In this interview, AZoSensors talks to Mike Grodzki, a Product Manager at Teledyne DALSA, about the use of SWIR cameras in agricultural sorting and inspection and the benefits this brings to the field.

Can you tell our audience the theory behind SWIR cameras detecting moisture?

Water is highly light absorbent in the shortwave infrared (SWIR) region, so it appears almost black in images of objects taken by SWIR cameras. As a result, applying an appropriate filter or light source can help make moisture content highly evident in bruised fruit, well-irrigated crops, or bulk grains, for example. Thanks to this property, scientists can precisely follow water absorption from the roots into the leaves.

Conversely, evaporation and desiccation can also be seen. SWIR’s shorter wavelengths enable images to be acquired with higher resolution and stronger contrast, both of which are important criteria for inspection and sorting.

How can SWIR cameras be used to view the levels of moisture in agriculture?

Water absorbs SWIR around 1400 nm. To determine water content, we need to be able to see the ‘brightness’ of the sample outside the water absorption (say at 1200 nm) and inside (say at 1450 nm).

Linea SWIR supports up to four cycling sets, combining with pulsing LEDs from major machine vision lighting producers to provide low-cost, high specificity spectra analysis in the SWIR band. As the object passes through, we can switch the light source between 1200 nm and 1450 nm for alternating triggers.

We use the camera to track the trigger, associating the output with the correct wavelength and adjusting gain, correction and exposure time for each wavelength. This process gives us a good spectral analysis of our sample in real-time, fast and fully synchronous with the operation.

Then, we compare the two ‘colors’ for relative intensity, and we can derive the water content and decide whether it is good or bad.

How does this improve the sorting process from traditional agricultural sorting methods?

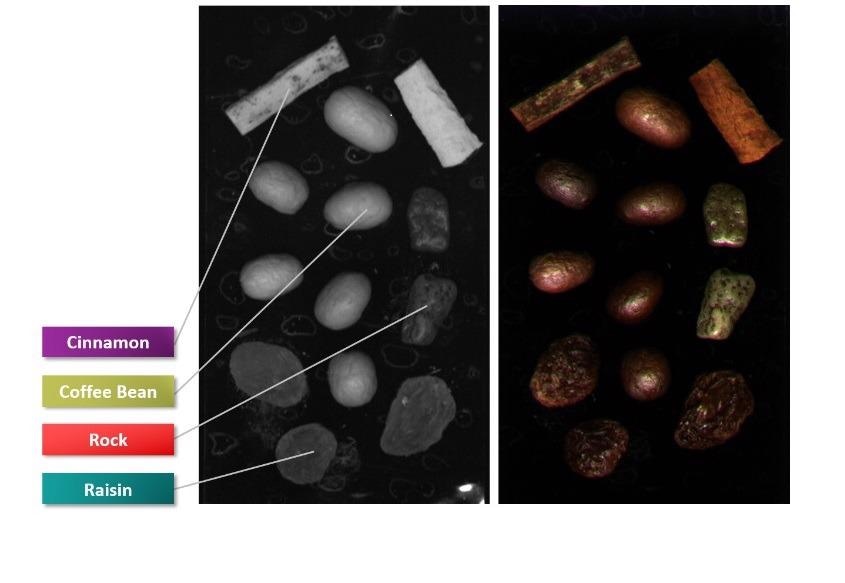

Using apples as an example, traditional sorting involves using visible identifiers to determine fruit quality, such as shape, size, color, texture and defects. SWIR improves this process by allowing you to see water density and distribution more clearly inside the apple.

This indicates key physical attributes that will help predict the measurable ‘quality’ of the apple, for example, texture, water binding capacity and specific gravity. Identifying abnormalities such as bruising (which causes physical changes in the texture and chemical composition of the fruit) helps determine immediate and long-term effects on color, smell, taste, and longevity of the product.

What benefits does the Linea SWIR camera bring to agricultural sorting?

Linea SWIR helps manufacturers increase yield, reduce waste, and improve quality by identifying bruised products which can be caught and removed from the food sorting process. There is less likelihood of waste because foods like apples can instead be sorted by their suitability for other products, like jams, preserves, and frozen mixes.

In addition to defects, it can detect foreign contaminants that do not belong in the product stream.

How do these benefits differ from what is currently available on the market?

Linea SWIR provides improved signal to noise ratio in a compact GigE package that supports up to four different light sources, lighting angles, exposure times, or gain settings in a single pass.

Are there any alternative applications the Linea SWIR camera can be used for?

In addition to food production and sorting, Linea SWIR is also ideal for optical sorting, solar panel inspection, recycling, silicon wafer inspection and general-purpose machine vision.

What is the next step for Teledyne DALSA?

Teledyne DALSA will continue to develop powerful, leading-edge SWIR technology with cutting-edge features and value.

About Mike Grodzki

Mike began his career at Teledyne DALSA as a Research Analyst, and since 2018, has served as Product Manager for the company’s Linea SWIR series, and the soon-to-be-released Linea2 line scan cameras. Mike is a passionate product professional and thrives on building relationships with customers to understand their pain points and drive a product strategy that resonates with the market.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.