The water or wastewater industry has several needs for quantifying the water level in applications like pipes, weirs, flumes, cooling towers, basins, wells, and tanks. Ultrasonic sensors are economical and reliable for such applications.

During operation, the ultrasonic sensor is fitted above the water. The sensor finds the distance to the water by sending a sound pulse that is reflected from the water surface and measuring the time taken for the echo to return*.

At times, structural components, like a small pipe, are fitted in the acoustic path between the water and the ultrasonic sensor.

*A more comprehensive overview of the fundamentals of ultrasonic sensors is included in the two-part article titled “Choosing an Ultrasonic Sensor for Proximity or Distance Measurement,” penned by the author of this article and published in the February and March 1999 editions of Sensors Magazine. Reprints of this article can be obtained at https://www.massa.com/publications/.

Such components might reflect a part of the sound and generate a false echo that meddles with the sensor’s potential to correctly detect the echo from the water surface.

Sophisticated ultrasonic sensors can be tuned to overlook such false echoes, which thus allows them to offer accurate water level measurements. The next section explains how this can be achieved.

How an Advanced Sensor can Ignore False Echoes

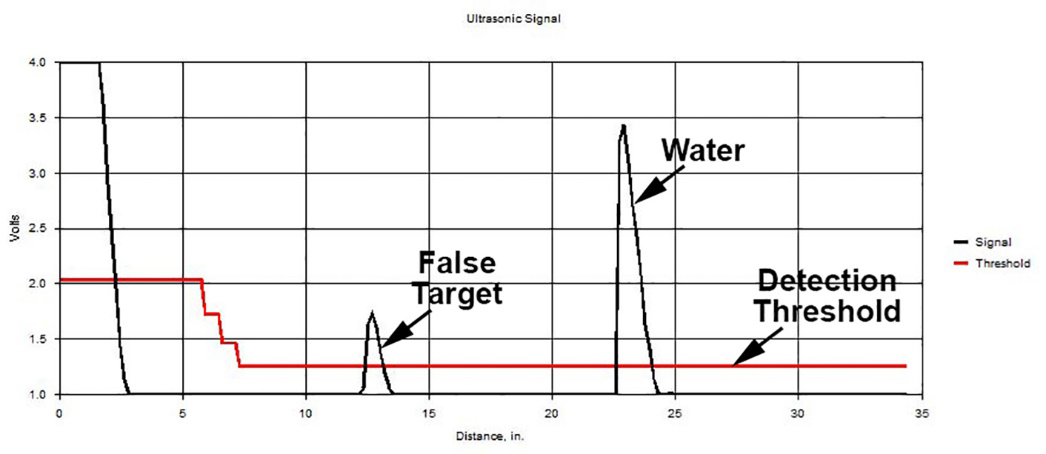

Figure 1 illustrates an example of an ultrasonic waveform. It displays graphs of both the received ultrasonic signal’s magnitude and the detection threshold’s magnitude as a function of distance to the sensor.

Figure 1. Ultrasonic waveform from a MassaSonic™ PulStar™ Plus Sensor showing a false target being detected instead of the echo from the surface of the water. Image Credit: Massa Products Corp.

The black curve signifies the magnitude of the ultrasonic signal that has been received, and the red curve shows the magnitude of the detection threshold for the standard factory setting.

There are two target echoes in the plot of the ultrasonic signal. The first one is that of a false echo, for example, an echo generated by a pipe situated in the acoustic path between the sensor and the water, and the second one indicates the echo from the water surface.

As illustrated, the false target tends to be more than the standard factory-set detection threshold. Hence, the sensor would perceive it as the surface of the water and offer an inaccurate level reading.

The MassaSonic™ PulStar™ Plus Sensor enables users to exhibit an ultrasonic waveform on a computer screen and alter the detection threshold levels at various distances from the sensor. Thus, the threshold can be raised around the false target such that it is not detected.

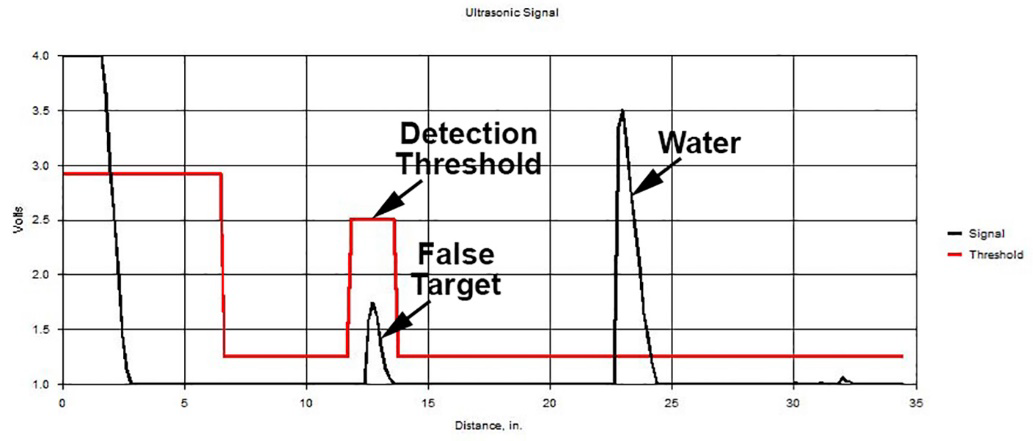

Figure 2 depicts the ultrasonic waveform obtained after adjusting the detection threshold levels. It can be observed that the threshold in the region across the false target has considerably increased more than the echo’s amplitude.

Figure 2. MassaSonic™ PulStar™ Plus ultrasonic waveform with the same targets as in Figure 1, but with the detection threshold modified to ignore the false target. Image Credit: Massa Products Corp.

In this case, the sensor overlooks the echo from the false target and detects only the water echo, thus offering accurate water level information. The sensor often detects the echo from the water precisely, even if the surface of the water moves to the same location as that of the false target.

The reason is the magnitude of the water echo is much higher compared to the level of the detection threshold fixed over the false target. Figure 3 shows a MassaSonic™ PulStar™ Plus Sensor.

Figure 3. MassaSonic™ PulStar™ Plus Sensor. Image Credit: Massa Products Corp.

This information has been sourced, reviewed and adapted from materials provided by Massa Products Corp.

For more information on this source, please visit Massa Products Corp.