A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon. In the broadest sense, it is a device, module, machine, or subsystem that detects events or changes in its environment and sends the information to other electronics. Many of today’s sensors are fabricated using sputtered thin films.

KDF Technologies’ thin film deposition technology is crucial in the fabrication of various sensors and associated products. Applications utilizing thin film coatings in the medical sector include:

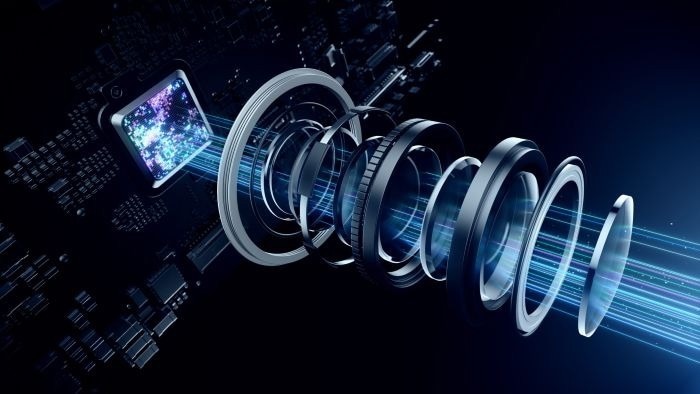

Image Credit: AdobeStock

Switches

Reed Switch: The reed switch is an electromechanical switch widely utilized in proximity sensors. It functions using an applied magnetic field. The switching mechanism comprises two ferromagnetic blades, separated by only a few microns.

When a magnet is brought near these blades, the resulting magnetic attraction closes the normally open (NO) contacts and allows electricity to flow.

Certain reed switches feature a non-ferromagnetic contact for a normally closed (NC) output. KDF Technologies has been a key supplier of thin film sputtering equipment to the reed switch market.

Sensors

Integrated Waveguide Sensors via Sol-Gel Thin Films

These sensors integrate optical and chemical sensing, providing benefits such as portability, cost-efficiency, and in-situ measurements.

Sol-gel chemistry and top-down processing of sol-gel thin film layers are utilized to develop waveguide-based optical sensors.

Porous sol-gel materials can act as claddings and as waveguides with enhanced light-analyte interaction, improving both sensitivity and selectivity.

Image Credit: KDF Technologies, LLC

Refractive Index Sensors and Spectroscopic Sensors

On-chip optical chemical sensors rely on evanescent field-analyte interaction.

In waveguide-based devices, guided light interacts with the surrounding environment via the evanescent field. Interaction may cause phase change or modify the intensity of the incident light.

These sensors are utilized for refractive index measurements and spectroscopic evaluation (including IR absorption and Raman spectroscopy).

Image Credit: AdobeStock

Polymers Thin Film Sensors

Polyaniline (PANI) thin films are employed in chemical sensors owing to their increased surface area and rapid response time.

PANI thin films can be applied with precision onto substrates, making them appropriate for sensing stages in chemical sensors.

High-Temperature Strain Sensors

Thin film gauges using materials such as PdCr function at high temperatures (up to 1100 °C).

These sensors demonstrate superior performance compared to commercially available technologies, withstanding fatigue tests and cyclic strain up to 700 Hz at elevated temperatures.

Image Credit: KDF Technologies, LLC

Image Credit: KDF Technologies, LLC

Image Credit: KDF Technologies, LLC

Image Credit: KDF Technologies, LLC

This information has been sourced, reviewed and adapted from materials provided by KDF Technologies, LLC.

For more information on this source, please visit KDF Technologies, LLC.