Feb 12 2019

A group of physicists from Immanuel Kant Baltic Federal University have collaborated with their counterparts from National Research Nuclear University MEPhI (NRNU MEPhI) to develop a tungsten oxide-based detector for detecting hydrogen in gas mixes.

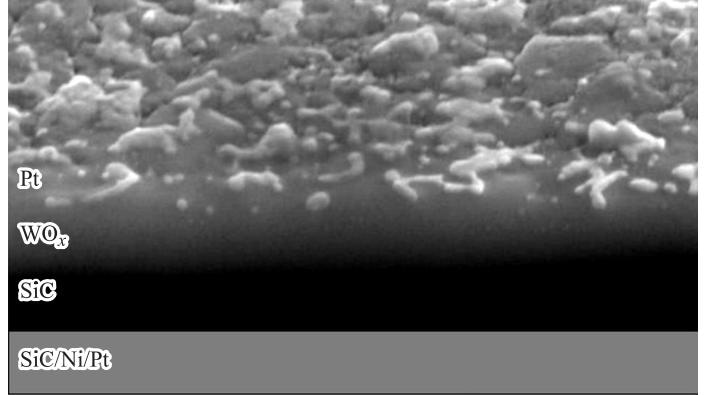

This the morphology of the Pt/WOx/SiC structure. (Image credit: V.V. Zuyev et al./a letter to the Journal of Technical Physics, 2015)

This the morphology of the Pt/WOx/SiC structure. (Image credit: V.V. Zuyev et al./a letter to the Journal of Technical Physics, 2015)

They developed thin tungsten oxide films with different additives and compared their properties. One of the film detectors exhibited a 100 times improvement in sensitivity than a control sample. The study was reported in the Thin Solid Films journal.

The molecules of hydrogen, which is one among the most extensively used gases across the globe, have the smallest possible size and mass. Consequently, it is very difficult to store hydrogen in any vessel, as it leaks from nearly any opening. In industries, hydrogen leakages are extremely dangerous as hydrogen combined with oxygen forms an explosive cocktail called the detonating gas. Leakage prevention turned out to be a raging issue with the advancement of the hydrogen energy sector. Furthermore, hydrogen is dynamically used in controlled nuclear fusion experiments and in chemical industry.

In order to prevent hydrogen leakages, it is essential to constantly monitor its concentration in an industrial facility. In general, it is performed using different types of gas detectors, the most well-known of which are amperometric analyzers. They are based on the potential of gases to alter the electrical conductivity of metals upon coming into contact with them.

During the measurements, fixed voltage is applied to a metal plate’s ends, and a device evaluates the strength of current that passes through it. Since the strength of current is directly dependent on a material’s conductivity, with an increase in the concentration of hydrogen, it also changes. The sensitivity of measurements is established by the sensor’s properties, that is, the plate under voltage.

BFU researchers collaborated with their counterparts from NRNU MEPhI and investigated new materials based on tungsten oxide (WOx). One of the materials was acquired by depositing WOx on a silicone carbide (SiC) substrate. One more material was created in the same way, but an additional platinum coating was used for covering the tungsten oxide layer.

Afterward, the researchers established the sensitivity of the two films by applying voltage to the films and placing the films in an oxygen environment. Following this, 2% of hydrogen was added to it. The material that lacked the platinum coating showed a 15 times increase in the current strength in contrast to pure tungsten oxide. Measurement of the same property in the second material demonstrated a 100 times increase.

We have studied nanomaterials that may be used as a basis for hydrogen leakage sensors. In the course of our work, we identified the requirements for the structural properties of these materials that should secure high gas detecting efficiency.

Dr Alexander Goikhman, Head, Research and Educational Center “Functional Nanomaterials”

Goikhman is also a co-author of the study.