Accurate torque measurement helps engineers to monitor and improve twisting mechanisms, both on the test bench and in the field.

This guide will break down the fundamentals of torque sensors, their types, working principles, and applications, while answering key questions like:

Let’s take a look.

What is Torque?

A torque sensor measures the rotational force applied to an object, such as a shaft, engine, or pedal. This force, torque, is essential in understanding mechanical performance. It is generally measured in units like Newton-meters (Nm) or pound-feet (lb-ft).

Torque sensors convert torque into an electrical signal that can be monitored, recorded, or analyzed. Engineers use torque sensors to evaluate systems under load, test motors and engines, or enhance the real-time performance of machines. They are often essential for troubleshooting and improving system design.

The two main categories of torque are:

-

Static Torque: Twisting force applied to an object that does not cause rotation or results in a constant rotational speed, otherwise known as the torque measured at rest. (e.g., a tightened bolt).

-

Dynamic Torque: Twisting force applied during rotation (e.g., a spinning motor shaft).

Understanding this distinction is essential for choosing the right sensor. For instance, dynamic torque applications often require sensors with high-speed accuracy and minimal mechanical interference, such as contactless transducers.

How Does a Torque Sensor Work?

Before we discuss the working principles of torque sensors, it’s worth sorting the nomenclature. The terms "sensor" and "transducer" often seem interchangeable in the context of torque measurement, but they are distinct.

A torque sensor is a broad classification of any device that measures rotational force (static or dynamic).

A torque transducer, meanwhile, is a specific type of sensing element that converts the mechanical torque input into an electrical output (analog, digital, or voltage).

Got it? Here’s how torque sensors work:

1. Deformation and Strain Measurement

When torque is applied, the shaft or mechanical element undergoes a slight deformation.

Torque sensors measure this deformation using technologies like:

-

Strain Gauges: Strain gauges, arranged in a Wheatstone Bridge Circuit, measure the strain on the shaft caused by torque. HBM torque transducers, for instance, achieve extremely high precision by compensating for parasitic effects like bending or axial forces.

-

Magnetostrictive Sensors: Measure the magnetic properties of a material, which change under stress.

-

Optical Torque Sensors: Use optical systems with light and reflective elements to detect angular displacement.

In rotating systems, contactless energy transmission is often used to measure torque dynamically without wear and tear.

This technology ensures minimal signal noise even at high rotational speeds.

2. Signal Conversion

Deformation changes the resistance (or other properties) of the sensor. For strain-gauge-based sensors:

For high-speed applications, contactless signal transmission using frequency-modulated signals allows precise measurements without physical connections.

3. Output and Monitoring

The torque data is transmitted to data acquisition systems (DAQ) or monitoring tools for real-time analysis. In high-performance systems, sensors with 10 kHz frequency output ensure excellent dynamic response.

4. Real Life Examples of Torque Sensors

In modern vehicles, especially those with Electric Power Steering (EPS), steering torque sensors are used for precision and safety.

They work in a few different ways:

-

Placement: Sensors are integrated into the steering column.

-

Force Detection: Torque applied to the steering wheel creates torsional strain, which is detected via strain gauges or other technologies.

-

Signal Processing: The strain is converted into an electrical signal that is processed by the control system.

These sensors work to improve:

- Power Steering Assistance: Adjusts motor output dynamically.

-

Advanced Driver Assistance Systems (ADAS): Provide real-time data for lane-keeping, adaptive cruise control, and collision avoidance.

-

Driver Feedback: Ensures a smoother, more controlled driving experience.

eBikes also make use of torque sensors for improved energy efficiency and performance. But how does that work in these electrical two-wheelers?

-

Force Measurement: Sensors measure the torque applied to the pedal or crankshaft.

-

Adaptive Motor Assistance: Based on the measured torque, the motor adjusts its output proportionally. The harder you pedal, the more assistance you receive.

Advantages:

-

Natural Cycling Feel: Provides smooth, intuitive motor assistance.

-

Battery Efficiency: Conserves energy by optimizing motor output.

-

Seamless Transitions: Ensures smooth changes between manual and motorized pedaling.

The alternative to integrating torque sensing in e-bikes is cadence sensing, which detects pedalling speed rather than torsional force.

This isn’t generally as responsive, and so provides less control and poorer efficiency. As a result, torque sensors are typically preferred for premium e-bikes.

Manufacturers of Torque Sensors

FUTEK Advanced Sensor Technology Inc. is a sensor manufacturing company that produces both rotary and reaction torque sensors of different types.

Their range includes torque wrench reaction torque sensor, square drive to square drive reaction torque sensor, shaft to shaft reaction torque sensor, shaft to shaft rotary torque sensor, and many more.

Similarly, Althen Sensors and Controls produce rotary shaft torque sensors ranging between 0.01 nNm and 10 kNm for dynamic measuring and strain gauge-type static torque sensors for aerospace, automotive, offshore, and marine applications.

In addition, the company uses strain gauge and Surface Acoustic Wave (SAW) technologies for their different type of sensors.

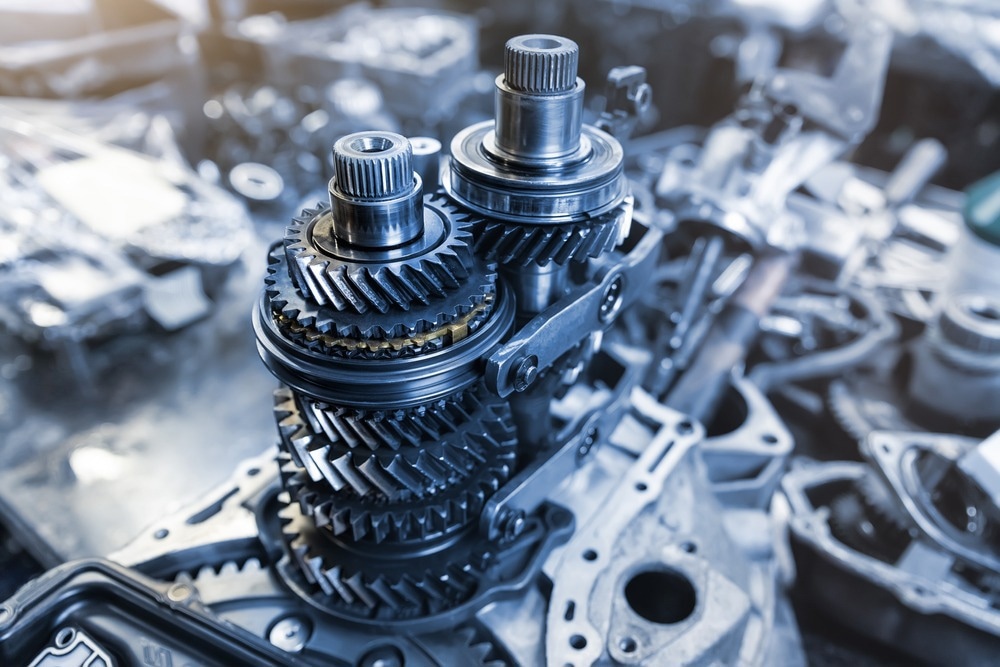

Image Credit: Gorloff-KV/Shutterstock.com

Industrial Applications

Torque sensors are crucial for process optimization and quality assurance. Key examples include:

Torque sensors are used in the aerospace industry to track an aircraft engine's torque, aiding in performance monitoring and operational safety.

They can be used in the manufacturing sector to track the torque applied to different components during assembly. The data obtained from the sensors is then used to verify that components are assembled correctly and to identify any errors that may have occurred during the assembly process.

Torque sensors are employed in many other areas, including the medical, robotics, and renewable energy sectors.

They can also be used in scientific investigations, such as analyzing human motion and evaluating muscular power.

Challenges in Torque Measurement

Torque measurement systems face numerous challenges that can affect their performance, precision, and reliability. Addressing these issues requires careful consideration of system design, alignment, and environmental influences.

Like all measurement instruments, load cells and torque sensors are subject to aging. Mechanical stress and fatigue experienced through normal use will cause sensors to "drift" over time. Although this instability cannot be prevented, it can be identified and corrected by a well-designed calibration program.

Jonathan Armstrong, Sensing Systems Corporation

Read the full interview with Jonathan Armstrong!

Here’s a closer look at the primary challenges and their solutions:

|

Aspect

|

What It Is/Challenge

|

Impact/Result

|

Solution

|

|

Parasitic Loads

|

Parasitic forces (bending moments, axial, radial forces) act alongside torque during operation.

|

Distorts measurement accuracy, especially in high-sensitivity systems.

|

Use flexible couplings or compensating components to isolate the transducer.

|

|

Dynamic Torque

|

Measuring sudden torque peaks caused by vibrations, accelerations, or abrupt changes.

|

Torque oscillations in engines or motors due to pressure fluctuations and transients.

|

Use transducers with broader ranges or torsionally elastic couplings to dampen forces.

|

|

Environmental Factors

|

Temperature changes, humidity, contamination, and electromagnetic interference (EMC).

|

Mechanical strain, false readings, and signal disruption.

|

Deploy robust, sealed (IP-rated) transducers with shielding and thermal compensation.

|

|

Alignment Errors

|

Misalignments in the shaft train induce deformations and stresses on the transducer.

|

Measurement inaccuracies and potential mechanical damage.

|

Use precision alignment tools like laser triangulation and flexible couplings.

|

|

Vibration and Resonance

|

Torsional, axial, or bending vibrations introduce dynamic forces and amplify effects at resonance.

|

Unreliable or fluctuating torque values.

|

Apply damping couplings and optimize shaft designs to avoid resonance at critical frequencies.

|

|

Signal Transmission

|

Mechanical slip rings wear over time, generating noise and requiring maintenance. Contactless systems need precise alignment and are susceptible to interference.

|

Reduced longevity or signal quality.

|

Favor contactless technologies (e.g., inductive or optical systems), ensure alignment precision, and use proper shielding.

|

|

Accuracy Limitations

|

Non-linearity, hysteresis, and repeatability errors from mechanical and electronic imperfections. Dynamic changes may exceed the transducer bandwidth.

|

Reduced precision in highly dynamic measurements.

|

Select high-precision strain gauge-based transducers with advanced calibration and signal conditioning.

|

|

Calibration Challenges

|

Static calibration may not represent real-world dynamic torque conditions.

|

Calibration inaccuracies in dynamic applications.

|

Use dynamic calibration systems that simulate actual operational loads.

|

Interested in learning more about torque sensors?

Torque sensors are indispensable in precision engineering, enabling optimized performance, energy efficiency, and safety across industries. Innovations like wireless telemetry and greater IoT integration promise even greater capabilities in the near future, and it’s clear that torque sensors will play a pivotal role in enabling autonomous vehicles, robotics, and next-generation manufacturing systems, where precision, reliability, and real-time data integration are critical for AI-driven automation and autonomous operations.

If you’re interested in further reading about the changing world of sensors, browse thousands of articles exclusively on AZoSensors.

Read more about torque sensors here!

At AZoSensors, we don’t supply torque sensing solutions, but we do promote a competitive range of torque sensors from leading manufacturers across the globe. If you have a specific manufacturing, research, or development problem, we can help you connect with suppliers who may have the solution.

References and Further Reading

Kang Min, Fenglei Ni, & Hong Liu (2023) An efficient and accurate force/torque sensing method based on an excitation trajectory. Industrial Robot. https://www.emerald.com/insight/content/doi/10.1108/IR-08-2022-0206/full/html

P. H. Kim, B. D. Hauer, C. Doolin, F. Souris & J. P. Davis (2016) Approaching the standard quantum limit of mechanical torque sensing. Nature Communications. https://www.nature.com/articles/ncomms13165

Torque Sensors: Althen Sensors & Controls. (2023) Retrieved February 20, 2023, [Online] Available at: https://www.althensensors.com/sensors/torque-sensors/

Vatavuk, I., Stuhne, D., Vasiljevic, G., & Kovacic, Z. (2023). Direct Drive Brush-Shaped Tool with Torque Sensing Capability for Compliant Robotic Vine Suckering. Sensors. https://www.mdpi.com/1424-8220/23/3/1195

What is a torque sensor? (2023) FUTEK Advanced Sensor Technology. Inc. Retrieved February 20, 2023, [Online] Available at: https://www.futek.com/what-is-a-torque-sensor

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.