Mid-infrared (mid-IR) gas sensing refers to the detection and measurement of gases using light in the mid-infrared wavelength range, typically 2.5-25 μm. This technique relies on the principle that molecules absorb specific wavelengths of infrared light matching their inherent resonant frequencies, which leads to vibrations and rotations in the molecular bonds.

In addition, many organic molecules and key inorganic gases exhibit their primary optical absorption bands in the mid-IR region, corresponding to their fundamental roto vibrational modes.

By directing mid-IR light through a sample gas and measuring the transmitted light intensity at different wavelengths, an absorption spectrum' fingerprint' is acquired, which helps determine the type and concentration of unknown gases. The amount of absorption follows the Beer-Lambert law, allowing quantification of a gas's concentration.

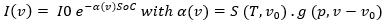

Where I(ν) represents the frequency-dependent transmitted intensity following the traversal of a measurement cell with an optical path length So. Here, α(ν) signifies the frequency-dependent gas-specific absorption coefficient, and c denotes the gas concentration. This coefficient is determined by the product of the pressure-dependent line shape function, g (p, ν −ν0), and the temperature-dependent line strength, S (T, ν0), at the characteristic absorption frequency ν0.

Small gas molecules like CO2, CO, N2O, NH3, C2H2, and CH4 yield much stronger mid-IR absorption signals than overtone bands at shorter near-IR wavelengths, providing sensitive detection in the parts-per-million to parts-per-billion range.

Instrumentation And Components of a Standard Mid-IR Gas Sensor

While significant innovation is underway, mid-IR sensors fundamentally integrate three main elements:

Light Source

Traditionally containing glowing filaments, thermal emitters use micro-hotplates designed with MEMS techniques. Semiconductor sources like quantum cascade lasers (QCLs) and LEDs are increasingly becoming popular for detecting very small concentrations of pollutants in the air.

Gas Cell

A chamber with an inlet and outlet enables mid-IR light interaction with the sample gas, offering variable path lengths (up to a few millimeters) for balanced signal strength and compact device size. Reflective surfaces, such as gold, are commonly employed to reflect light internally, increasing the path length.

Detector

Thermal detectors, such as thermopiles and pyroelectrics, are commonly used to measure transmitted light intensity thanks to their lower cost, room temperature operation, and broad wavelength response. Photodetectors are often employed for higher sensitivity but selectively chosen for specific spectral bands.

These components are packaged together using free-space optics or integrated onto photonic chips, accompanied by microfluidics for gas transport.

Image Credit: Aleksandar Malivuk/Shutterstock.com

Applications of Mid-IR Gas Sensing

The molecular specificity of the mid-infrared sensors makes them highly useful across diverse gas sensing challenges in the industrial, environmental and medical spaces.

Environmental Monitoring Systems

Mid-IR gas sensing is extensively used to detect prominent greenhouse gases, notably carbon dioxide and methane, contributing to climate change. Their high sensitivity range allows accurate quantitative measurement for tracking emissions and atmospheric concentrations.

Such sensor systems are also deployed in smart buildings' pollution monitoring networks and HVAC systems for indoor air quality control and energy efficiency optimization.

Hazardous Gas Monitoring

Petrochemical plants, refineries, fuel distribution infrastructure and other facilities dealing with oil, gas or specialty chemicals require rigorous monitoring to detect leaks of combustible gases like methane and propane alongside toxic gases like ammonia. Mid-IR sensors offer selective, fail-safe operation for autonomous safety systems.

Sulfur hexafluoride (SF6) is often used as a marker gas with mid-IR sensors to detect and analyze the distribution of hazardous gases. This approach releases low concentrations of SF6 into the area of interest, and the distribution pattern is measured over time using multiple sensors.

Process Gas Composition Measurement

Mid-IR analyzers measure the multi-component makeup of gases involved in chemical reactions and other industrial processes. For example, they determine concentrations of C1-C4 hydrocarbons and other constituents in natural gas to calculate heating value. They also detect trace impurities like acetylene during ethylene production.

Custom narrow linewidth mid-IR diode lasers combined with multi-pass gas cells provide the required selectivity and sensitivity below ten ppb levels in complex gas matrices.

Automotive Emissions Testing

Automobiles integrate mid-IR sensors to detect and prevent leakage of air conditioning refrigerants inside the cramped engine compartment where flammable gases accumulate. Cabin air quality is also monitored using mid-IR carbon dioxide detection from occupants' exhalation to actively control ventilation as concentrations rise.

Stringent regulations on permissible levels of nitrogen oxides, ammonia and other byproducts in diesel and gasoline vehicle exhaust require extremely sensitive gas analysis capabilities down to single-digit parts per million. Specialized mid-IR sensors employing tunable diode laser absorption spectroscopy and Fourier-transform infrared spectroscopy supply the necessary detection limits and immunity to the harsh, dirty exhaust environment.

Moreover, they provide the time resolution needed for transient engine testing.

Human Breath Analysis

When analyzed in the mid-IR range, the diverse assortment of volatile organic compounds in human breath can indicate certain respiratory diseases, cancers and infections.

Mid-IR breath sensors enable rapid, noninvasive diagnosis and therapy monitoring by detecting exhaust gases like carbon dioxide and nitric oxide alongside over 200 volatile organic compounds (VOC) biomarkers correlated with specific illnesses.

Compact and precise mid-IR breath sensing technology is helping progress from basic research toward clinical breath testing devices suitable for point-of-care medical applications as sensor hardware becomes smaller and more selective.

In addition, capnography using mid-IR absorption provides critical monitoring of carbon dioxide in patient exhalation during anesthesia delivery and other respiratory treatments via precise, continuous measurement.

Conclusion

The above applications highlight the versatility of mid-IR gas sensing. As research continues to develop more compact, low-cost integrated optical components and photonic chips, mid-IR sensors will become widely accessible for personalized health monitoring, smart city sensing, and more in the coming decades.

References and Further Reading

Lambrecht, A., & Schmitt, K. (2020). Mid-infrared gas-sensing systems and applications. In Mid-infrared Optoelectronics, pp. 661-715. Woodhead Publishing. doi.org/10.1016/B978-0-08-102709-7.00016-4

Tournié, E., & Cerutti, L. (Eds.). (2019). Mid-infrared optoelectronics: materials, devices, and applications. Woodhead publishing. doi.org/10.1016/C2017-0-03995-2

Popa, D., & Udrea, F. (2019). Towards integrated mid-infrared gas sensors. Sensors, 19(9), p. 2076. doi.org/10.3390/s19092076

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.