technology will help researchers to design a "nose-on-a-chip" for tracing suspects of crime, sensors to determine harmful substances and developing tools for biotechnology and nanotechnology works. The research work executed in Purdue's Discovery Park at the Birck Nanotechnology Center has been described in 2 papers. The gyroscopes and MEMS accelerometers are commercially used now-a-days in walking robots, automotive airbags, the Nintendo Wii video game and the iPhone.

According to Jason Vaughn Clark, Assistant professor of electrical, computer and mechanical engineering, there are no standard devices and practical methods to calibrate micro or nano structures that are too diminutive. He also commented that the former conventional techniques used to measure movement and force of miniature components on the micro, nanometer scale provided vague, erroneous results and the microstructures never shared a common material and geometric characteristics due to fabrication errors in the process.

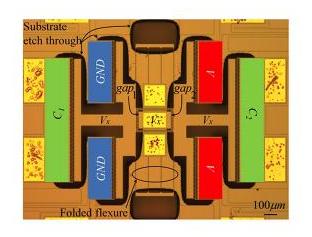

The image depicts a device that enables tiny micro electromechanical systems to "self-calibrate," an advance that could make possible super-accurate sensors, a "nose-on-a-chip" for law enforcement and a new class of laboratory tools for specialists working in nanotechnology and biotechnology

The image depicts a device that enables tiny micro electromechanical systems to "self-calibrate," an advance that could make possible super-accurate sensors, a "nose-on-a-chip" for law enforcement and a new class of laboratory tools for specialists working in nanotechnology and biotechnology

Clark explained that the deviation in width by 10% alters the tautness of the microstructure on the whole and the functioning efficiency of MEMS is incapable of predicting due to method disparity.

The electro micro metrology (EMM) upgraded by Clark discovers the accurate force and movement that acts upon or experienced by the MEMS thereby registering the discrepancies in the process. Clark added that the MEMS is capable of appraising itself for the first time and could resolve their mechanical properties thereby acting as specific sensors.

According to him, the conventional tools fail to calibrate van der Waals forces, nanoassembly, Casimir forces, hydrogen bond forces in DNA and opaque data storage in terms of piconewtons. With the conventional technology alone it is arduous to design prognostic representations. Clark said that EMM technology is highly exact and outfaces conventional macroscale measuring technology. EMM uses electrical capacitance to depict the mechanical characteristics of microstructure such as rigidity, force and contour.

Microtools can auto-calibrate in order to resist extreme environments with a prolonged stay Nanotechnologists use atomic force microscopy techniques to enhance the instruments’ accuracy by determining minute forces and displacements. But the accuracy of calibration cannot be predicted, Clark added.

The research group lead by Clark plans to educate the users in calibrating instruments with the help of MEMS in addition to designing a minute "AFM-on-a-chip," reducing the cost of experimental equipments. Clark wishes that his approach on the "AFM-on-a-chip,” will attract many people to the nanotechnology world.

The first generation MEMS which could calibrate on its own has been designed and experimented by the Clark’s research team and identified the existence of van der Waals forces and Casimir effect.