In this interview, AZoSensors talks to Inder Kohli, Senior Product Manager at Teledyne DALSA, about 3D laser triangulation, how it can help the vision technology industry and everything else about 3D imaging,

What is 3D Laser Triangulation?

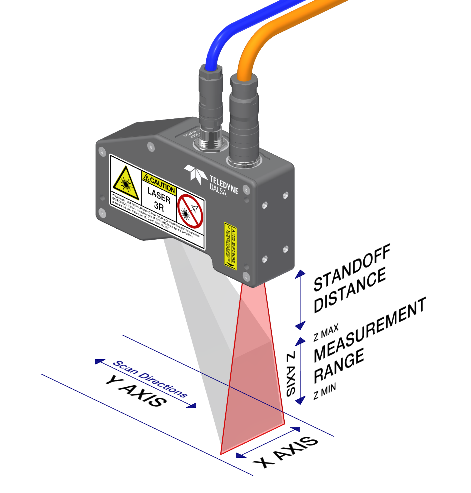

As the name suggests, this technique uses a trigonometric calculation to compute the height of an object from an image of a laser line (or a laser spot) projected onto an object.

Image credit: Teledyne DALSA

Can you explain how 3D vision technology has changed over the past two decades?

Like various other technologies, 3D laser profilers have also benefitted from the increasing density at higher speeds, reduced footprint, and increased level of microchip integration. Higher speed, bigger FPGAs with dedicated microprocessors and low power, small footprint lasers have made 3D laser profilers more accessible for several inline inspection applications.

Why did 1D (line scan) and 2D (area-imaging) dominate the industry 15 years ago?

Both 1D and 2D imaging sensors continue to thrive because these are one of the core building blocks of 3D laser sensors. For example, high frame rate image sensors with integrated image enhancement features allow 3D laser profilers to deliver higher resolution and higher reliability.

What gives 3D tech the edge over these platforms?

Parallel advancements in image sensor quality and speed, embedded vision, FPGAs, lasers, optics, and smart systems have made 3D imaging a much more viable option today. 3D imaging technologies are now low-cost, reliable, repeatable, easy to implement, and proven in a wide variety of demanding applications. While 1D and 2D are still in wide use, 3D can now add invaluable information to the decision matrix in nearly every instance.

For better results, applications often combine 1D, 2D and 3D cameras and sensors to get more information about the object on which to base the decisions. Better decisions can drive efficiency, reduce wastage, and increase profitability.

What 3D Laser Triangulation platforms does Teledyne offer? How do these compare with similar devices available to consumers?

Image credit: Teledyne DALSA

The Z-Trak2™ family of 3D Laser Profilers features Teledyne’s 3D image sensor technology. The Z-Trak2 S2K0 series, with its 45,000 Hz profile and 5GigE Vision interface, targets high-speed, in-line 3D measurement applications, while the Z-Trak2 V2K0 series, with a 10,000 Hz profile rate and 1GigE interface, is designed for cost-sensitive inline measurement applications.

In addition, the Z-Trak2 family features hardware-based, real-time profile acquisition and processing functions that simplify system design while minimizing processing overheads. With its single scan HDR, Z-Trak2 scans surfaces of varying degrees of reflectivity, it avoids the complexity of image alignment and image stitching required when using multiple scans with different exposure times to capture the surface details.

Single cable multi-sensor synchronization and its ability to create a common measurement space by combining multiple Z-Traks of different types ensure robust, reliable and repeatable results.

Can you explain how 3D Laser Triangulation builds an image?

A typical 3D laser profiler uses a trigonometric relationship between a laser line and a 2D image sensor to perform the measurements. A 3D laser profiler contains a laser at a known distance from the image sensor; the image sensor is tilted at a known angle with respect to the laser.

The distance, angle, and position of the laser line as imaged on the sensor are used to calculate the height (Z) and width of the object along the laser line (X). A known displacement between two consecutive profiles provides the length along the motion (Y).

How has this technology been kept low-cost?

Integrated laser triangulation profilers are easier to use and set up and require no special operator training to get the results. For example, all Z-Trak2 models are factory calibrated to output height and width in world measurement units.

In addition, all Z-Trak2 models use standard off-the-shelf cables and network components to build cost-effective 3D measurement systems. To further keep the total ownership cost low, Teledyne DALSA also offers a free Sherlock 8 software license (a field-proven point-and-click machine vision software package for factory floor applications) when using Z-Trak1 or Z-Trak2.

Can you explain how advancements in high-speed CMOS sensors combined with FPGA and powerful embedded systems have boosted this technology?

High performance CMOS image sensors deliver a high frame rate and on-chip features like HDR, binning, and multiple AOIs. A high frame rate/profile rate allows 3D profilers to scan fast-moving objects with higher resolution without slowing down the production line. When combined with FPGA, the profilers can off-load processors from various pre-processing steps while delivering results deterministically.

What range of resolutions can 3D Laser Triangulation operate at without sacrificing accuracy?

A wide range of optical arrangements is possible with this technology without having to change the processing architecture. Simply changing the mechanical and optical design to obtain diverse resolutions can scale from several meters down to 5 microns.

Why are users now increasingly turning to this technology?

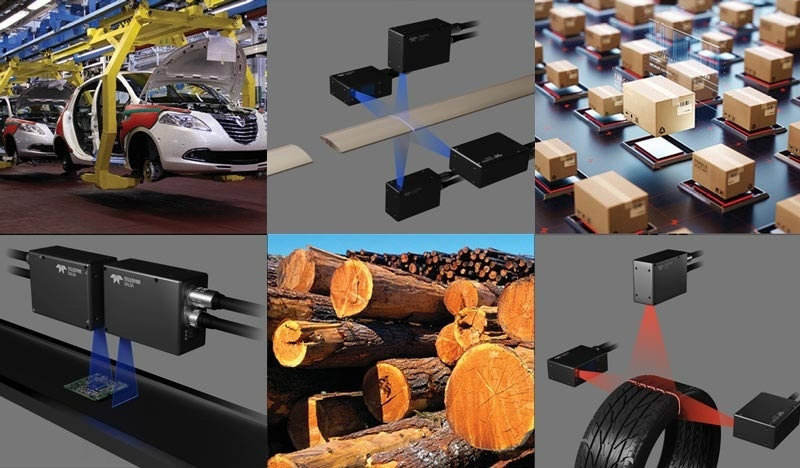

Decreasing costs, increasing speed, ease of deployment and maintenance are enabling a wider acceptance of 3D profilers. Almost all machine vision applications can use inline height, width, and length measurements to improve product quality and reduce waste.

Image credit: Teledyne DALSA

What makes this technology easy to integrate, and why is this advantageous?

Integrated laser triangulation profilers like Z-Trak2 include a laser, a 2D image sensor, lens, and filters, and these are all factory calibrated. They target ease-of-use and low maintenance, as they require no special operator training or any in-field re-calibration.

In addition, some profile sensors, like Z-Trak2, use standard off-the-shelf cables and network components to build cost-effective 3D measurement systems. Interoperable with 3rd party or proprietary software packages make the integration flexible and preserves the investment in the software tools. To help reduce the cost of ownership further, Teledyne DALSA offers a free Sherlock 8 software license.

How can AI be used to boost this technology?

Developments in modern electronics and artificial intelligence (AI) have enabled systems to become even more powerful and at a reasonable cost. For example, our Z-Trak family of profilers output profiles and also the intensity data at the same time. By combining this data, AI models can classify different defects.

What are some of the drawbacks to 3D Laser Triangulation? How is Teledyne working to combat these?

The triangulation setup used in the profilers creates occlusion because the laser and the image sensor are always at an angle with each other. Teledyne DALSA offers the ability to combine multiple Z-Trak profilers to scan an object from different angles to eliminate occlusion. Laser speckle is also a challenge, which is the inherent noise generated by the laser itself, reducing the resolution of systems.

About the Researcher

Inder Kohli is a Senior Product Manager at Teledyne DALSA. Inder has been instrumental in bringing several of Teledyne DALSA’s leading image acquisition and processing hardware and software products to market over his 28 years at the company. For the last five years his focus has been to create a new portfolio 3D imaging products. Inder holds a Bachelor’s Degree in Commerce, a Diploma in Electrical Engineering and, a Certificate in Management Information Systems from McGill University, Canada.

This information has been sourced, reviewed and adapted from materials provided by Teledyne DALSA.

For more information on this source, please visit Teledyne DALSA.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.